Sludge reduction treatment system and method

A sludge reduction and treatment system technology, applied in the field of pollutant treatment, can solve the problems of large floor area, secondary pollution, high cost, etc., and achieve the effects of low cost, reduced moisture content, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

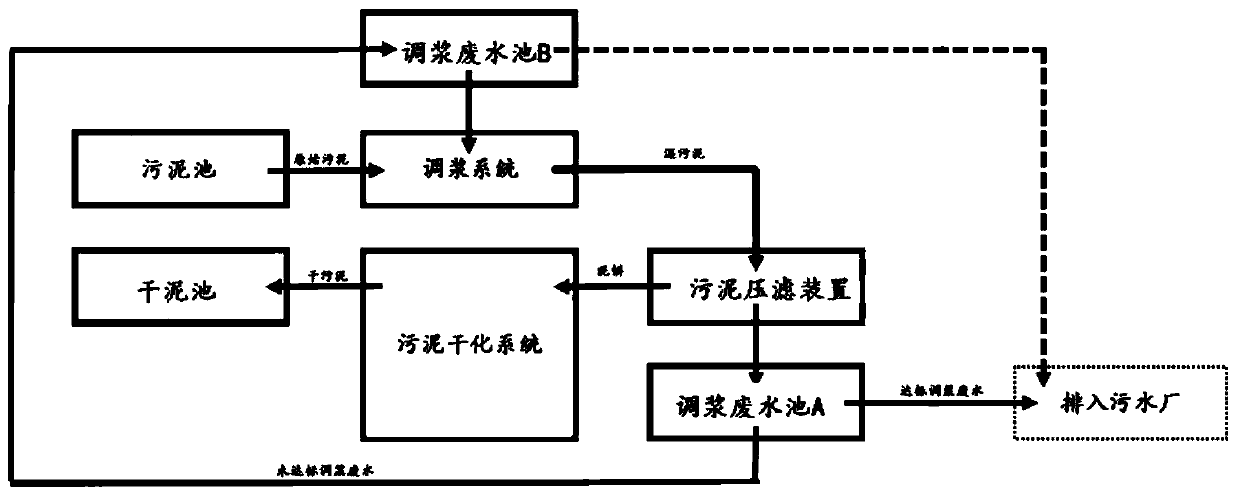

Image

Examples

Embodiment 1

[0048] The method for the sludge reduction treatment of the present embodiment comprises the following steps:

[0049] (1) m tons of raw sludge with a moisture content of 80% is transported to the pulping system for pulping treatment to obtain wet sludge with a moisture content of 90%;

[0050] (2) Transport the wet sludge to the plate and frame filter press, dehydrate and press it into a mud cake, separate and obtain m tons of pulping wastewater and mud cake with a water content of 60%, m tons of pulping wastewater, and its water quality The indicators are shown in Table 1:

[0051] Table 1

[0052] COD (mg / L) BOD 5 (mg / L)

NH 4 -N (mg / L)

SS(mg / L) 400 100 100 200

[0053] The influent standards of the actual sewage plant are shown in Table 2:

[0054] Table 2

[0055] COD (mg / L) BOD 5 (mg / L)

NH 4 -N (mg / L)

SS(mg / L) 300 80 70 120

[0056] Apparently, the water quality of pulping wastewater obviously does...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com