One-stop pulper

A pulper, stand-type technology, applied in mixers, mixer accessories, mixers with rotating containers, etc., can solve the problems of low pulping work efficiency and low pulp yield, and achieve high work efficiency and pulp. The effect of high material yield, reduction of reaction energy consumption and production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

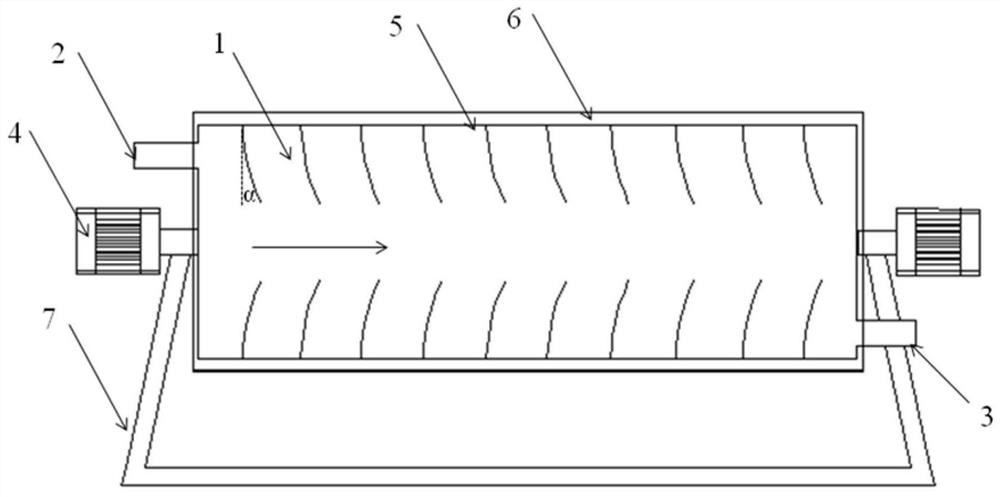

[0032] Such as figure 1 The one-stop horizontal pulping machine shown includes a body, a flap 1, a feed port 2, a discharge port 3 and a motor 4; the body is composed of an inner casing 5 and an outer casing 6; the flap 1 is arranged on On the inner wall of the inner casing 5, the turning plate 1 is set at an angle so that it tends to the conveying direction of the material in the inner casing 5; the motor 4 is arranged at the end of the body, and is used to drive the inner casing to rotate along the horizontal central axis; The material inlet 3 is arranged at one end of the machine body, the material outlet 2 is arranged at the other end of the machine body, and the material inlet 2 and the material outlet 3 communicate with the inner casing 5 .

[0033] The flaps 1 are evenly arranged on the inner wall of the inner casing 5 by welding, and the distribution density of the flaps 1 on the inner wall of the inner casing 5 is 10 pieces / m 2 , the distance between every two flaps ...

Embodiment 2

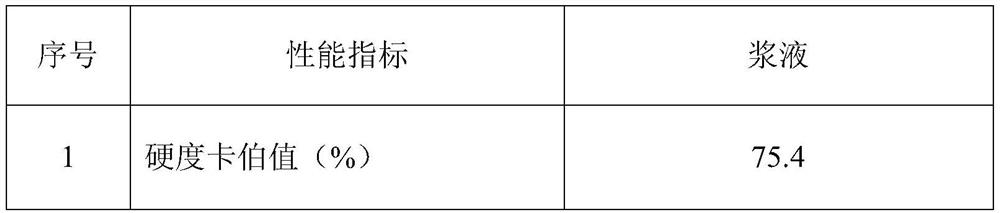

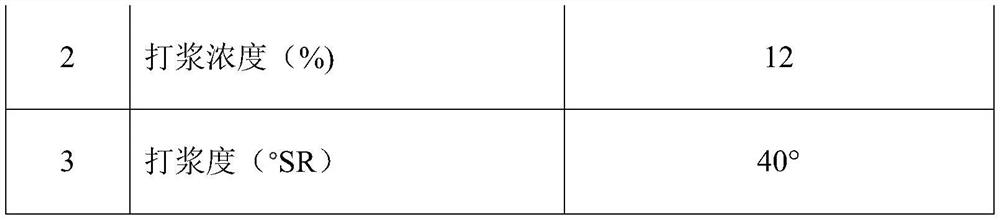

[0040] The use method of the one-stop pulping machine includes the following steps: select dry straw, remove impurities and dust, and crush 2.5t of straw with a length of 2-5 cm and 3.2t of chemical agents (chemical agents include 2.9t of clear water, 0.2 t of sodium hydroxide t and hydrogen peroxide (0.1t) are continuously fed into the pulper in Example 1 simultaneously, and the feeding time is 130 minutes (feed rate is 2627kg / h), mixed and rotated in the pulper, reacted into slurry, and obtained The pulp is continuously discharged from the pulper.

[0041] The screw rod is used to feed the material, and the chemical agent is sprayed on the rice straw before the straw enters the entrance of the pulper.

[0042] The speed at which the inner housing rotates is 100 revolutions per minute. The rotation speed should not be too fast, otherwise it will not be conducive to fully reacting into slurry. Rice straw and chemicals enter the pulping machine, using the contact reaction of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com