Secondary combustion chamber for household garbage flue gas

A secondary combustion chamber and domestic waste technology, applied in the combustion method, combustion type, incinerator, etc., can solve the problems of increased operating costs, insufficient residence time, unstable flue gas temperature, etc., to achieve stable combustion, not easy to smoke The effect of blockage and easy dust cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

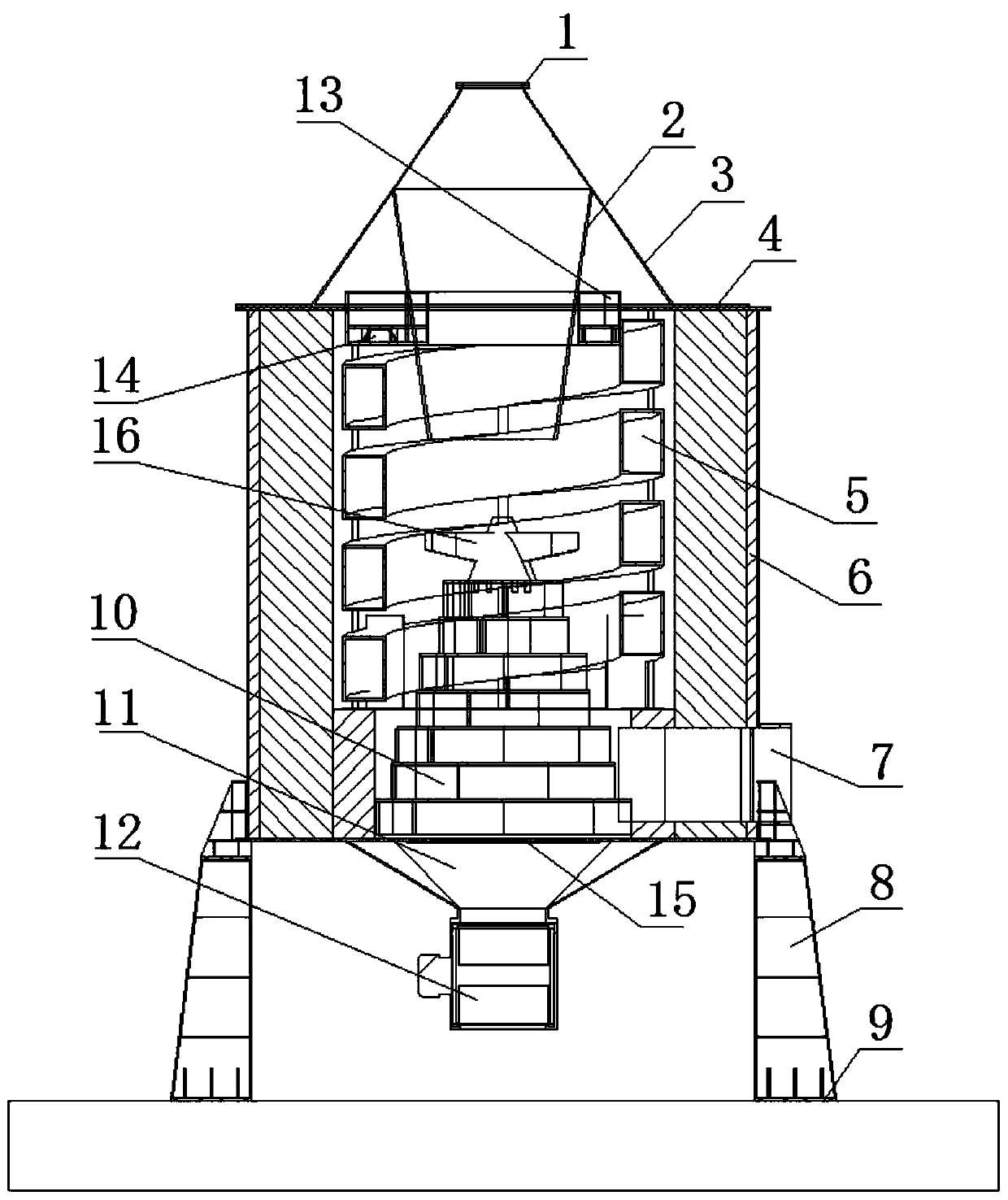

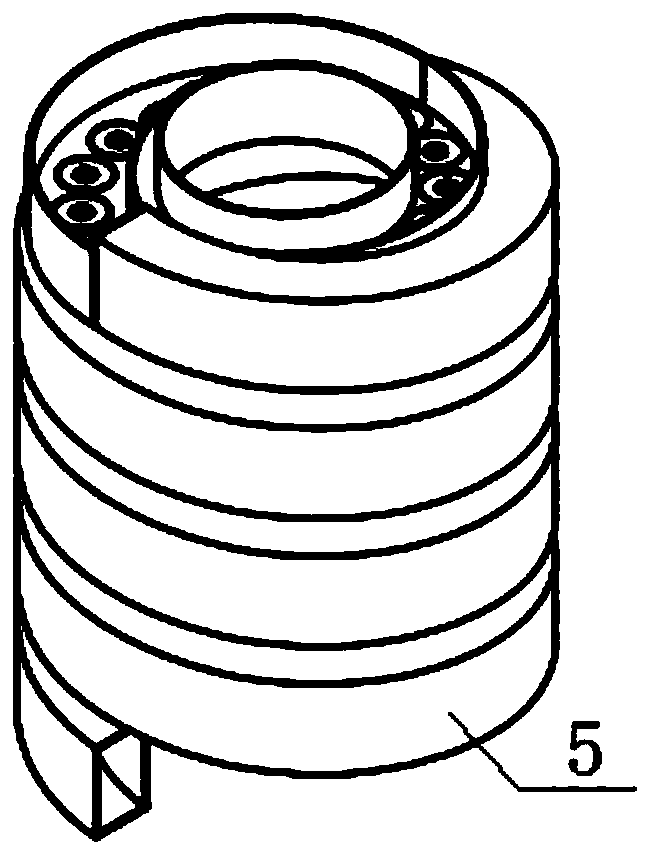

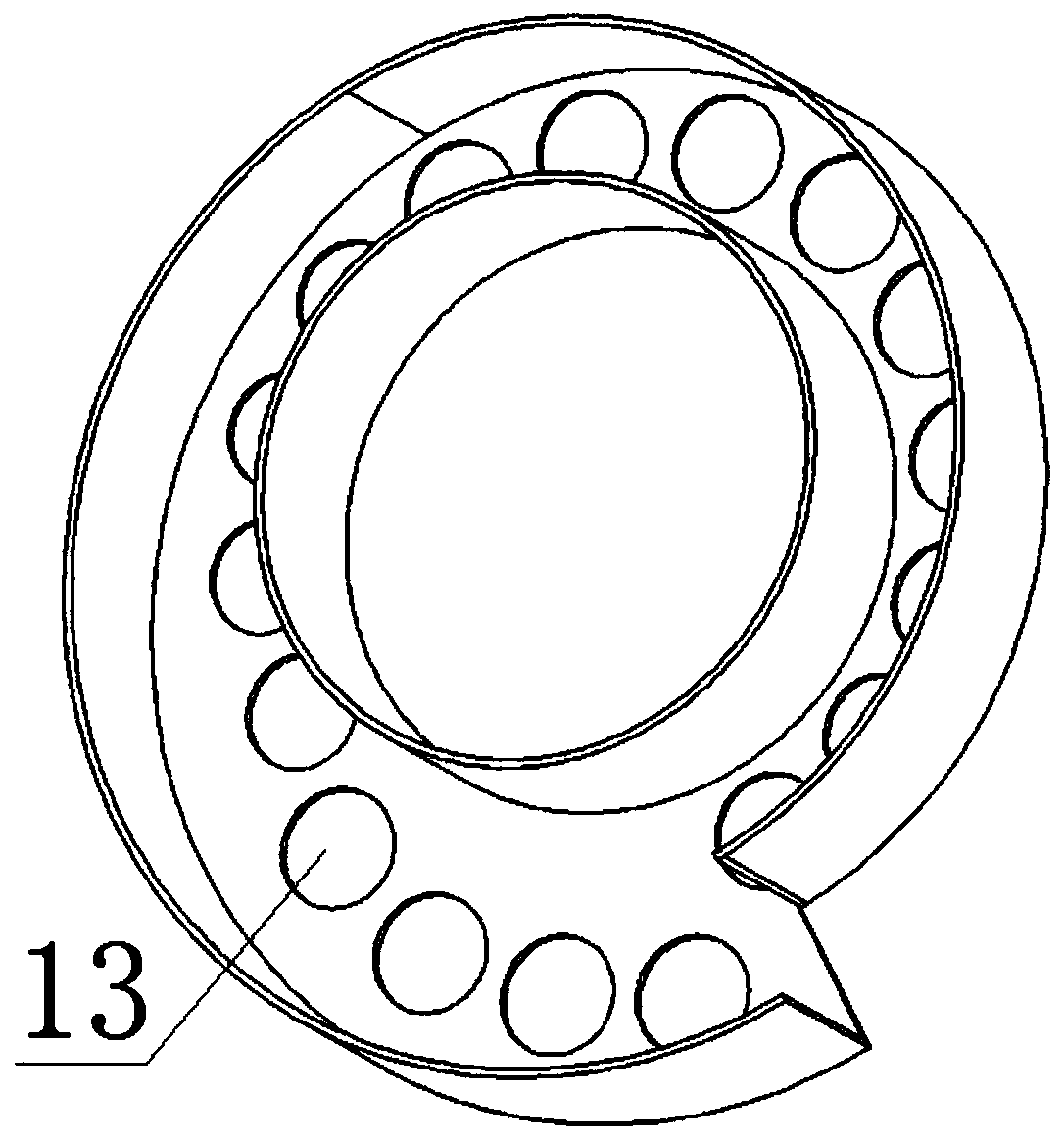

[0022] refer to Figure 1-4 , a secondary combustion chamber for flue gas from domestic waste, comprising a heat-insulating sealing cover flange 1, a preheating conical cover 2, a heat-insulating sealing cover 3, a refractory and heat-insulating material 4, a secondary combustion chamber cavity 5, an outer shell 6, Furnace door 7, furnace leg 8, pre-embedded connecting plate 9, 360-degree air inlet grate 10, ash remover 11, slag remover 12, suffocating flue 13, porous high-temperature heat storage body 14, the heat preservation and sealing cover method Lan 1 is connected by bolts, and the gasket is made of thermal insulation aluminum silicate wool, which can ensure better sealing performance while maintaining thermal insulation and fire resistance. The preheating conical cover 2 is made of special high-temperature-resistant steel, the outer surface is poured with refractory material, and the inner surface is smooth steel. The heat preservation sealing cover 3 is a conical str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com