Millimeter wave printed dipole antenna array radiating element and array antenna

A dipole antenna and radiating unit technology, applied in the antenna array, radiating element structure, antenna and other directions, can solve the problems of narrow frequency band, inconvenient power feeding, small antenna size, etc., to achieve enhanced radiation and receiving capabilities, and convenient Feed, easy processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

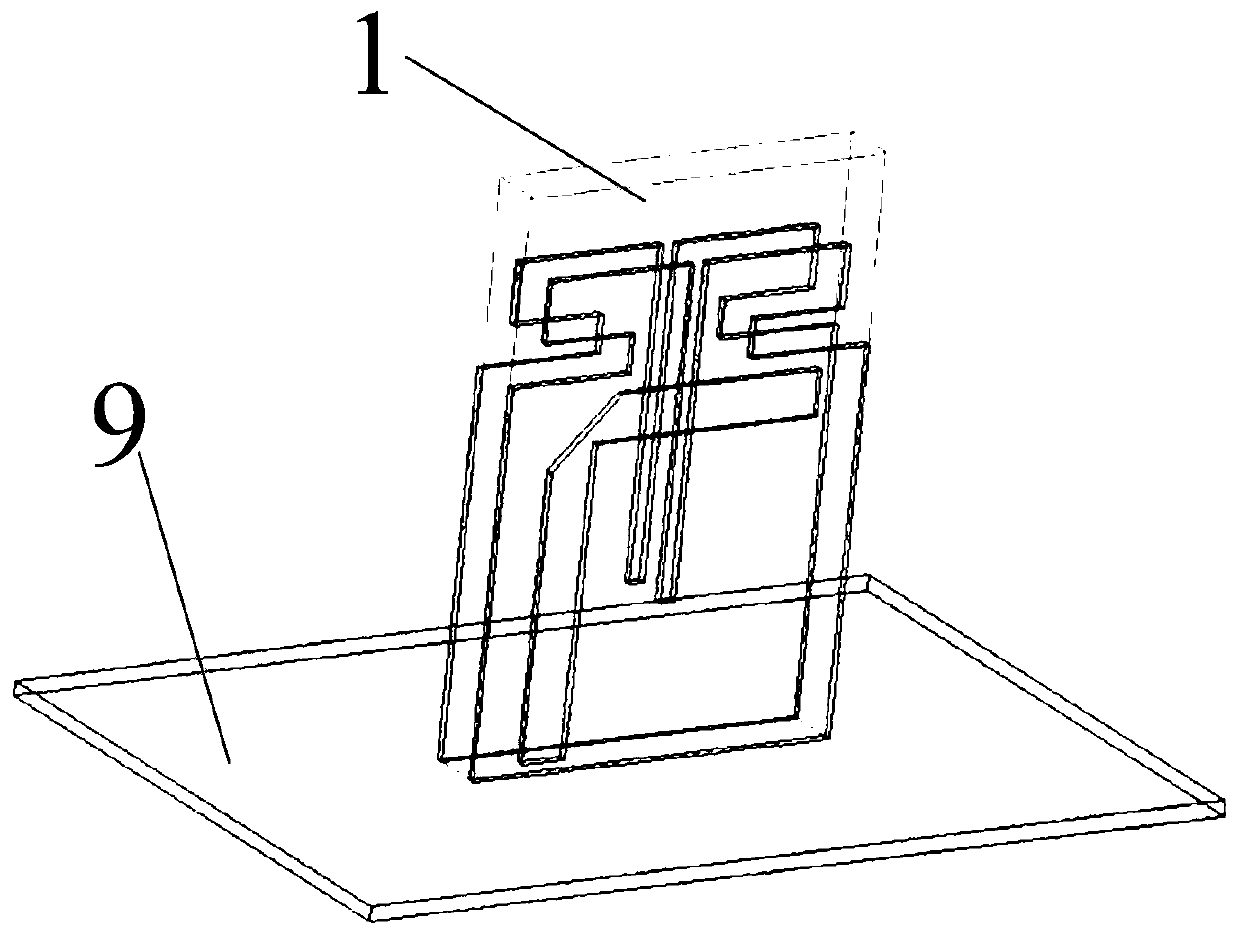

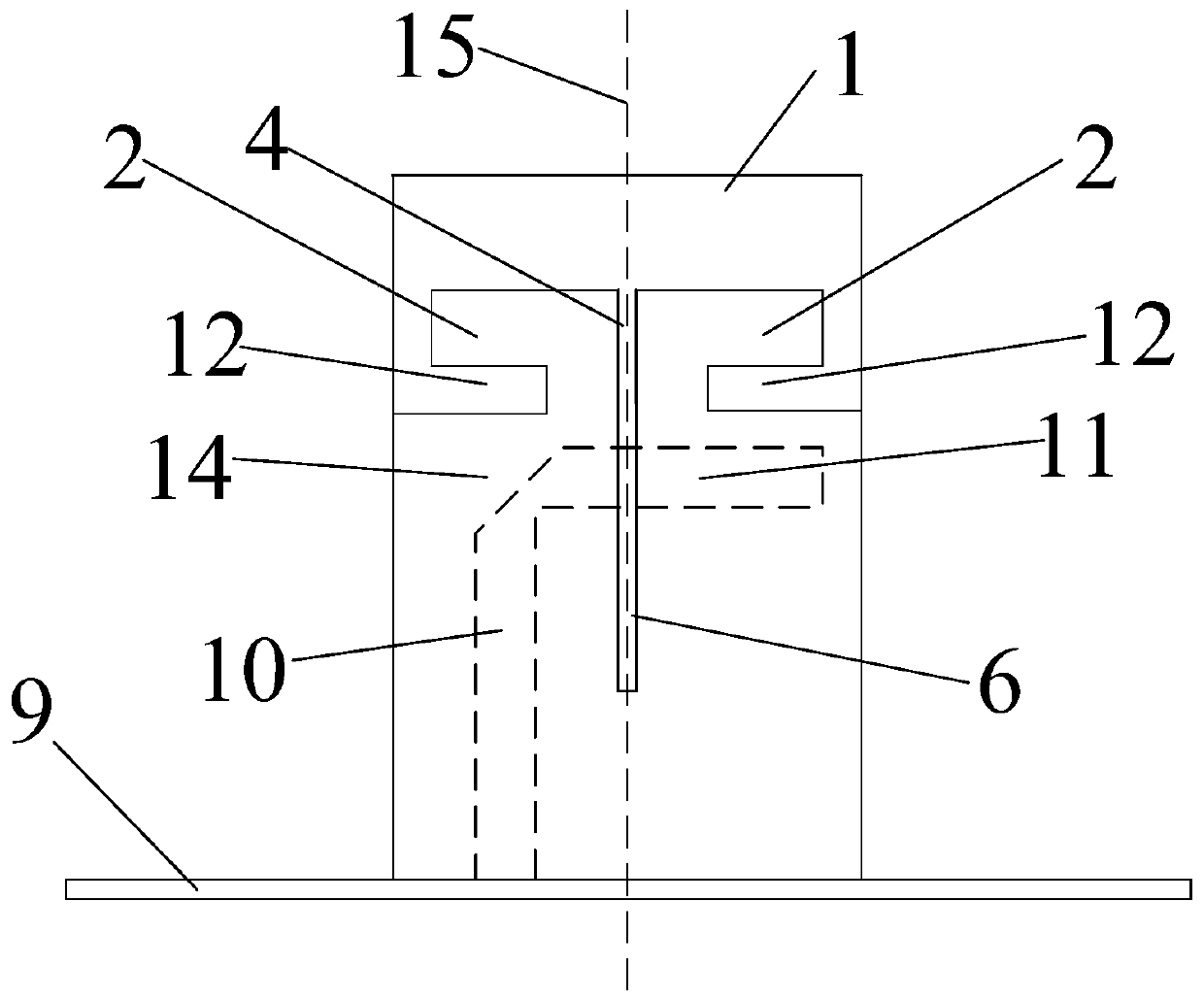

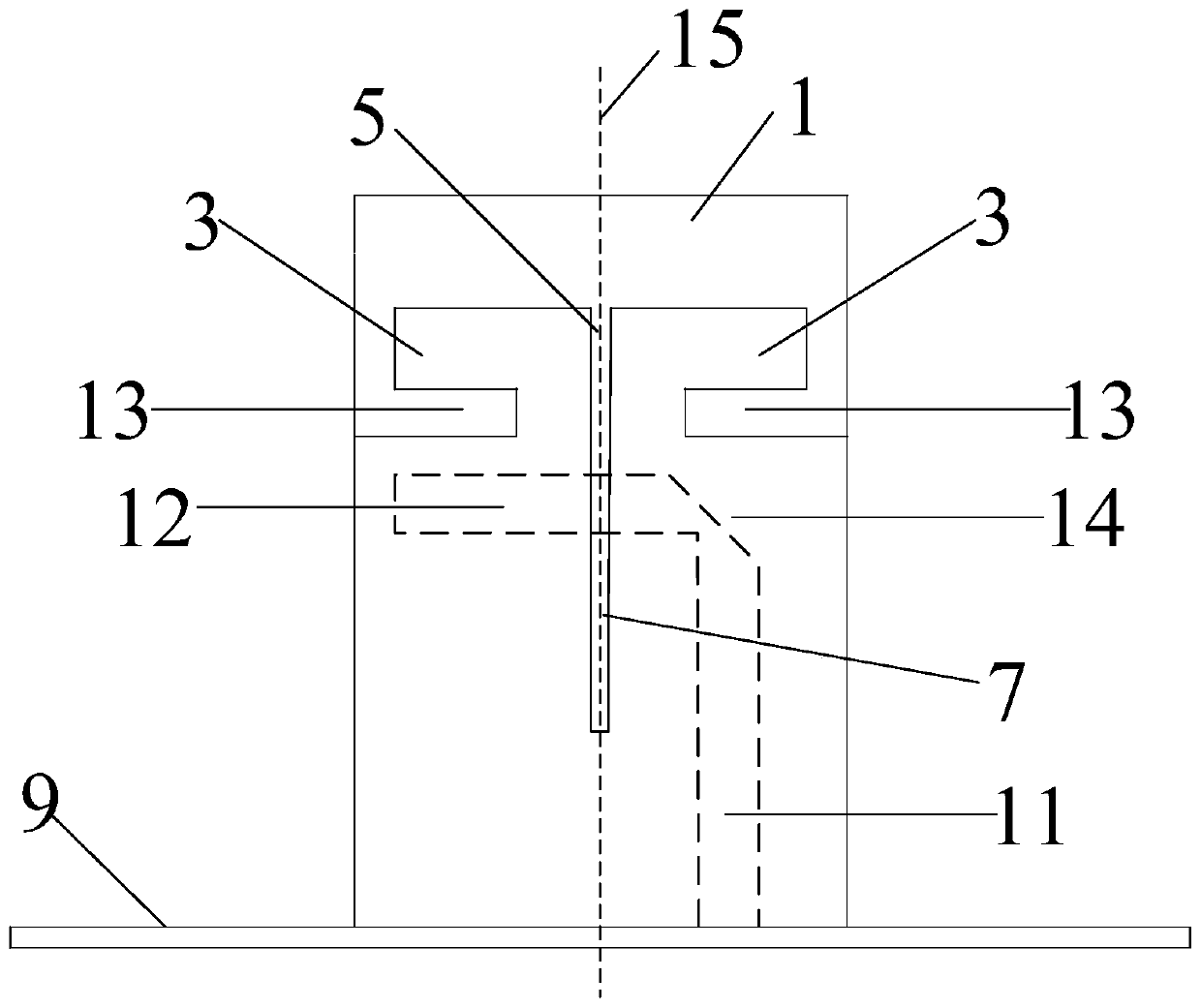

[0030] A millimeter-wave printed dipole antenna array radiating unit according to an embodiment of the present invention includes a dielectric substrate 1, a feeding stripline 8 and two dipole antennas, and the middle of the two radiating arms of the dipole antenna is The position is provided with a slit; each of the two board surfaces of the dielectric substrate 1 is printed with one dipole antenna, and the feeding stripline 8 is arranged in the dielectric substrate 1 and is located between the two The position between the dipole antennas is parallel to the surface of the dielectric substrate 1; the feeding stripline 8 intersects the projection of the slot at the lamination angle.

[0031] First of all, a dipole antenna is printed on each of the two board surfaces of the dielectric substrate 1, which enhances the radiation and reception capabilities of the dipole antenna. Secondly, due to the projection and gap of the feeding stripline 8 in the horizontal direction The projec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com