Baking-resistant sandwich jam and preparation method thereof

A sandwich sauce and baking tong technology, which is applied in the field of bake-resistant sandwich sauce and its preparation, can solve the problems of short shelf life, high sugar content, strong paste taste, etc., and achieve the effect of optimized stability, soft taste and rich flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0071] In addition, the present invention also proposes a preparation method of baking-resistant sandwich sauce, said method comprising:

[0072] ① Mix sugar, edible salt, monosodium glutamate, maltodextrin, preservatives, and pigments evenly to obtain powder mixture A1; in actual preparation, these raw materials are mixed together to fully mix and dissolve with enzymatic egg liquid to form Basic stable liquid phase system;

[0073] ②Mix the essence, sour agent, sweetener, antioxidant, pregelatinized starch and edible colloid evenly to obtain the powder mixture A2; this step can make these raw materials mixed with the mixed oil body C and disperse evenly to enhance the stability of the sauce consistency and smoothness, while also enhancing the sauce body flavor and aftertaste;

[0074] ③ After fully mixing the enzymatic egg liquid and water, set the temperature at 15-20°C, let stand at a constant temperature for 5-8 minutes, add the powder mixture A1, stir at medium speed und...

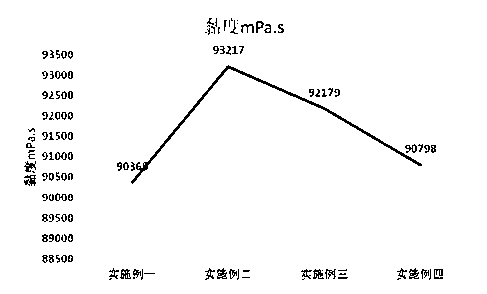

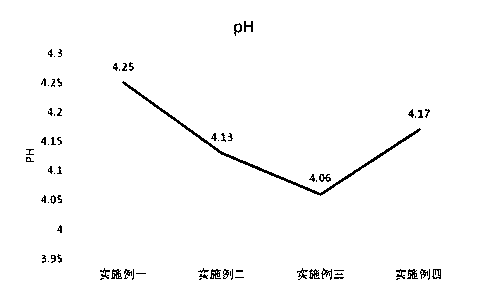

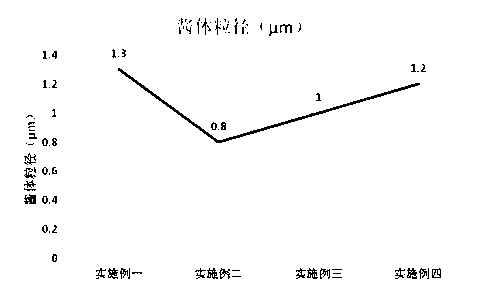

Embodiment 1

[0084] ① Mix sugar, edible salt, monosodium glutamate, maltodextrin, preservatives, and pigments evenly to obtain powder mixture A1;

[0085] ②Mix the essence, sour agent, sweetener, antioxidant, pregelatinized starch and edible colloid evenly to obtain powder mixture A2;

[0086] ③ After fully mixing the enzymatic egg liquid and water, set the temperature at 15°C, let stand at constant temperature for 8 minutes, add powder mixture A1, stir at medium speed for 10 minutes under vacuum conditions, fully dissolve and mix evenly, and obtain liquid material B ;

[0087] ④Mix salad oil, glycerin and emulsifier evenly to obtain mixed oil body C;

[0088] ⑤ Slowly add the powder mixture A2 into the mixed oil body C, stir at a low speed for 5 minutes, then slowly add the liquid material B, and stir at a high speed for 10 minutes, and mix all the materials evenly to obtain a semi-finished sauce;

[0089] ⑥ Pour the semi-finished sauce body obtained in ④ into a water-bath cooking pot a...

Embodiment 2

[0093] ① Mix sugar, edible salt, monosodium glutamate, maltodextrin, preservatives, and pigments evenly to obtain powder mixture A1;

[0094] ②Mix the essence, sour agent, sweetener, antioxidant, pregelatinized starch and edible colloid evenly to obtain powder mixture A2;

[0095] ③After fully mixing the enzymatic egg liquid and water, set the temperature at 18°C, keep it at a constant temperature for 6 minutes, add the powder mixture A1, stir at a medium speed under vacuum for 9 minutes, fully dissolve and mix evenly, and obtain liquid material B ;

[0096] ④Mix salad oil, glycerin and emulsifier evenly to obtain mixed oil body C;

[0097] ⑤ Slowly add the powder mixture A2 into the mixed oil body C, stir at a low speed for 9 minutes, then slowly add the liquid material B, and stir at a high speed for 18 minutes, and mix all the materials evenly to obtain a semi-finished sauce;

[0098] ⑥ Pour the semi-finished sauce body obtained in ④ into a water-bath cooking pot and heat i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com