Pure titanium metal dental crown, restoration body and processing method thereof

A processing method and crown technology, applied in the field of oral restoration, can solve the problems of restoration failure, inconsistent wear performance of restoration materials and natural tooth enamel, excessive wear, etc., to achieve aggravated abrasive wear and adhesive wear, stable and good occlusal relationship, Uniform effect of dissolution and erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

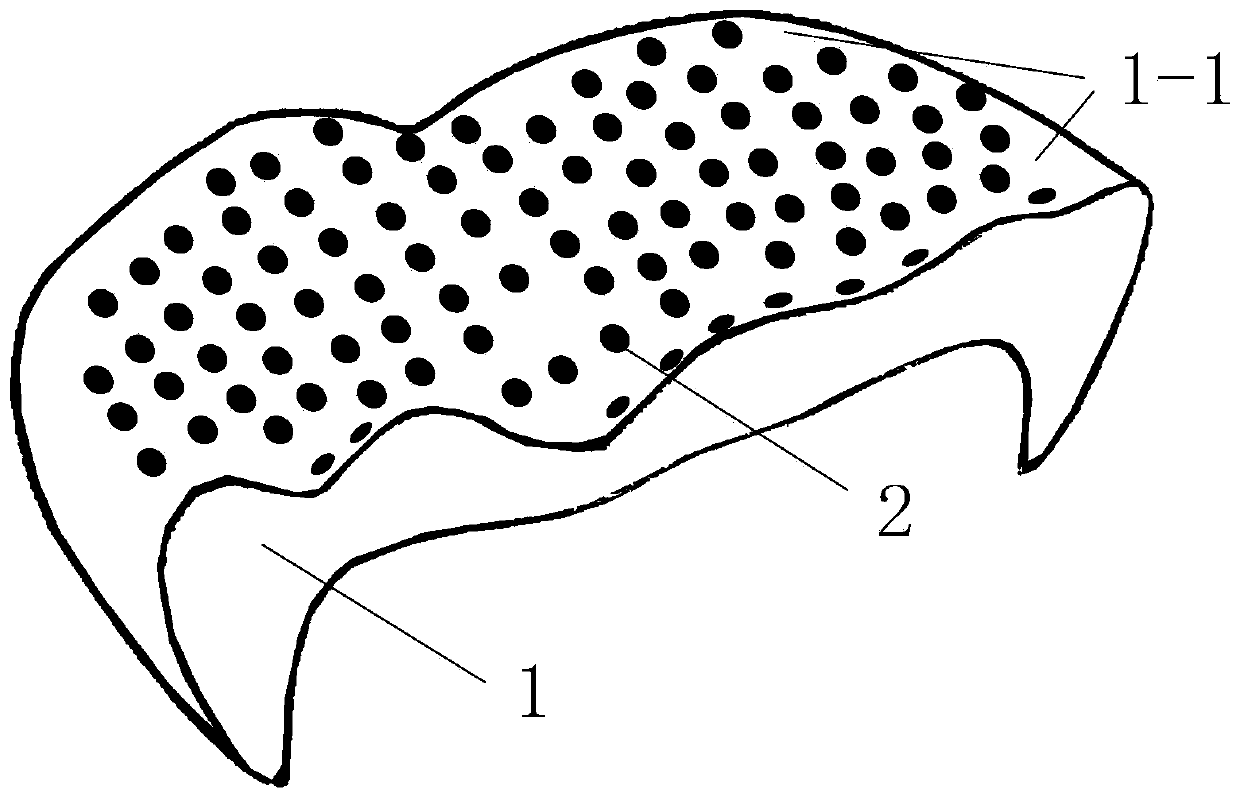

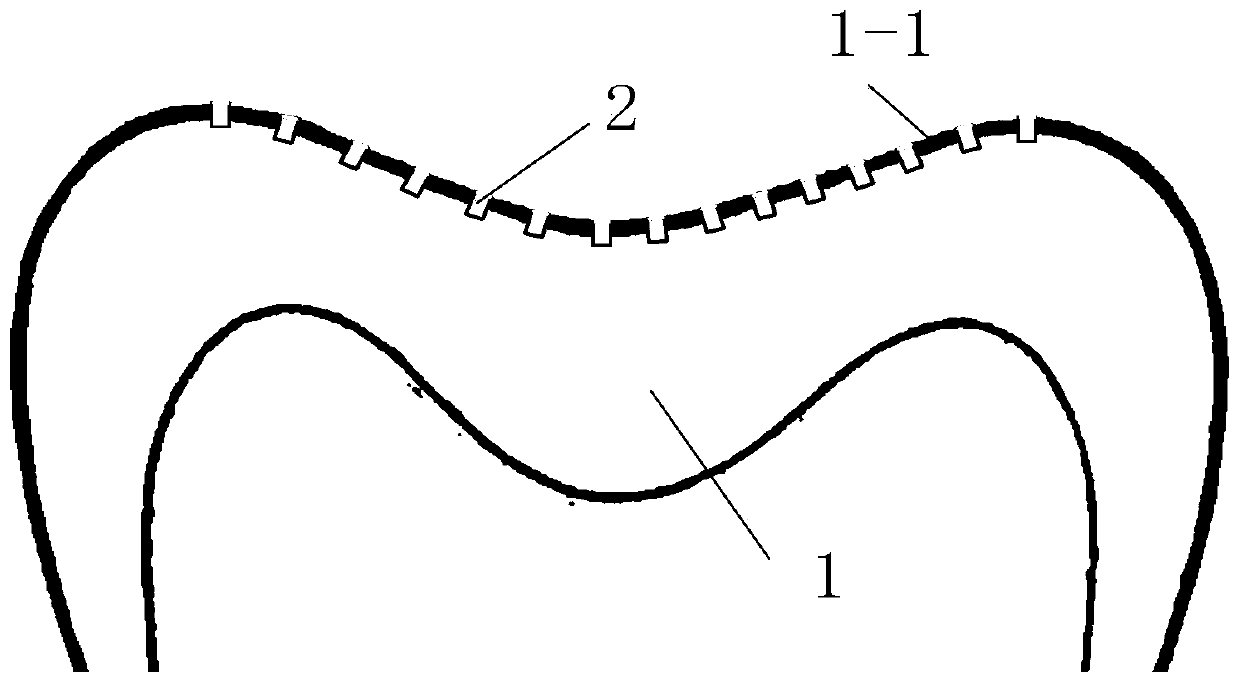

Examples

Embodiment 2

[0040] This embodiment discloses a prosthesis, including an implant and the pure titanium crown described in Example 1, the implant is connected to the pure titanium crown, and the implant is an existing prosthetic implant, namely Yes, it can be implanted in the upper and lower jaws of the human body where the teeth are missing. Yes, no detailed description is given here.

Embodiment 3

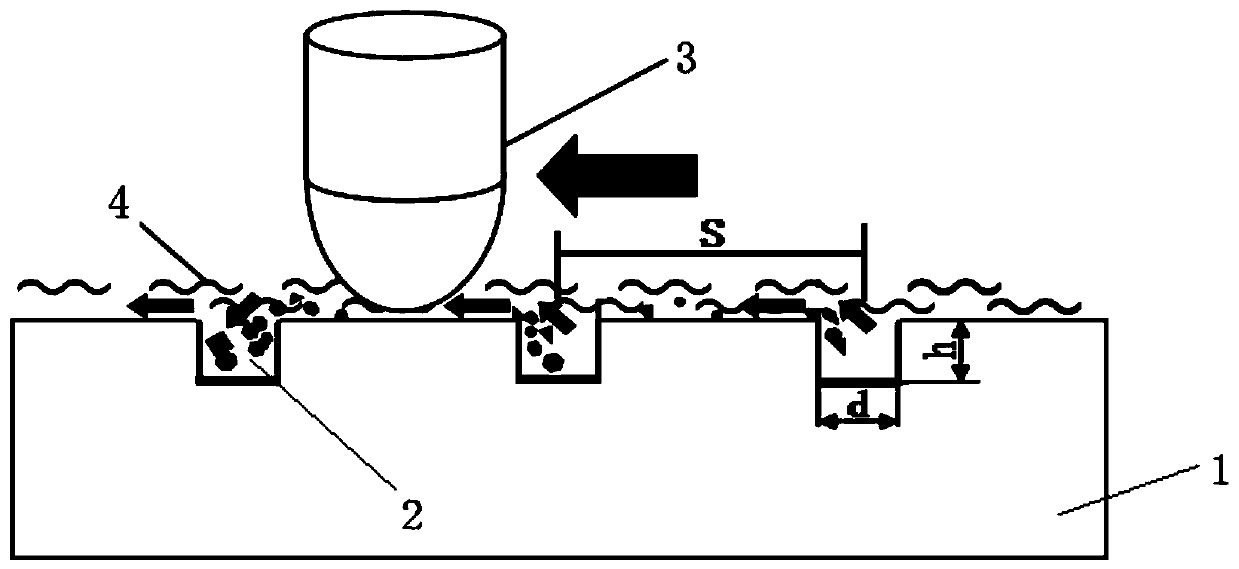

[0042] This embodiment discloses a processing method of a pure titanium crown, such as Figure 4 shown, including the following steps:

[0043]Step 1: Immerse the crown body 1 made of pure titanium in an alcohol solution, and perform ultrasonic cleaning for 10 minutes.

[0044] Step 2: Put the cleaned crown body into a drying oven and bake it at 100°C until the surface is completely dry.

[0045] Step 3: Place the dry crown body on a 1500r / min rotary glue leveling table for glue coating, and use the centrifugal force to evenly coat the photoresist on the occlusal surface of the crown body to form a thickness of 3um-5um photoresist film 5, put the crown body coated with photoresist film into a drying oven at 100°C and bake for 20 minutes to improve the adhesion between the crown body and the photoresist film, and ensure the crown body and the photoresist film The resist film is adhesively fixed.

[0046] Step 4: pressing the mask plate 6 on the upper surface of the photoresi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| wear volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com