Aluminum alloy ultrasonic-assisted 3D printing device and printing method thereof

An ultrasonic-assisted, 3D printing technology, applied in the field of 3D printing, can solve the problems of unfavorable properties of metal materials, inability to use ultrasound to promote the wetting and bonding of liquid metals, etc., and achieve high mechanical properties, consistent properties, and improved parts accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

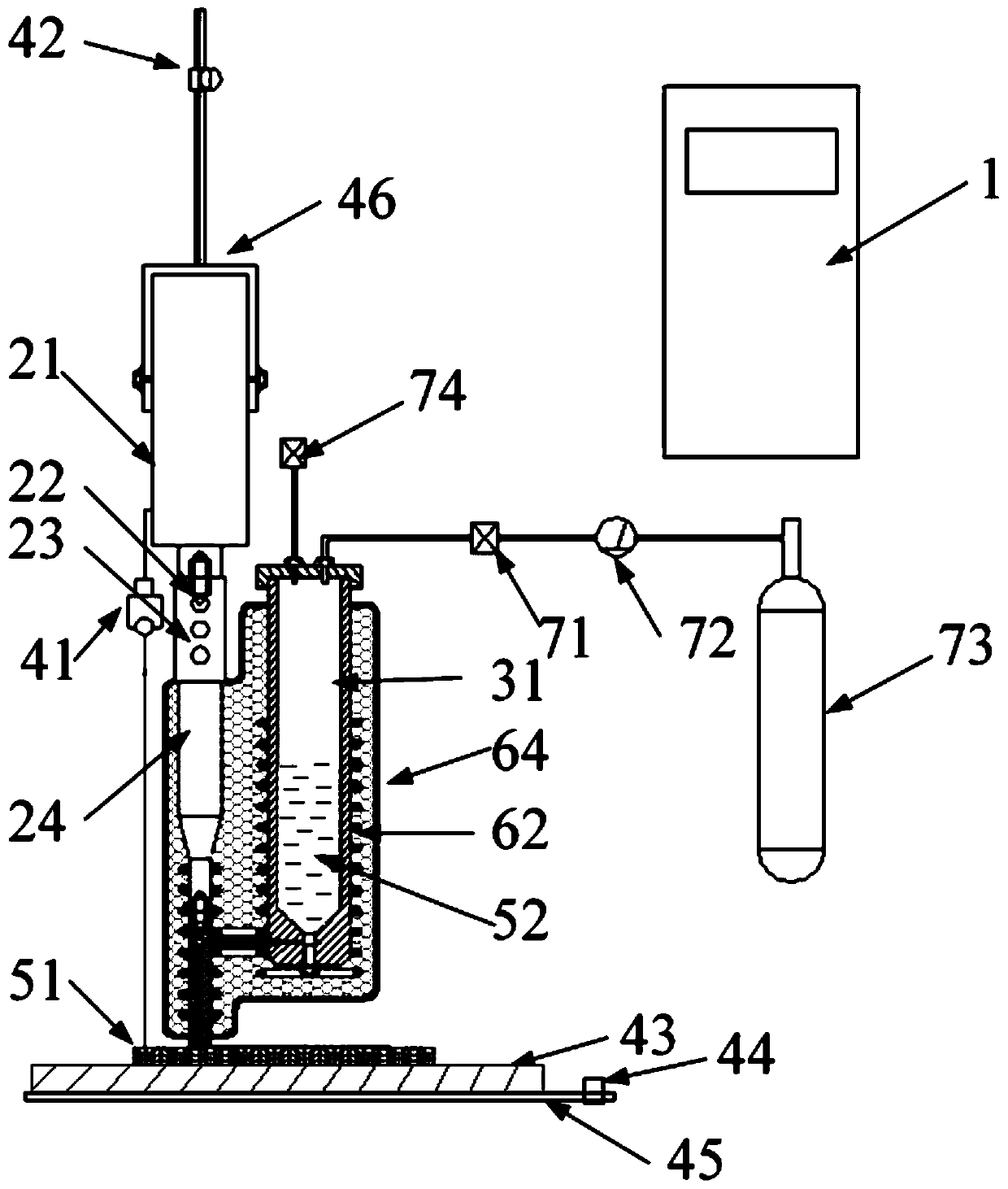

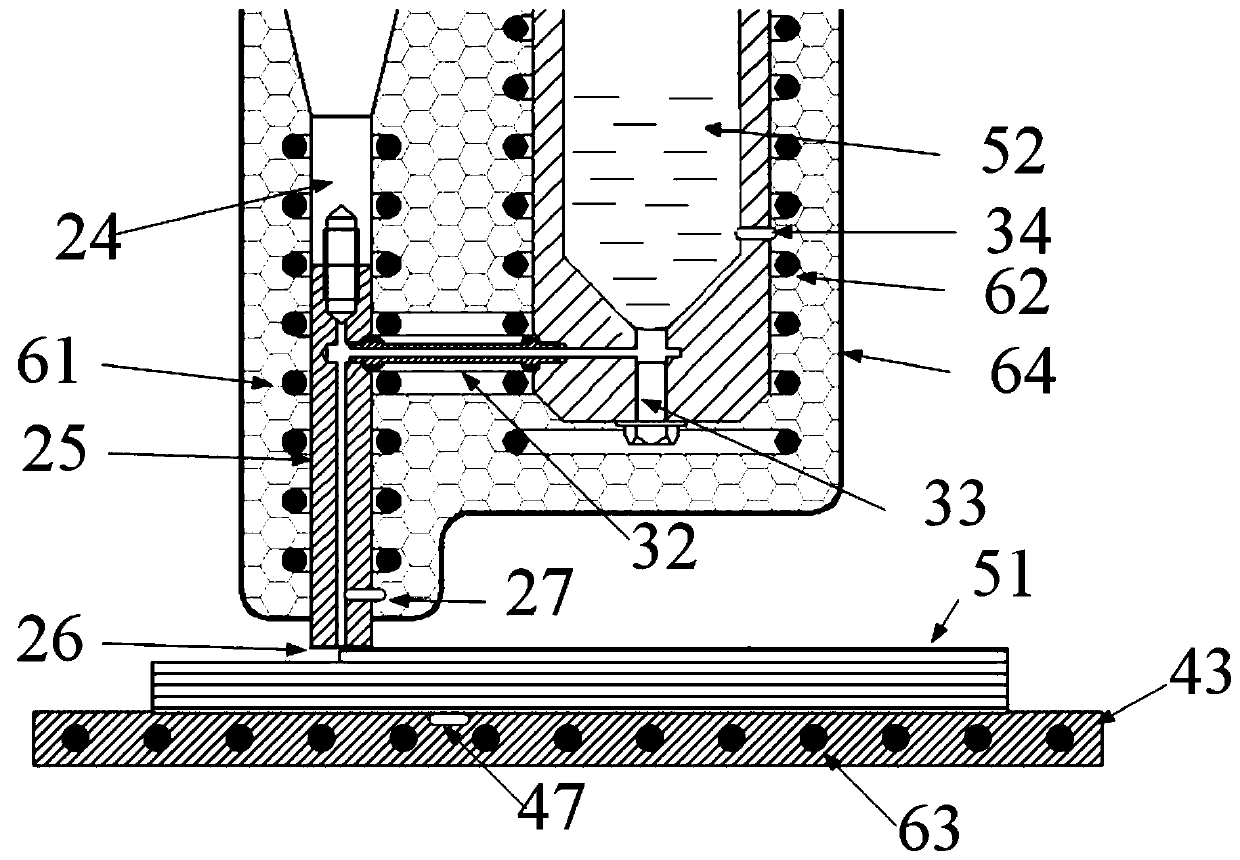

[0043] Specific implementation mode one: combine Figure 1 to Figure 4 Describe this embodiment. The aluminum alloy ultrasonic-assisted 3D printing device in this embodiment includes an industrial control cabinet 1, an ultrasonic-assisted printing module, a storage and delivery module, and a three-dimensional mobile module. The industrial control cabinet is the computer control system of the entire device, and the ultrasonic-assisted printing module, The metal storage tanks 31 of the material storage and conveying module are all fixed on the three-dimensional mobile module to realize three-dimensional printing.

[0044] The ultrasonic auxiliary printing module includes an ultrasonic transducer 21, a cooling water outlet 22, a cooling water inlet 23, a horn 24, an ultrasonic tool head 25, a nozzle 26, a substrate 43, a first temperature sensor 27, and a third temperature sensor 47 , an aluminum alloy part 51, a first heating module 61, a third heating module 63 and a heat insul...

specific Embodiment approach 2

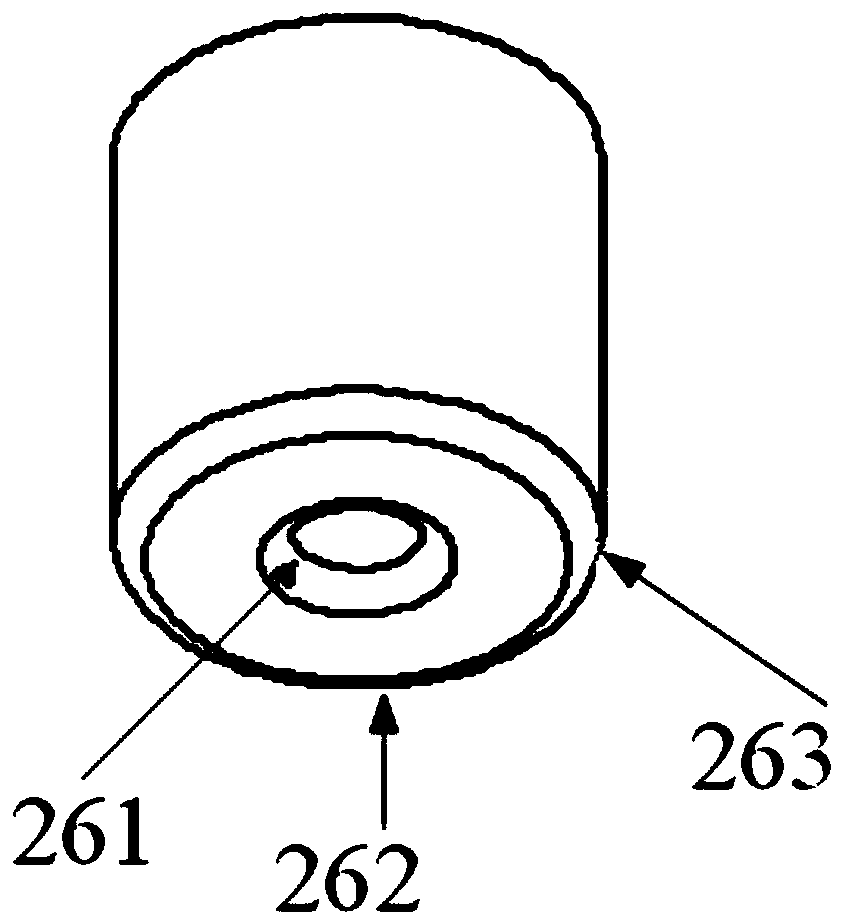

[0047] Specific implementation mode two: combination image 3 and Figure 4 Describe this embodiment, the nozzle 26 on the ultrasonic tool head 25 of this embodiment, the diameter range of the liquid metal outflow pipe at the printing nozzle is 20 μm-1000 μm, the outflow pipe in the printing nozzle and the plane 262 transition with a round chamfer 261, the circle The radius of the chamfer 261 is 50-600 μm. With the movement of the platform, the round chamfer 262 can make the transition of the extrusion process smoother. At the same time, due to the limited distance of the ultrasonic action, the printing distance is generally 100-300 μm. In such a narrow gap The liquid metal tends to flow downward to the plane 262, and the squeezed liquid metal is in close contact with the plane 262. The plane 262 inputs ultrasonic waves into the liquid metal to produce a cavitation effect, and quickly breaks the oxide film on the aluminum surface at a low temperature. micro-fused connection. ...

specific Embodiment approach 3

[0048] Specific implementation mode three: combination Figure 1 to Figure 4 Describe this embodiment. This embodiment provides an ultrasonic-assisted 3D printing method for aluminum-based composite materials. The method selects a temperature 20-100°C higher than the melting point of the metal material to be printed as the printing temperature, and the preheating temperature of the substrate It is 50-200°C lower than the melting point of metal materials, and the printing speed is 5-20cm / min. It can realize the printing of aluminum alloys and parts that are not limited by the size of aluminum alloy raw materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com