Universal tool for assembling and welding car coupler beam

A beam and coupler technology, applied in the field of rail transit car body systems, can solve the problems of increasing the product size, the difficulty of adjusting the shape of components, increasing the grinding of weld joints, and the uncontrollable pressing force, so as to improve the site utilization rate and simplify the Production process, the effect of improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

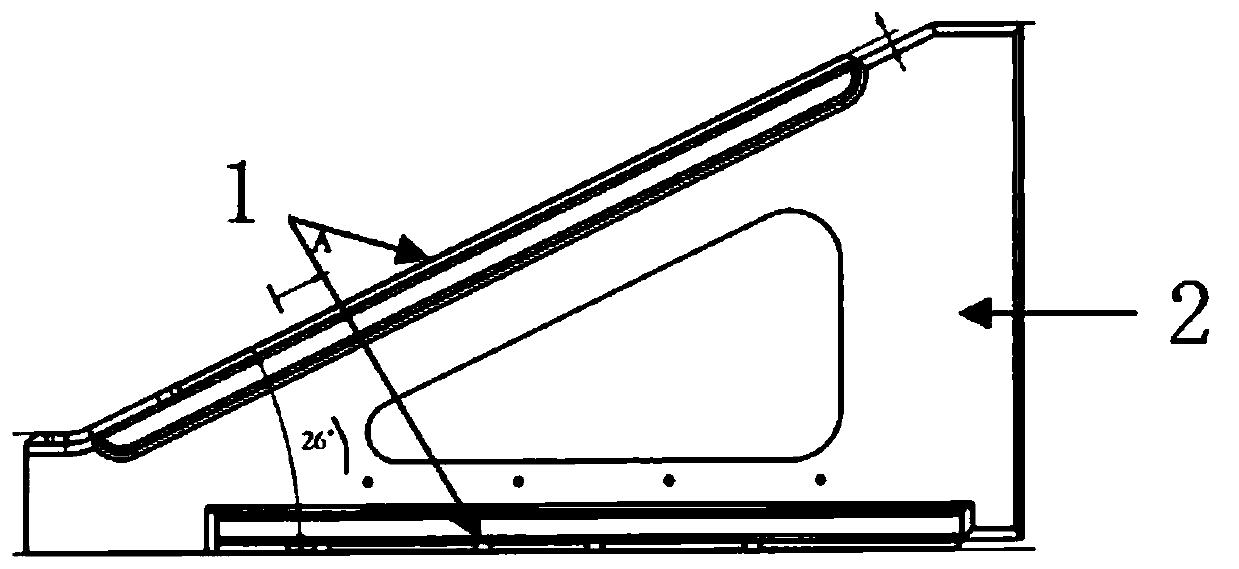

[0023] The universal tooling for assembly and welding of the coupler crossbeam in this embodiment adopts hydraulic pressing and flipping to work, the pressing force is constant, and the anti-deformation angle can be adjusted, which can effectively control the welding deformation of the product.

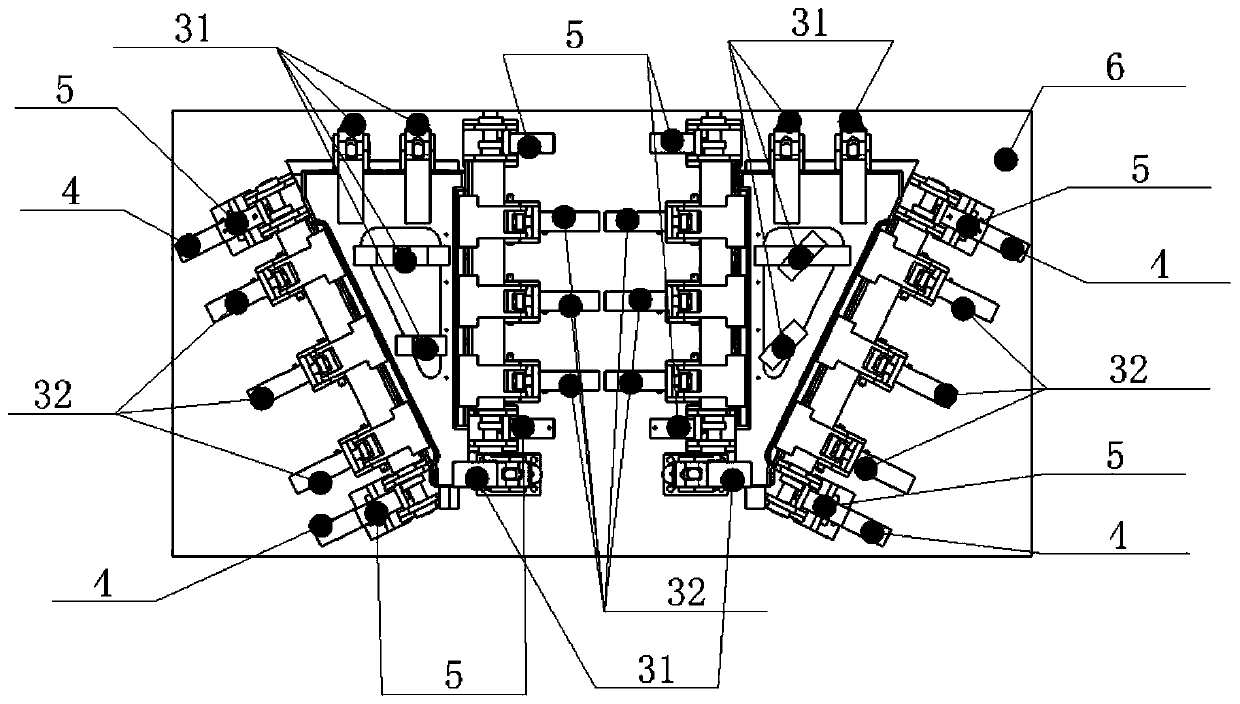

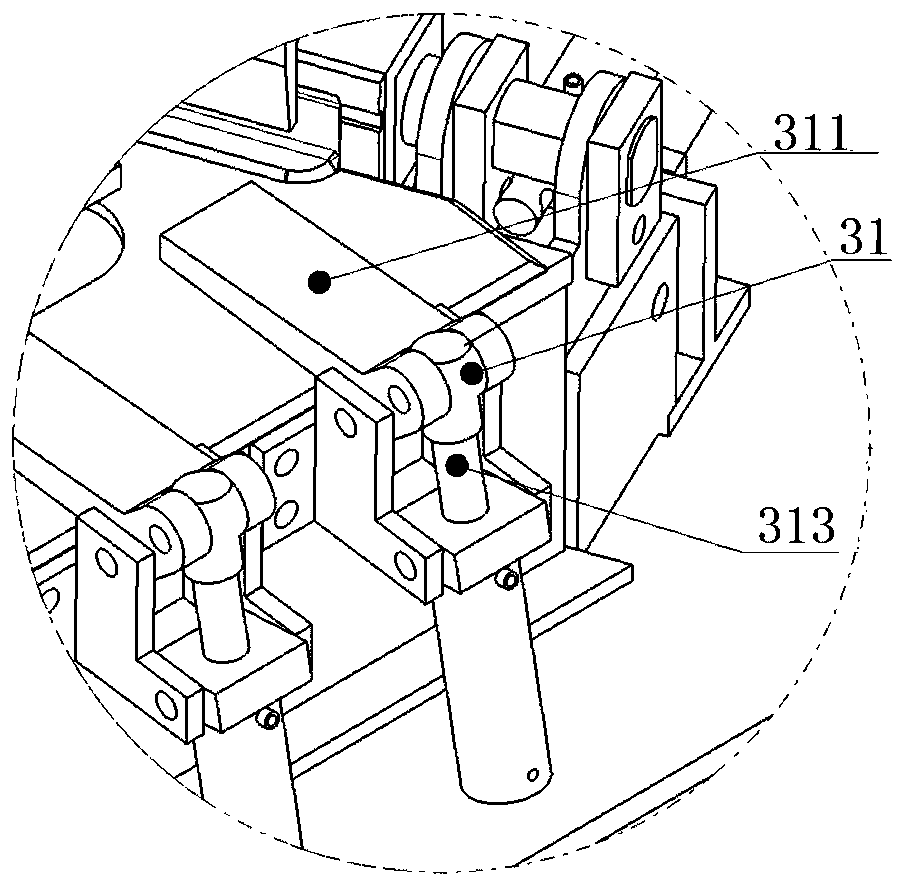

[0024] Such as figure 2 As shown, the universal tooling for assembly and welding of coupler beams in this embodiment includes a platform 6 and a pressing control unit, a pushing control unit and a flipping control unit. The platform 6 is used as a substrate to place other parts of the tooling, that is, other parts are arranged on it. The universal tooling for assembly and welding of the coupler beam is symmetrically set.

[0025] The pressing control unit, the pushing control unit and the overturning control unit are used for clamping and assembling the coupl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com