Treatment method of organic matter in high-salt wastewater

A technology for high-salt wastewater and a treatment method, applied in the field of wastewater treatment, can solve problems such as high chemical oxygen demand discharge standards, human health and environmental threats, and achieve the effects of small external factors, reduced pollutant content, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0044] According to a preferred embodiment of the present invention, the relative humidity of the secondary steam is 0-100%, preferably 45%-100%, more preferably 80%-100%, especially preferably 95%-100%.

[0045] Wherein, the relative humidity is the percentage of the water vapor pressure in the secondary steam and the saturated water vapor pressure.

[0046] The inventors have found through research that the process of the present invention can efficiently degrade secondary steam with a relative humidity of 0 to 100%, especially when the relative humidity of the secondary steam is high (such as 80% to 100%, 95% to 100%), and its photocatalytic oxidation degradation efficiency can still be maintained at a relatively high level.

[0047] According to a preferred embodiment of the present invention, the secondary steam includes volatile organic gases, preferably benzene series volatile organic gases.

[0048] Wherein, a large amount of volatile organic gases in the secondary st...

Embodiment 1

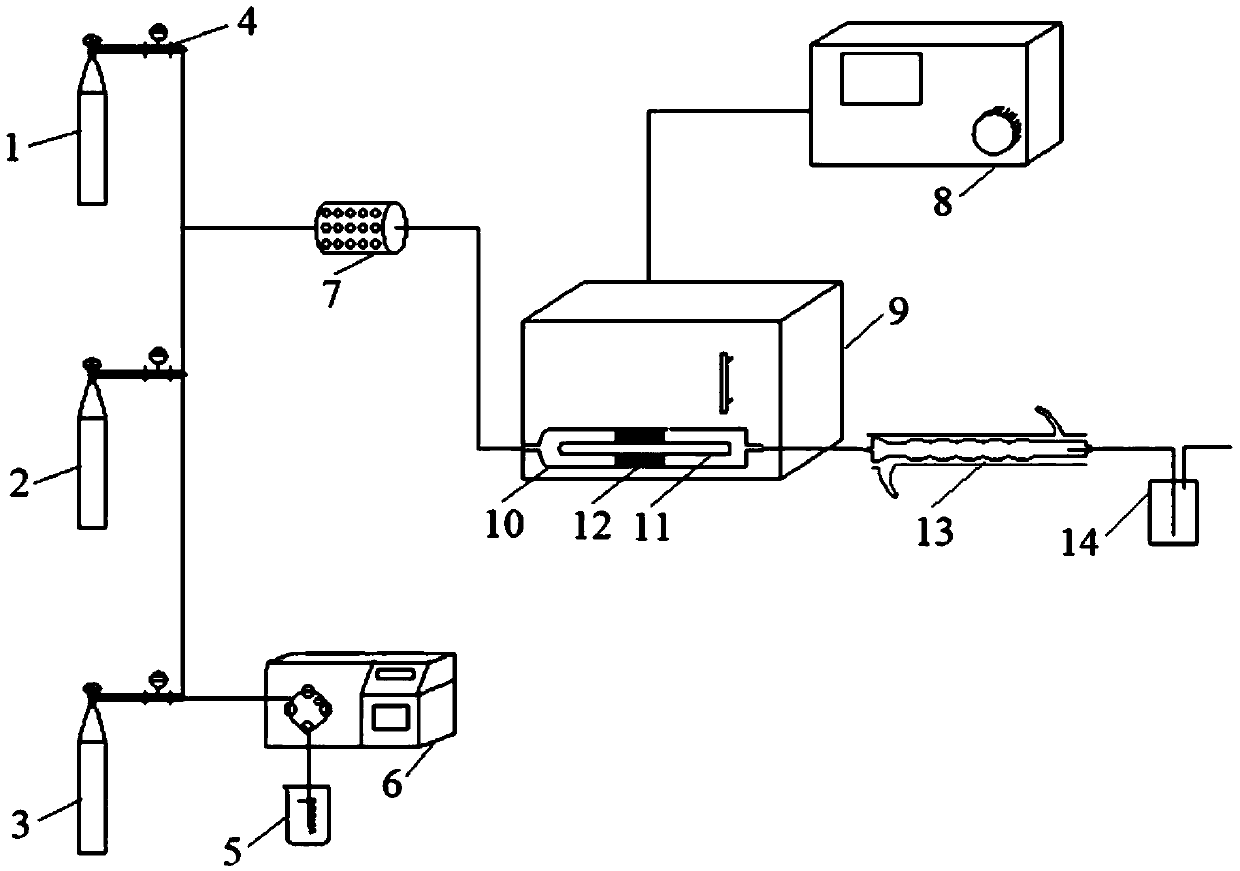

[0104] use figure 1 The system shown performs the degradation of toluene gas;

[0105] N in the first cylinder 2 and O in the second cylinder 2 Concentrations are greater than 99%, the concentration of toluene standard gas in the third cylinder is 200ppm, set N 2 The flow rate is 200ml / min, O 2 The flow rate of the toluene gas is 80ml / min, the flow rate of the toluene standard gas is 120ml / min, the flow rate of the water sucked by the peristaltic pump is 0.02ml / min, the temperature of the vaporization chamber is 100°C, the concentration of the prepared toluene gas is 60ppm, and the relative humidity is 95%;

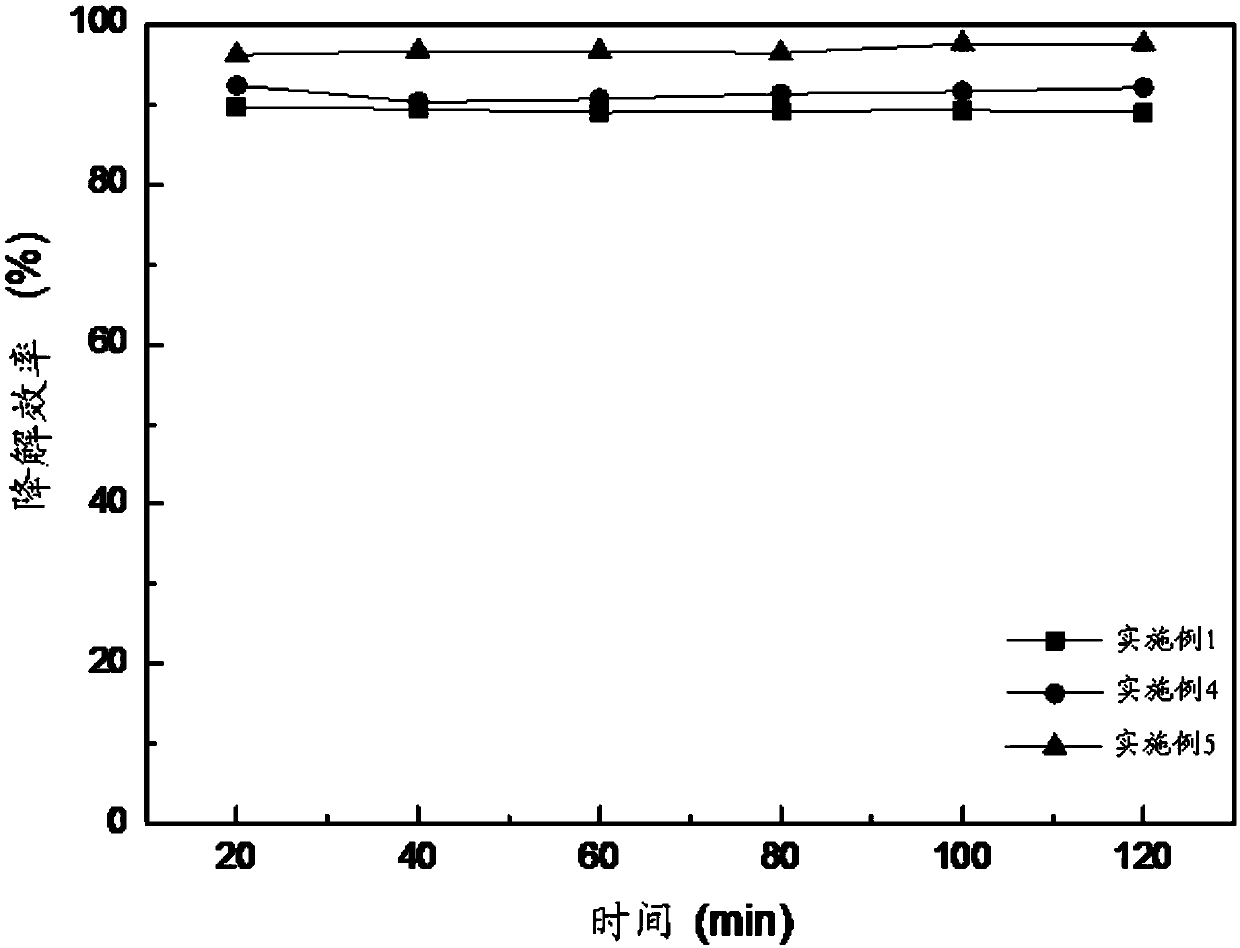

[0106] The prepared toluene gas is passed through the air inlet of the reaction chamber, the flow rate is 400ml / min, and the residence time is 30s. The catalyst in the reaction chamber is activated carbon loaded with titanium dioxide, and the consumption is 5g, wherein the content ratio of titanium dioxide to activated carbon is 0.57 : 100, adjust the AC voltage to 1...

Embodiment 2

[0111] This embodiment is similar to Embodiment 1, the difference is that the flow rate of water inhaled by the peristaltic pump is 0.01ml / min, and the relative humidity of the prepared toluene gas is 45%;

[0112] The concentration of the toluene gas that obtains after photocatalytic oxidation is 3.24ppm (, degradation efficiency is 94.6%;

[0113] The content of toluene in the condensed recovered water was 0.239mg / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com