A kind of composite phase change material and its preparation method and application

A composite phase change material and reactor technology, applied in the field of materials, can solve the problems of high manufacturing cost and technical difficulty, difficult to precisely control the amount of addition, restrict the application of phase change materials, etc., and achieve good heat storage and energy saving effect and phase change temperature. Appropriate, colloidal form stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

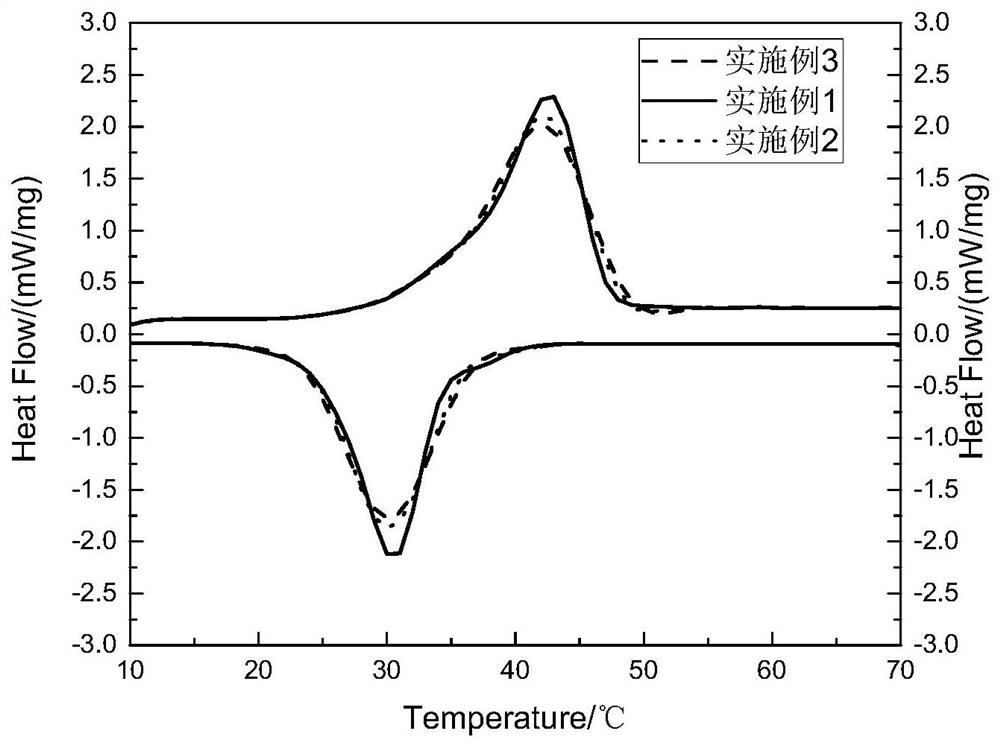

Embodiment 1

[0033] (1) Melting of capric acid: 6.0 g of capric acid was placed in a reactor and heated in a water bath at a temperature of 70° C. until completely melted;

[0034] (2) Add 14.0 g of disodium hydrogen phosphate dodecahydrate powder into the reactor after step (1), heat and stir with a constant temperature magnetic heating stirrer, set at 70° C. and continue heating and stirring for 10 minutes until the mixture is uniform;

[0035] (3) adding the carboxymethyl cellulose of 0.2 g in step (2) to the reactor of step (2) and heating and stirring;

[0036] (4) Place the sol described in step (3) in a constant temperature drying oven at 30°C to age for 24 hours to form a gel;

[0037] (5) Place the gel described in step (4) in a programmable high and low temperature alternating box for 300 cycles of heating and cooling. The high temperature of the programmed high and low temperature alternating box is set to 70°C for 30 minutes; Set it to 10°C, and the duration is 10 minutes; the...

Embodiment 2

[0040] (1) Melting of capric acid: 4.0 g of capric acid was placed in a reactor and heated in a water bath at a temperature of 75° C. until completely melted;

[0041] (2) Add 16.0 g of disodium hydrogen phosphate dodecahydrate powder into the reactor of step (1), heat and stir with a constant temperature magnetic heating stirrer, set at 65° C. and continue heating and stirring for 8 minutes until the mixture is uniform;

[0042] (3) Add 0.1 g of soluble starch, 0.1 g of sodium polyacrylate and 0.1 g of carboxymethyl cellulose mixture in step (2) into the reactor of step (2) and heat and stir;

[0043] (4) Place the sol described in step (3) in a constant temperature drying oven at 35°C to age for 24 hours to form a gel;

[0044] (5) Place the gel described in step (4) in a programmable high and low temperature alternating box for 350 cycles of heating and cooling. The high temperature of the programmed high and low temperature alternating box is set at 65°C for 35 minutes; S...

Embodiment 3

[0047] (1) Melting of capric acid: 8.0 g of capric acid was placed in a reactor and heated in a water bath at a temperature of 65° C. until completely melted;

[0048] (2) Add 12.0 g of disodium hydrogen phosphate dodecahydrate powder into the reactor after step (1), heat and stir with a constant temperature magnetic heating stirrer, set at 75° C. and continue heating and stirring for 5 minutes until the mixture is uniform;

[0049] (3) Add 0.03g soluble starch and 0.07g sodium polyacrylate into the reactor of step (2) and heat and stir in step (2);

[0050](4) Place the sol described in step (3) in a constant temperature drying oven at 25°C to age for 24 hours to form a gel;

[0051] (5) Place the gel described in step (4) in a programmable high and low temperature alternating box for 320 cycles of heating and cooling. The high temperature of the programmed high and low temperature alternating box is set at 72°C for 34 minutes; Set at 13°C, the duration is 113 minutes; a tot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition enthalpy | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com