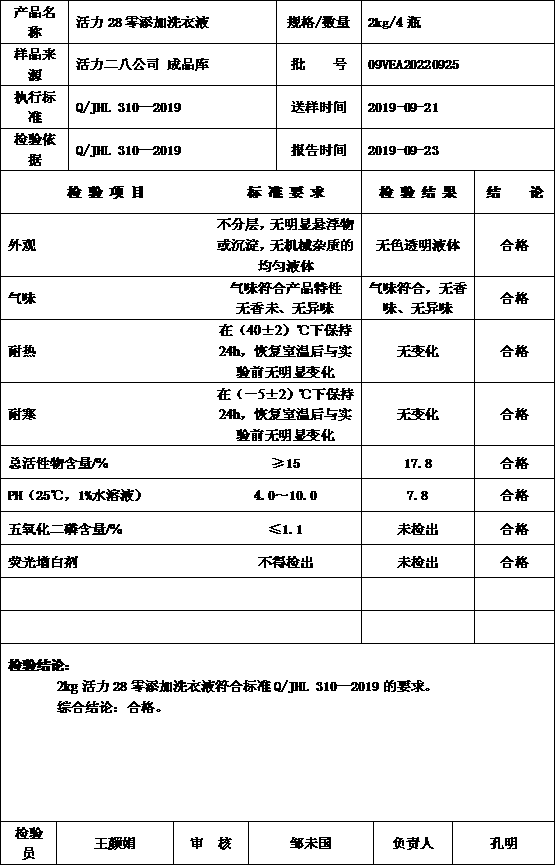

Detergent free of harmful substances or substances irritant to skin

A harmful, zero-added technology, applied in the field of detergents with zero-added harmful substances or irritating substances to the skin, can solve the problems of easy residual clothes, insoluble in water, and precipitates, etc., to improve detergency, remove Oil pollution, super penetration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] The units of measurement of each component are parts by weight in the embodiments:

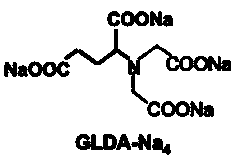

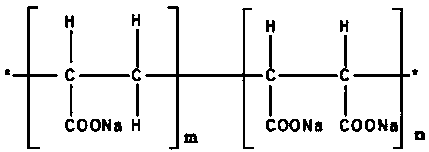

[0053] Sodium lauroyl sarcosinate: 6, Alkyl glucoside: 4, Sodium fatty acid methyl ester sulfonate: 5, Gubert alkanol polyoxyethylene ether: 5, Fatty alcohol alkoxylate: 6, Methyl-oleamide Ammonium ethyl-oleyl-imidazoline methyl sulfate: 1, sodium polyacrylate: 0.2, tetrasodium glutamate diacetate: 0.4, 2-methyl-4-isothiazolin-3-one: 0.05, 5 -Chloro-2-methyl-4-isothiazolin-3-one: 0.007, the balance is deionized water, and the total mass parts is 100 parts. The detergent is prepared by adopting the prior art process to add zero harmful substances or irritating substances to the skin.

Embodiment 2

[0055] The measurement units of each component in the examples are parts by weight.

[0056] Sodium lauroyl sarcosinate: 8, Alkyl glucoside: 2, Sodium fatty acid methyl ester sulfonate: 3, Gubert alkanol polyoxyethylene ether: 7, Fatty alcohol alkoxylate: 4, Methyl-oleamide Ammonium ethyl-oleyl-imidazoline methyl sulfate: 3, sodium polyacrylate: 0.3, tetrasodium glutamate diacetate: 0.3, 2-methyl-4-isothiazolin-3-one: 0.055, 5 -Chloro-2-methyl-4-isothiazolin-3-one: 0.006, the balance is deionized water, and the total mass parts is 100 parts. The detergent is prepared by adopting the prior art process to add zero harmful substances or irritating substances to the skin.

Embodiment 3

[0058] The measurement units of each component in the examples are parts by weight.

[0059] Sodium lauroyl sarcosinate: 7, Alkyl glucoside: 3, Sodium fatty acid methyl ester sulfonate: 4, Gubert alkanol polyoxyethylene ether: 6, Fatty alcohol alkoxylate: 5, Methyl-oleamide Ammonium ethyl-oleyl-imidazoline methyl sulfate: 2, sodium polyacrylate: 0.25, tetrasodium glutamate diacetate: 0.2, 2-methyl-4-isothiazolin-3-one: 0.06, 5 -Chloro-2-methyl-4-isothiazolin-3-one: 0.008, the balance is deionized water, and the total mass fraction is 100 parts. The detergent is prepared by adopting the prior art process to add zero harmful substances or irritating substances to the skin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com