Quenching system and method of automobile accessory

A technology of quenching system and auto parts, which is applied in the field of quenching system of auto parts, which can solve the problems that it is difficult to obtain a uniform and suitable quenching layer for connecting rods, and affect the physical properties of finished connecting rods, so as to ensure the balance of temperature and reduce the loss of heat , Improve the effect of physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

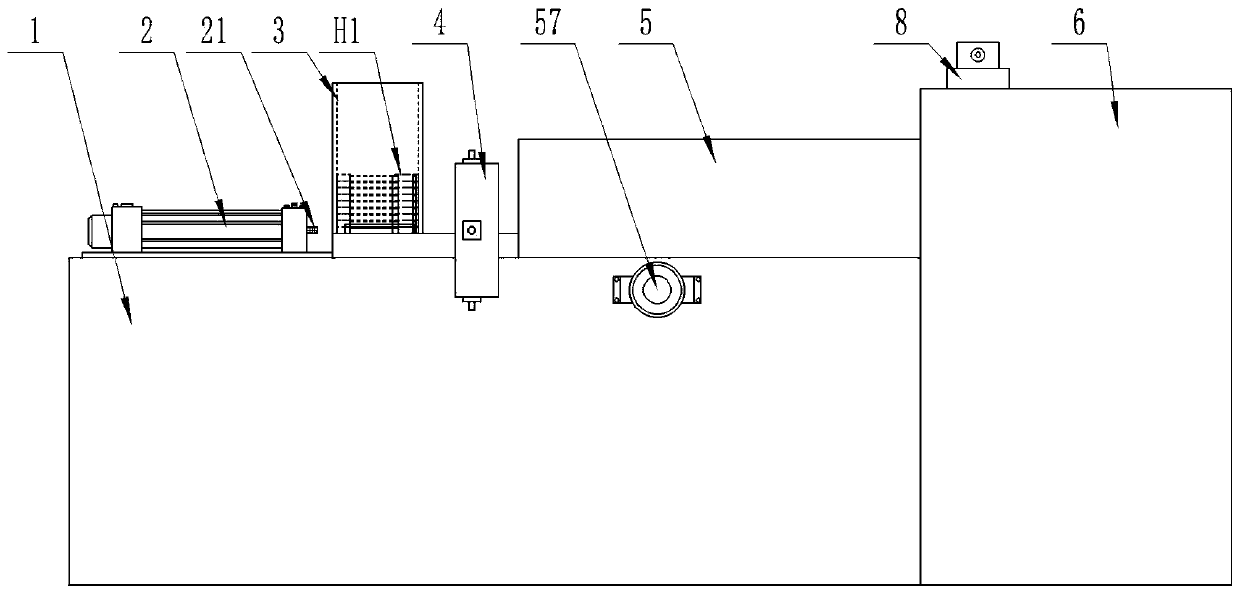

[0063] A quenching system for auto parts, wherein, such as figure 1 As shown, it includes: a base 1, a telescopic mechanism 2, a drop hopper 3, a flame heating mechanism 4, a thermal insulation transmission mechanism 5, and a quenching box 6.

[0064] The telescopic mechanism 2 is installed on the left side of the base 1 , and the right side of the telescopic mechanism 2 has a telescopic end 21 .

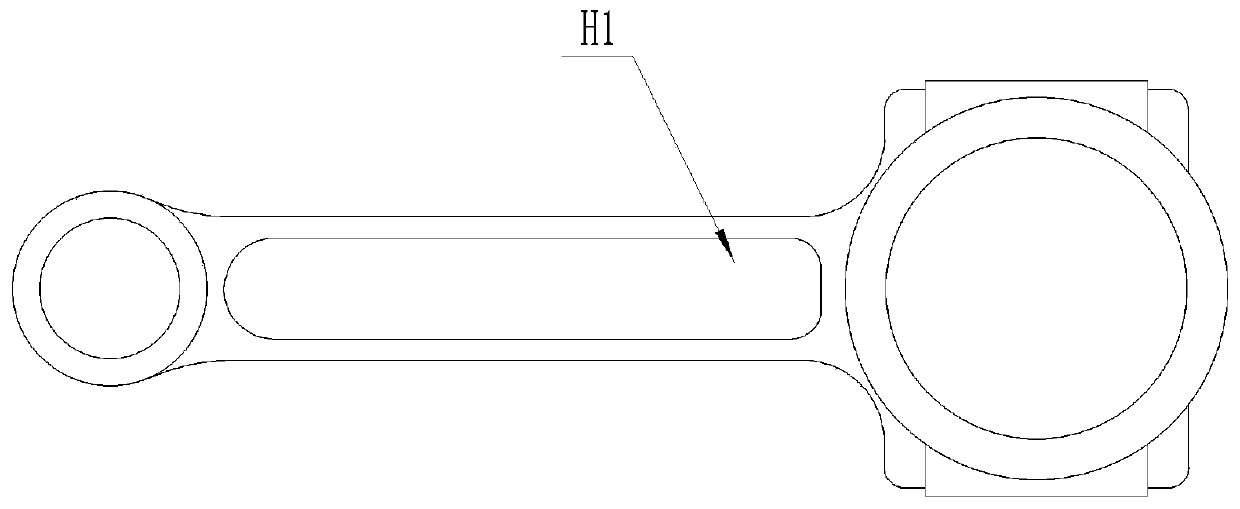

[0065] The blanking hopper 3 is installed on the base 1, and the blanking hopper 3 is located on the right side of the telescopic mechanism 2. The bottom of the blanking hopper 3 has a through opening (not shown), and the through opening runs through the left and right sides of the bottom of the blanking hopper 3. The through opening and the telescopic end 21 Correspondingly, the shape and size of the through opening and the connecting rod H1 are adapted to each other.

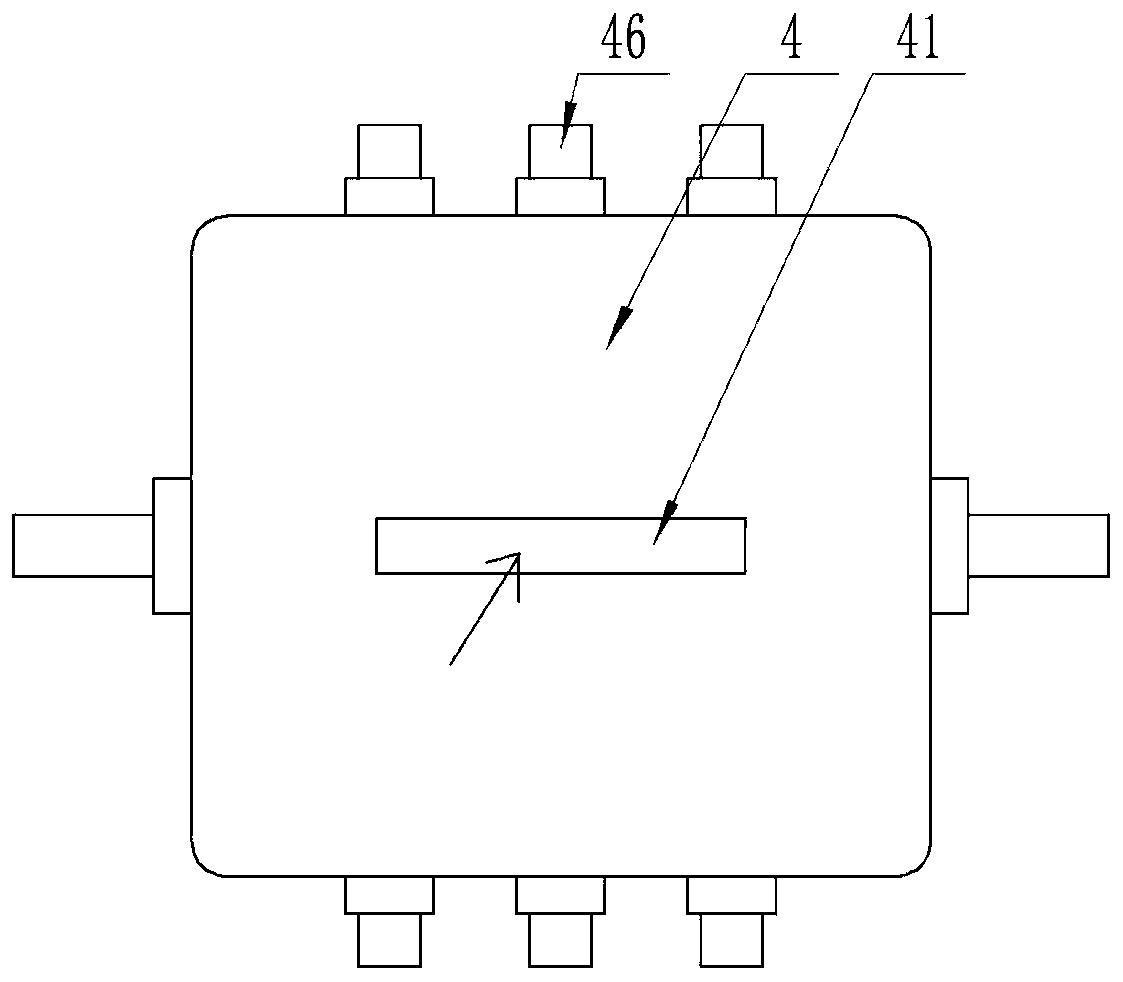

[0066] Such as figure 1 , 3 , 4, and 6, the fire-spraying heating mechanism 4 is installed on the base 1, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com