Method for preparing high-hydrophobicity film by electrostatic spinning

A hydrophobic film and electrospinning technology, which is applied in the fields of filament/thread forming, textile and papermaking, medical science, etc., can solve the problems of unsatisfactory antibacterial performance and general hydrophobic performance, and achieve strong antibacterial adhesion ability , improve antibacterial ability, hydrophobic performance better effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the content of the present invention easier to understand, the technical solutions of the present invention will be further described below in conjunction with specific embodiments, but the present invention is not limited thereto.

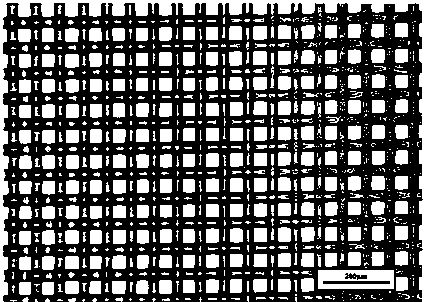

[0037] The mesh template used was a nylon mesh with a pore size of 20-200 μm, which was purchased from sigma company.

[0038] A method for electrospinning to prepare a strong hydrophobic membrane, comprising the following steps:

[0039] (1) Dissolving a biocompatible hydrophobic polymer in a solvent and stirring until the solution is completely dissolved to prepare a hydrophobic polymer solution;

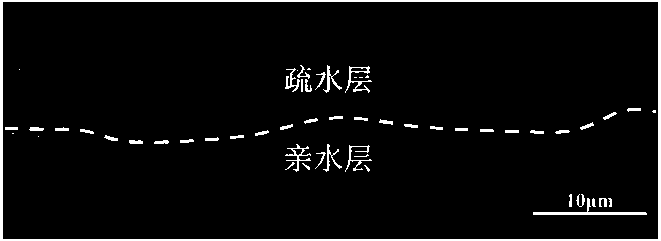

[0040] (2) Fix a detachable mesh template with a pore size of 20-200 microns on the surface of the receiver of the electrospinning machine, and then spray the hydrophobic polymer solution prepared in step (1) onto the mesh through the electrospinning machine on the surface of the template, thereby depositing a hydrophobic fibe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com