Hydrophobic moisture-absorbing fabric coating and preparation method thereof

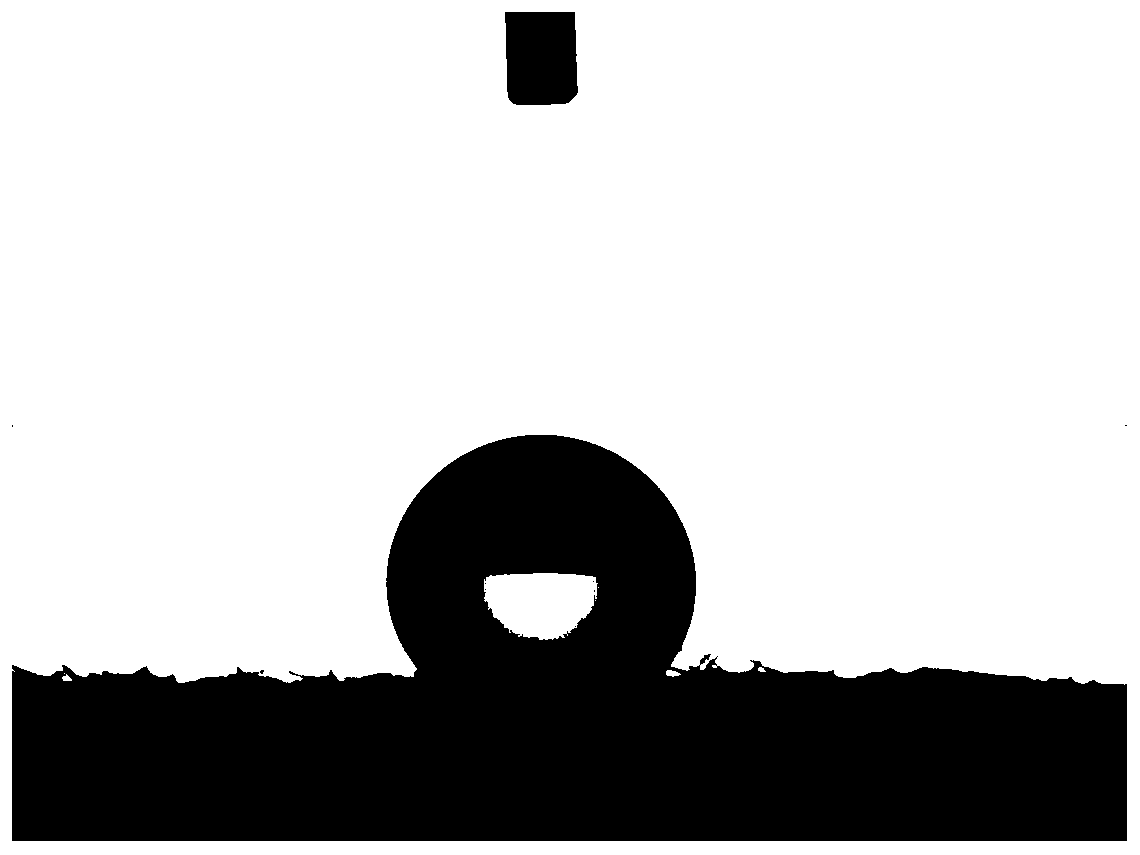

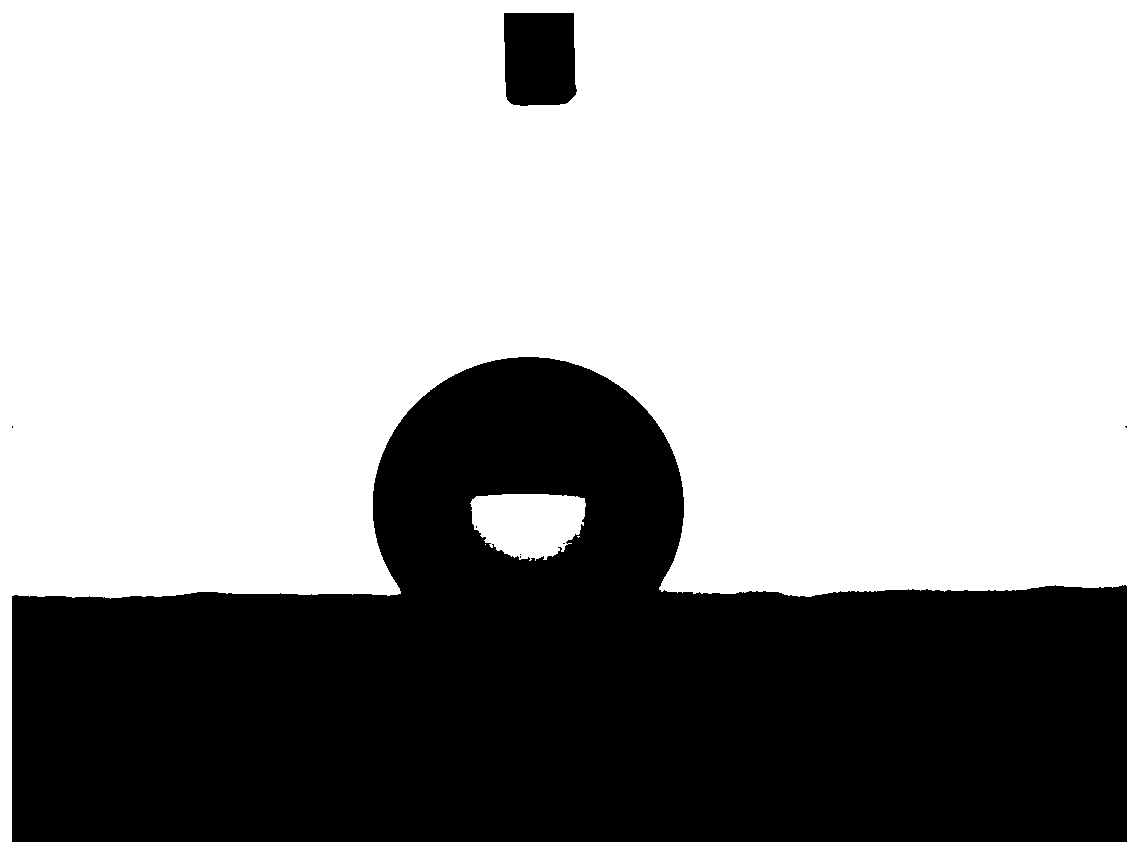

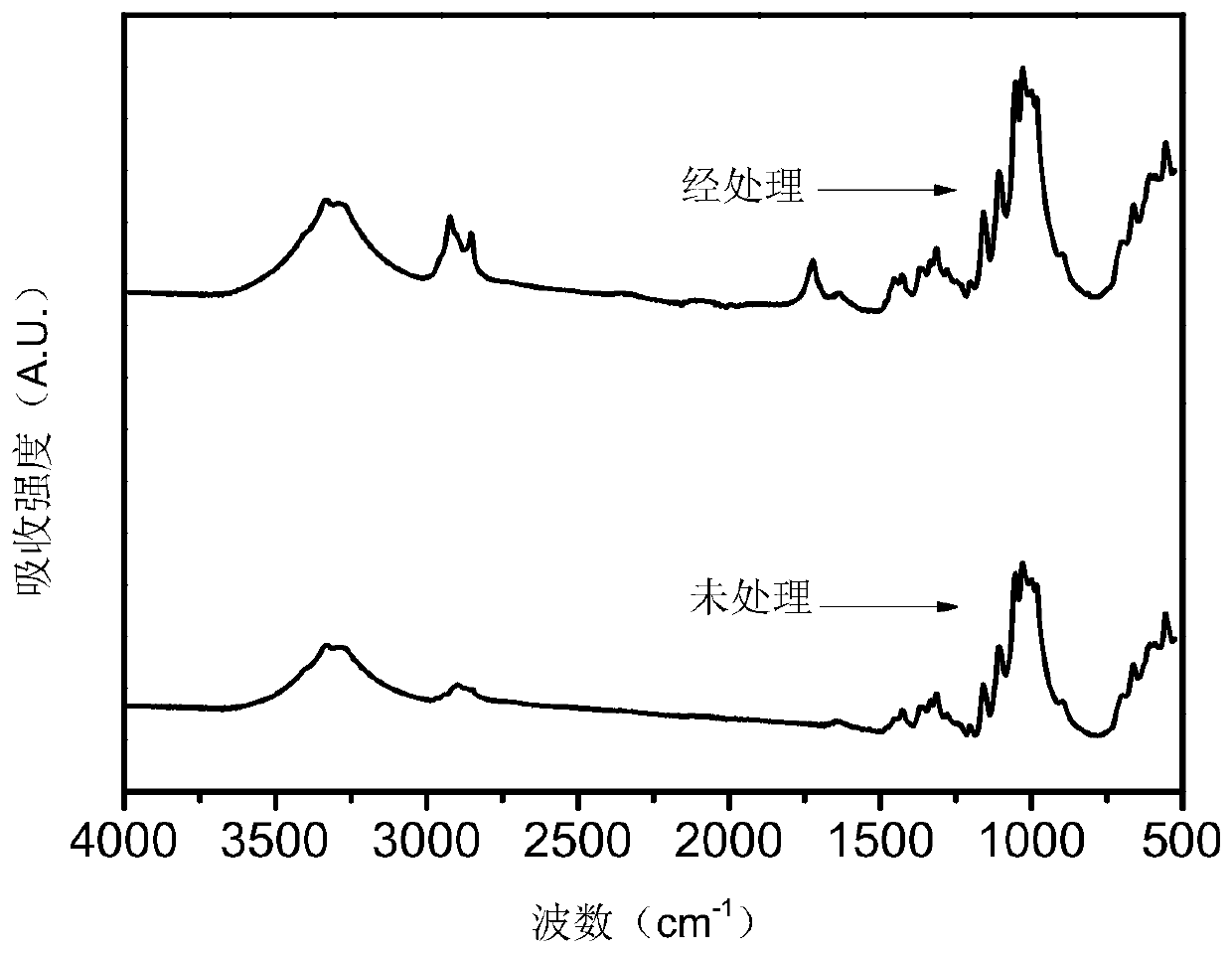

A fabric and coating technology, which is applied in the field of hydrophobic and hygroscopic fabric coatings and its preparation, can solve the problem that hydrophobic and hygroscopic fabrics cannot have good hydrophobic and hygroscopic properties at the same time, achieve excellent hydrophobic and hygroscopic properties, and form less pollutants. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A kind of preparation method of hydrophobic hygroscopic fabric coating, its specific steps are as follows:

[0045] (1) Mix methacrylic acid (hydrophilic monomer 2), tetradecyl methacrylate (hydrophobic monomer 1), polyethylene glycol diacrylate (crosslinking agent 3) and 1-hydroxycyclohexylbenzophenone Mix to obtain a mixed solution; Wherein, the mass ratio of polyethylene glycol diacrylate and methacrylic acid is 1:1, and the quality of 1-hydroxycyclohexylbenzophenone is methacrylic acid and tetradecyl methacrylate total mass 1.5%, the mass of tetradecyl methacrylate accounts for 75% of the total mass of methacrylic acid, tetradecyl methacrylate and polyethylene glycol diacrylate;

[0046] (2) Dilute mixed solution with acetone to obtain coating solution; Wherein, the volume ratio of acetone and mixed solution is 1.5:1;

[0047] (3) putting the cotton fabric into the coating solution for dip coating and then putting it into a roll machine for extrusion; wherein, the ...

Embodiment 2

[0056] A kind of preparation method of hydrophobic hygroscopic fabric coating, its specific steps are as follows:

[0057] (1) Mix methacryloyl ethyl sulfobetaine, cetyl acrylate, polyethylene glycol diacrylate and benzophenone to obtain a mixed solution; wherein, polyethylene glycol diacrylate and methacrylic acid The mass ratio of acylethyl sultaine is 1:5, the quality of benzophenone is 1% of the total mass of methacryloyl ethyl sultaine and cetyl acrylate, and the mass of cetyl acrylate Accounting for 70% of the total mass of methacryloyl ethyl sulfobetaine, cetyl acrylate and polyethylene glycol diacrylate;

[0058] (2) Dilute the mixed solution with dimethylamide to obtain a coating solution; wherein, the volume ratio of dimethylamide to the mixed solution is 0.5:1;

[0059] (3) putting the polyester fabric into the coating solution for dip coating and then putting it into a roller machine for extrusion; wherein, the extrusion pressure is 0.3MPa;

[0060] (4) Drying af...

Embodiment 3

[0065] A kind of preparation method of hydrophobic hygroscopic fabric coating, its concrete steps are as follows:,

[0066] (1) Mix acrylamide, octadecyl acrylate, N-carboxyethylacrylamide and 2,4,6-trimethylbenzoyldiphenoxyphos to obtain a mixed solution; wherein, N-carboxyethylacrylamide The mass ratio with acrylamide is 1:15, the quality of 2,4,6-trimethylbenzoyl diphenoxyphosphine is 0.5% of the total mass of acrylamide and stearyl acrylate, and the mass of stearyl acrylate accounts for The percentage of the total mass of acrylamide, octadecyl acrylate and N-carboxyethyl acrylamide is 70%;

[0067] (2) Dilute mixed solution with acetone to obtain coating solution; Wherein, the volume ratio of acetone and mixed solution is 4.5:1;

[0068] (3) putting the cotton fabric into the coating solution for dip coating and then putting it into a roll machine for extrusion; wherein, the extrusion pressure is 0.1MPa;

[0069] (4) Drying after irradiating the fabric with ultraviolet l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com