Method and system for using waste heat to supply hydrogen to hcng engine power system

A power system and engine technology, which is applied in the direction of engine components, combustion engines, machines/engines, etc., can solve the problems of unguaranteed safety performance, large volume of hydrogen source system, and low volume density of hydrogen storage, so as to achieve efficient, accurate and stable hydrogen supply , Increase the combustion efficiency, reduce the effect of pollution emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0032] The present invention proposes a method and system for utilizing waste heat to efficiently and accurately supply hydrogen to an HCNG engine power system, which has the advantages of high comprehensive thermal efficiency, less emissions, stable and precisely controllable hydrogen supply, small volume of required hydrogen source system, and good safety performance Etc.

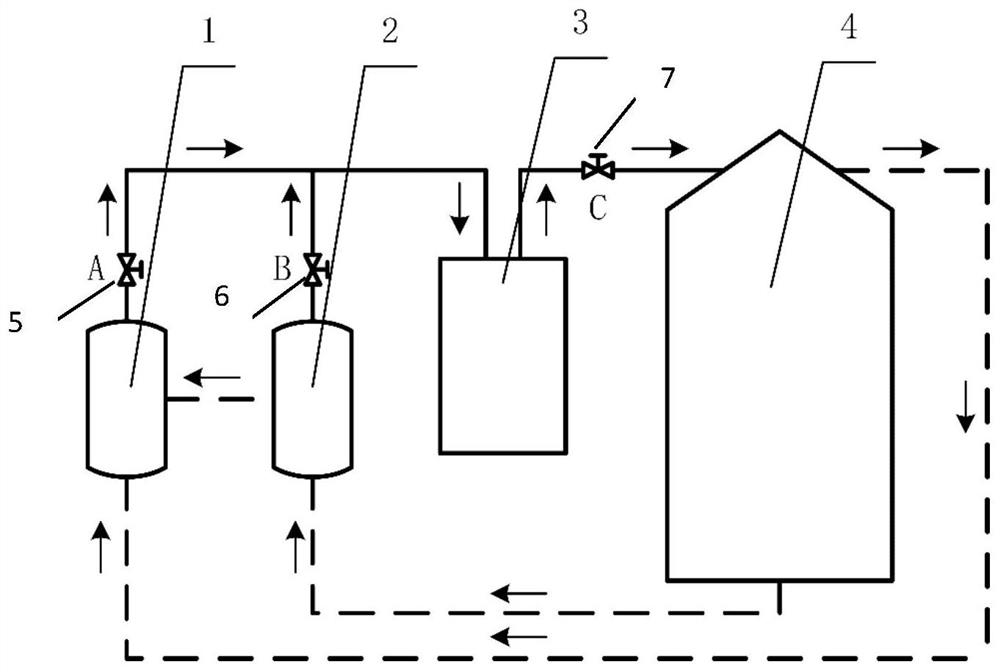

[0033] see figure 1 , a system that uses waste heat to efficiently and accurately supply hydrogen to the HCNG engine power system, including a medium-high temperature solid metal hydride hydrogen storage reactor 1, a low-temperature solid metal hydride hydrogen storage reactor 2, a fuel mixing chamber 3 and SI (spark plug ignition type) engine 4.

[0034] A first valve 5 and a second valve 6 are provided at the outlets of the medium-high temperature solid metal hydride hydrogen storage reactor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com