Servo valve and servo unit integrated with digital shaft controller

An axis controller and servo valve technology, applied in servo motors, servo motor components, fluid pressure actuation devices, etc., can solve various problems such as complex parameter matching, inability to high precision, and complex speed regulation, to meet the needs of the Internet of Things. Communication control requirements, high oil pollution resistance, and high control integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

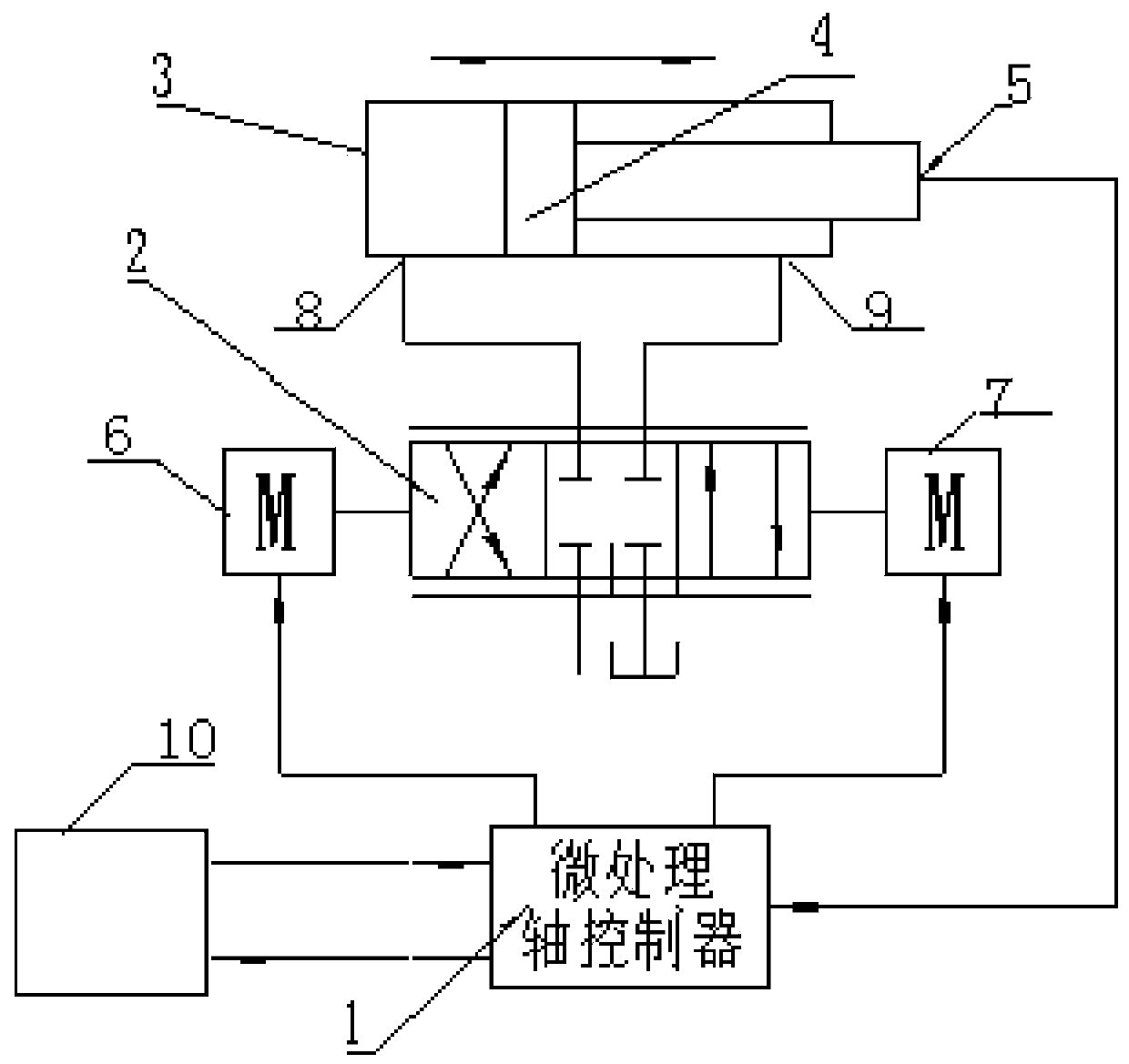

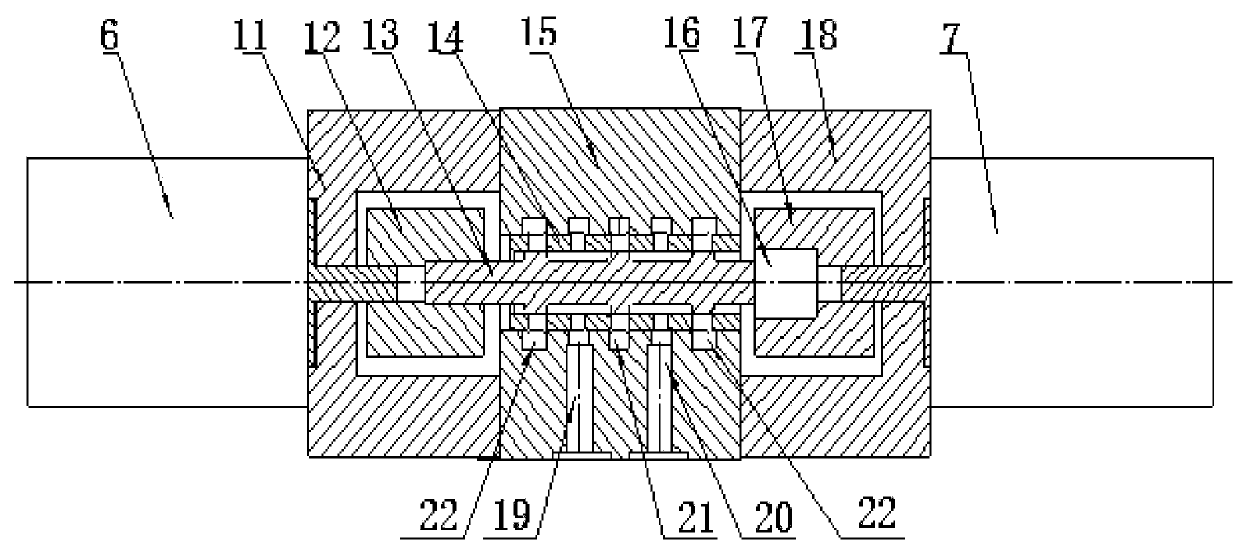

[0030] Such as figure 1 As shown, a servo valve and a servo unit integrating a digital axis controller according to an embodiment of the present invention include a microprocessor axis controller 1, a servo valve body 2, a servo control element, and a first driving connection with both ends of the servo valve body 2. The drive motor 6 and the second drive motor 7, the micro-processing axis controller 1 communicates with the remote control terminal 10, the micro-processing axis controller 1 communicates with the control end of the drive motor 6 and the second drive motor 7, and the first drive The motor 6 is a digital drive motor, and the second drive motor 7 is a digital drive motor. The servo valve body 2 is provided with a high pressure oil chamber 21, an oil return chamber 22, an oil outlet chamber 19 communicated with the oil inlet 8 of the servo control element and The oil return chamber 20 communicated with the oil return port 9 of the servo control element, the high pre...

Embodiment 2

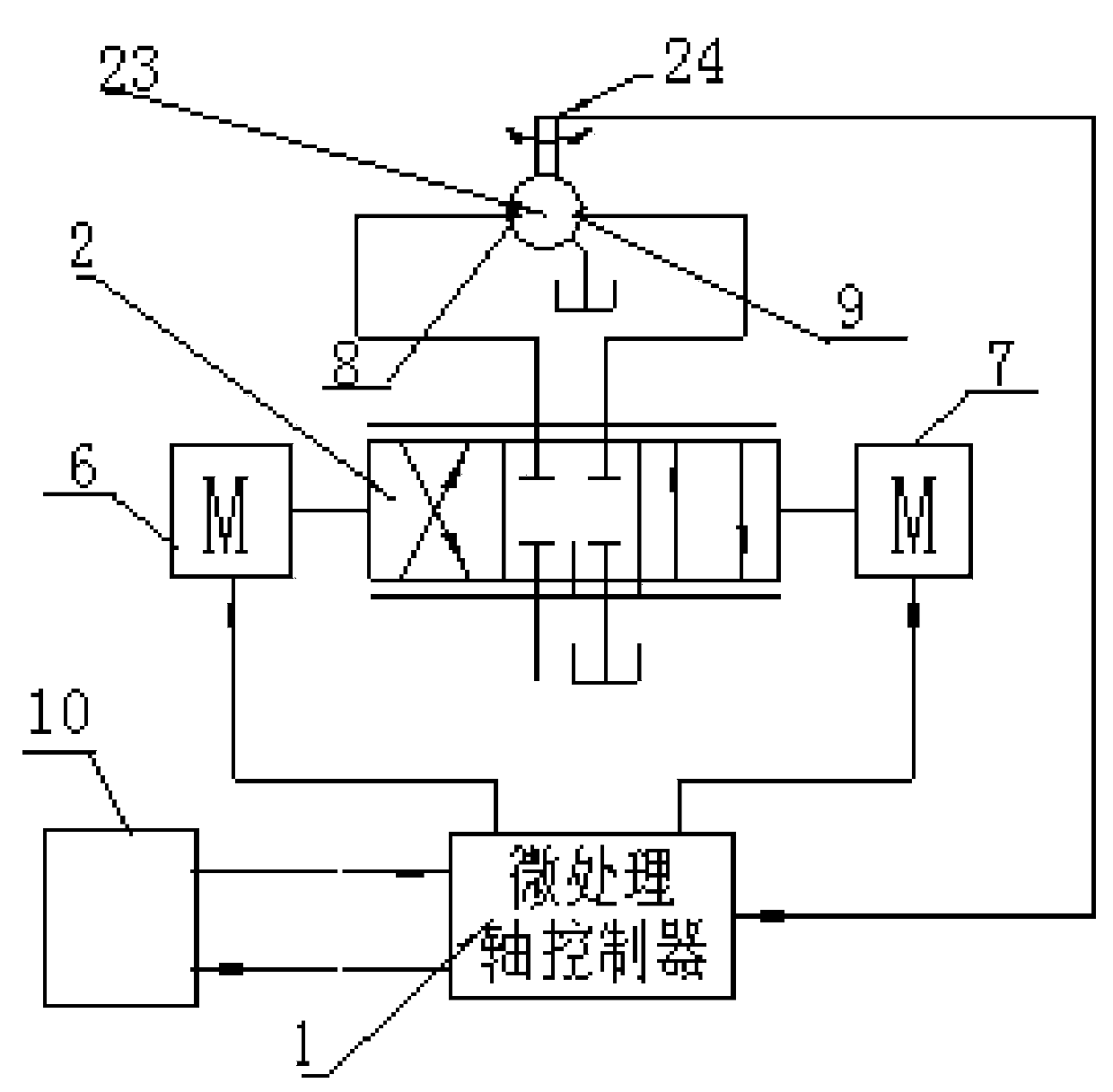

[0037] The servo valve and servo unit of the integrated digital axis controller are also suitable for motor servo. The principle is the same as that of the oil cylinder control, which can realize precise control of the speed and rotation angle of the motor.

[0038] The rest are all the same as in Embodiment 1, and the servo control element is replaced by a hydraulic motor 23 .

[0039] Such as image 3 As shown, the servo control element includes a hydraulic motor 23 , and a feedback sensor is provided on the hydraulic motor 23 , and the feedback sensor communicates with the microprocessor axis controller 1 .

[0040] The feedback sensor is a motor rotation angle sensor 24 .

[0041] The microprocessor axis controller 1 adopts a high-speed digital microprocessor to receive the control command signal (such as the motor target rotation angle command signal) from the remote control terminal 10. The control signal can be high-speed digital communication, and the communication in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com