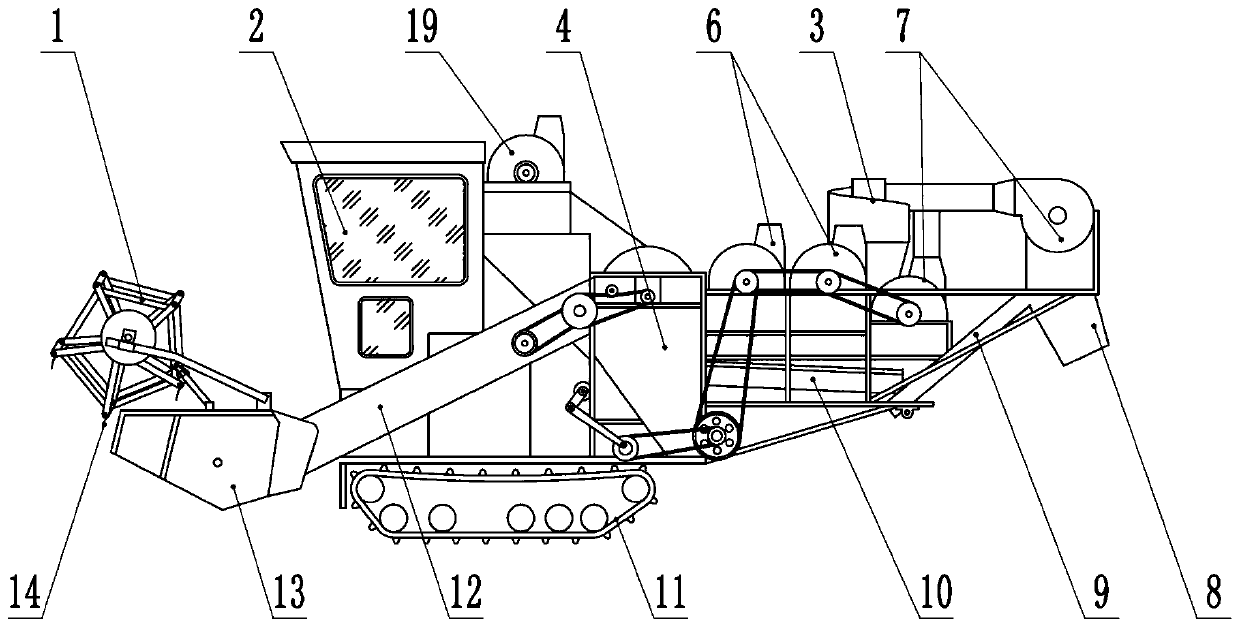

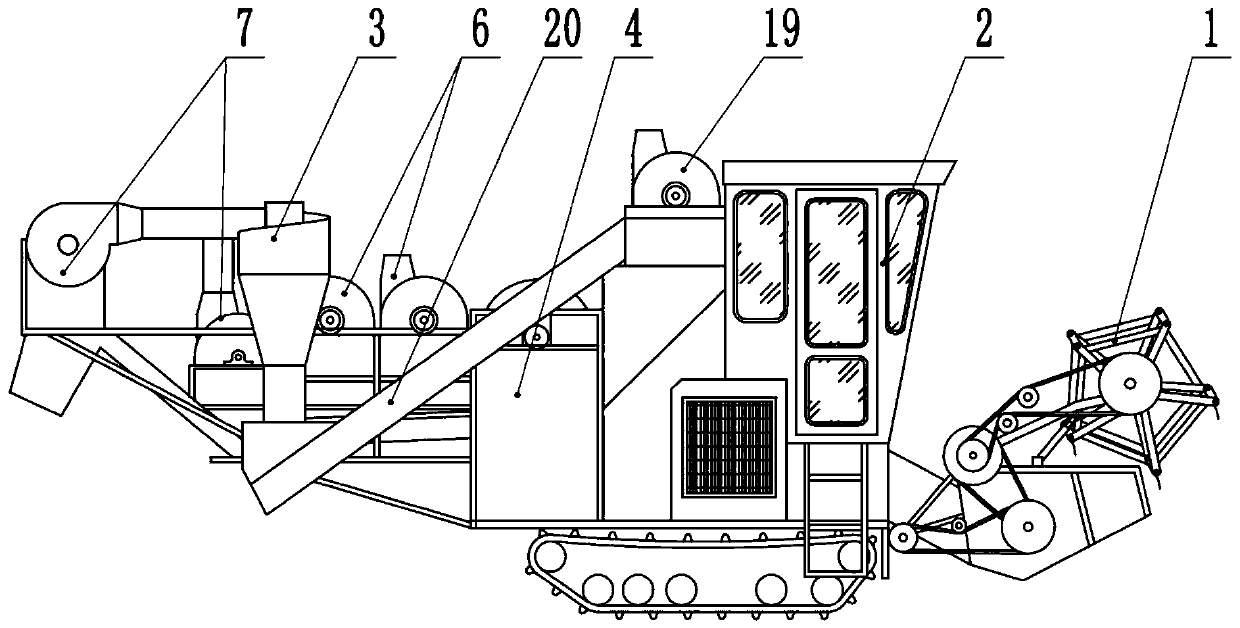

Tracked peanut seedling film removing and rolling-cutting combine machine

A peanut seedling and crawler-type technology, which is applied in the field of crawler-type peanut seedling combined film removal kneading and cutting machine, can solve the problems of cumbersomeness, small working space, and low work efficiency, and achieve high degree of automation, small turning radius, and high work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

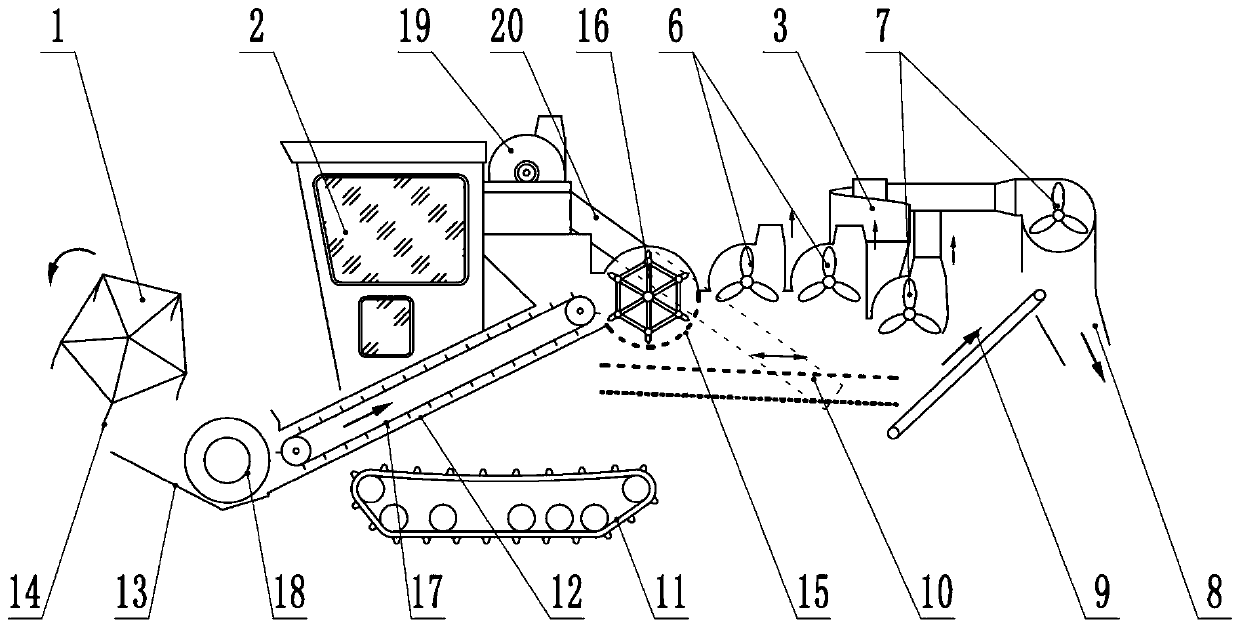

Embodiment 2

[0032] The feeding device described in Embodiment 2 is the feeding conveyor belt 20 . The vibrating screen 10 has a two-layer structure, with large holes in the upper layer and small holes in the lower layer. Bulk peanut seedlings are left on the vibrating screen 10 upper floors, and small pieces of peanut seedlings fall on the vibrating screen 10 lower floors. The discharge conveyor belt 9 is located below the rear end of the lower layer of the fuselage 10, and the qualified crushed peanut seedlings after the lower layer of the vibrating screen 10 fall on the discharge conveyor belt 9 to be output. The return conveyor belt 20 is located on one side of the fuselage 4 , the head end of the return conveyor belt 20 is located at the vibrating screen 10 , and the end of the return conveyor belt 20 is located above the front end of the fuselage 4 . The two ends of the return conveyor belt 20 are respectively provided with a material conveying device, and the material conveying dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com