Ultra-thin soft magnetic ferrite magnetic core preparation process

A soft ferrite and preparation process technology, applied in inductor/transformer/magnet manufacturing, manufacturing tools, magnetic objects, etc., can solve the problems of low production yield and complex cross-sectional shape, and achieve the effect of improving structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

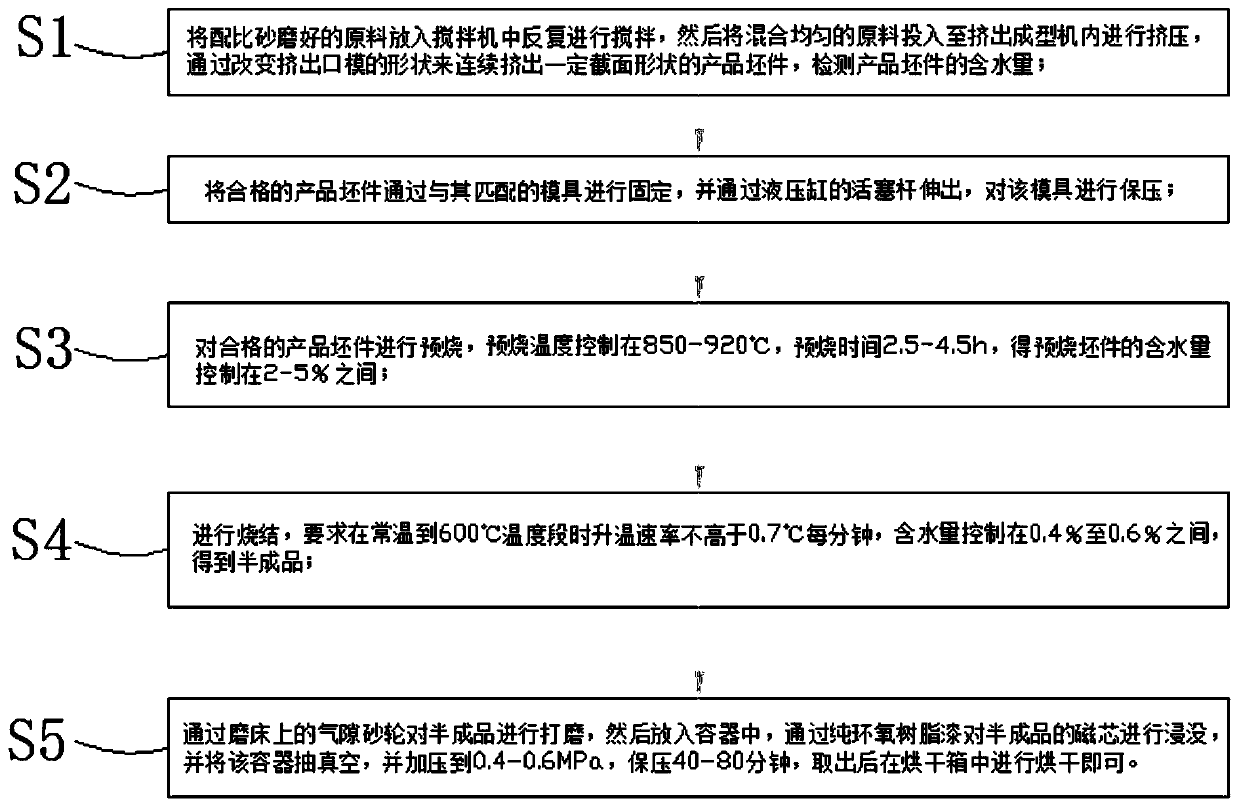

[0019] The invention provides a preparation process of an ultra-thin soft ferrite core, comprising the following steps:

[0020] S1: Put the raw materials that have been sanded in proportion into the mixer for repeated stirring, then put the evenly mixed raw materials into the extrusion molding machine for extrusion, and continuously extrude a certain cross-sectional shape by changing the shape of the extrusion die Product blanks, testing the moisture content of product blanks;

[0021] S2: Fix the qualified product blank through the matching mold, and stretch out the piston rod of the hydraulic cylinder to maintain the pressure on the mold;

[0022] S3: Pre-burning qualified product blanks, the pre-burning temperature is controlled at 850-920°C, and the pre-burning time is 2.5-4.5h, so that the moisture content of the pre-fired blanks is controlled between 2-5%;

[0023] S4: For sintering, it is required that the heating rate is not higher than 0.7°C per minute in the temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com