2,5-hexanedione synthesis method

A synthetic method, the technology of hexanedione, which is applied in 2 fields, can solve the problems of high cost and rare raw materials, and achieve the effects of easy acquisition, low technical cost and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

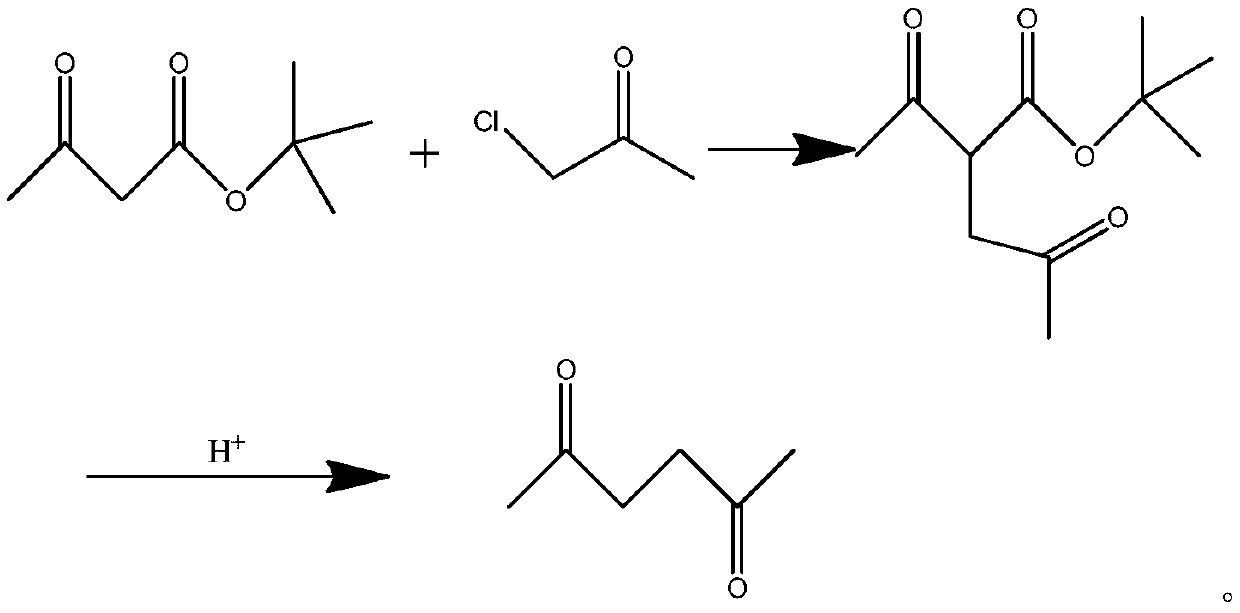

[0011] The present invention provides a kind of synthetic method of 2,5-hexanedione, adopts tert-butyl acetoacetate to react with chloroacetone under the action of alkali to generate tert-butyl 3-acetylmethylacetoacetate, then hydrolyzes under acidic condition, Deacidification gives 2,5-hexanedione,

[0012] The synthetic chemical formula of described 2,5-hexanedione is as follows:

[0013]

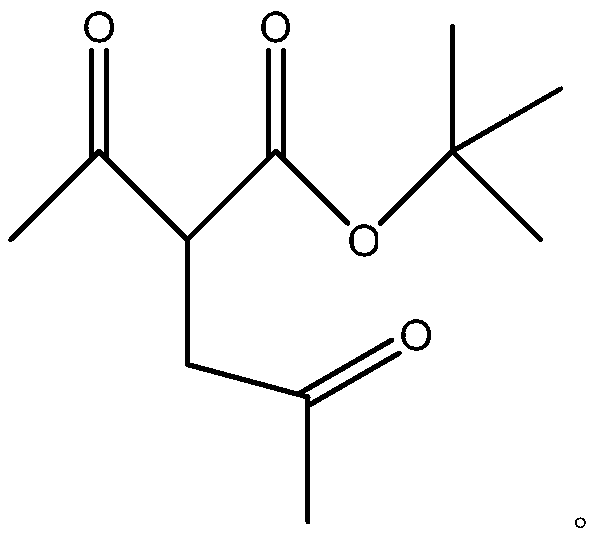

[0014] The general formula of the 2,5-hexanedione intermediate is as follows:

[0015]

[0016] Wherein, the base is selected from anhydrous carbonate, triethylamine, pyridine, and the acid is selected from sulfuric acid, hydrochloric acid, phosphoric acid and trifluoroacetic acid.

Embodiment 1

[0019] In a 2000 ml reactor, add 260 g tert-butyl acetoacetate, 145 g chloroacetone and 1000 g toluene, raise the temperature to 60-80 °C, add 150 kg triethylamine dropwise, and continue the reaction for 5 hours after the drop is complete. Cool, filter, and remove toluene to obtain 290 kg of product tert-butyl 3-acetylmethylacetoacetate with a yield of 90.6%, which is used for the next step reaction.

[0020] Add 500g of 20% sulfuric acid solution and 290g of the product from the previous step into a 1000-liter enamel reaction kettle, heat to 60-70°C for 8 hours, cool, extract with toluene, remove toluene, and distill under reduced pressure to obtain 2,5-hexanedione 138kg, the yield is 90.9%.

Embodiment 2

[0022] In a 2000ml reactor, add 260g of tert-butyl acetoacetate, 145g of chloroacetone and 1000Kg of toluene, raise the temperature to 60-80°C, add 150kg of triethylamine dropwise, continue to react for 8 hours after the addition, cool and filter. Toluene was removed to obtain 280 kg of tert-butyl 3-acetylmethylacetoacetate with a yield of 87.5%. for the next reaction.

[0023] Add 500g of 20% hydrochloric acid solution and 290g of the product from the previous step into a 1000-liter enamel reaction kettle, heat to 60-70°C for 8 hours, cool, extract with toluene, remove toluene, and distill under reduced pressure to obtain 2,5-hexanedione 135kg, the yield is 90.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com