Three dimensional PVC tablecloth and production technology thereof

A production process and technology of PVC resin powder, applied in tablecloths, other household appliances, applications, etc., can solve the problems of poor decorative effect, complex production process, lack of three-dimensionality, etc., to achieve clear and exquisite pattern texture, simple production process, Improve the effect of decorative effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

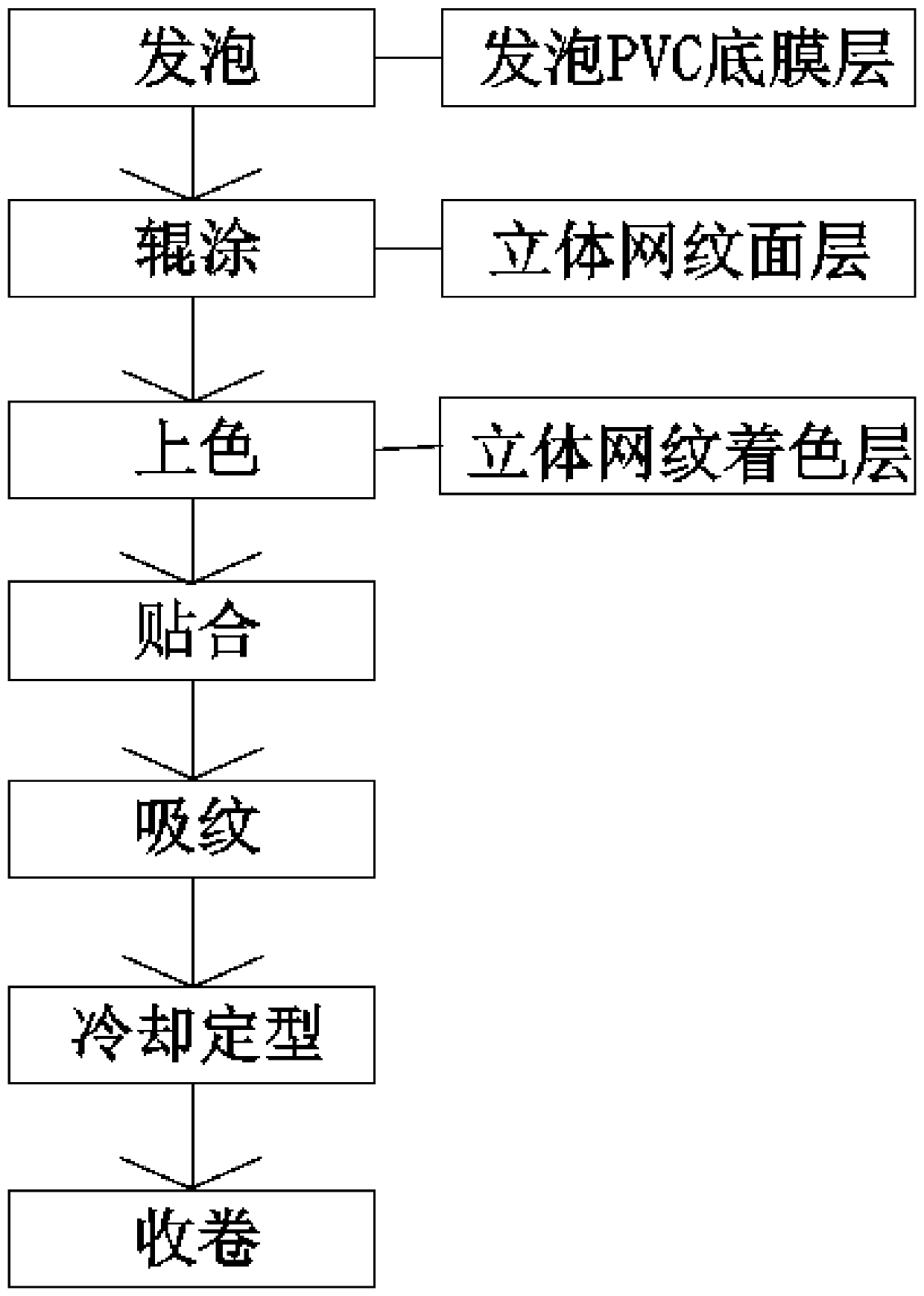

[0056] The production technology of three-dimensional PVC tablecloth comprises the following steps:

[0057] S1: Foaming, the foaming step includes batching, stirring, molding, coating and scraping to form a foamed PVC bottom film layer;

[0058] S2: Roller coating, using a 30-mesh-60-mesh nickel-chromium screen roller to roll-coat the surface of the foamed PVC surface to form a three-dimensional textured surface layer;

[0059] S3: Coloring, coloring on the surface of the three-dimensional textured surface layer to form a foamed three-dimensional textured surface coloring layer;

[0060] S4: bonding, bonding the foamed PVC bottom film layer with the three-dimensional textured surface layer and the foamed three-dimensional textured surface coloring layer, and the bonding step adopts a fusion bonding method combining direct bonding and oblique bonding;

[0061] S5: Embossing, the embossing step uses a vacuum high-pressure ceramic embossing roller to emboss the embossing;

[0...

Embodiment 2

[0067] The production technology of three-dimensional PVC tablecloth comprises the following steps:

[0068] S1: Foaming, the foaming step includes batching, stirring, molding, coating and scraping to form a foamed PVC bottom film layer;

[0069] S2: Roller coating, using a 30-mesh-60-mesh nickel-chromium screen roller to roll-coat the surface of the foamed PVC surface to form a three-dimensional textured surface layer;

[0070] S3: Coloring, coloring on the surface of the three-dimensional textured surface layer to form a foamed three-dimensional textured surface coloring layer;

[0071] S4: bonding, bonding the foamed PVC bottom film layer with the three-dimensional textured surface layer and the foamed three-dimensional textured surface coloring layer, and the bonding step adopts a fusion bonding method combining direct bonding and oblique bonding;

[0072] S5: Embossing, the embossing step uses a vacuum high-pressure ceramic embossing roller to emboss the embossing;

[0...

Embodiment 3

[0078] The production technology of three-dimensional PVC tablecloth comprises the following steps:

[0079] S1: Foaming, the foaming step includes batching, stirring, molding, coating and scraping to form a foamed PVC bottom film layer;

[0080]S2: Roller coating, using a 30-mesh-60-mesh nickel-chromium screen roller to roll-coat the surface of the foamed PVC surface to form a three-dimensional textured surface layer;

[0081] S3: Coloring, coloring on the surface of the three-dimensional textured surface layer to form a foamed three-dimensional textured surface coloring layer;

[0082] S4: bonding, bonding the foamed PVC bottom film layer with the three-dimensional textured surface layer and the foamed three-dimensional textured surface coloring layer, and the bonding step adopts a fusion bonding method combining direct bonding and oblique bonding;

[0083] S5: Embossing, the embossing step uses a vacuum high-pressure ceramic embossing roller to emboss the embossing;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com