Pyrolysis gasification equipment for treating garbage

A technology of pyrolysis gasification and equipment, which is applied in the direction of gasification process, fixed bed gasification, gasification device details, etc. It can solve the problems of high moisture content of garbage and high humidity garbage can not be processed well, etc. Achieve the effect of smooth air outlet process, simple and reliable structure, and reduce production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] Below in conjunction with each accompanying drawing, the present invention is described in detail.

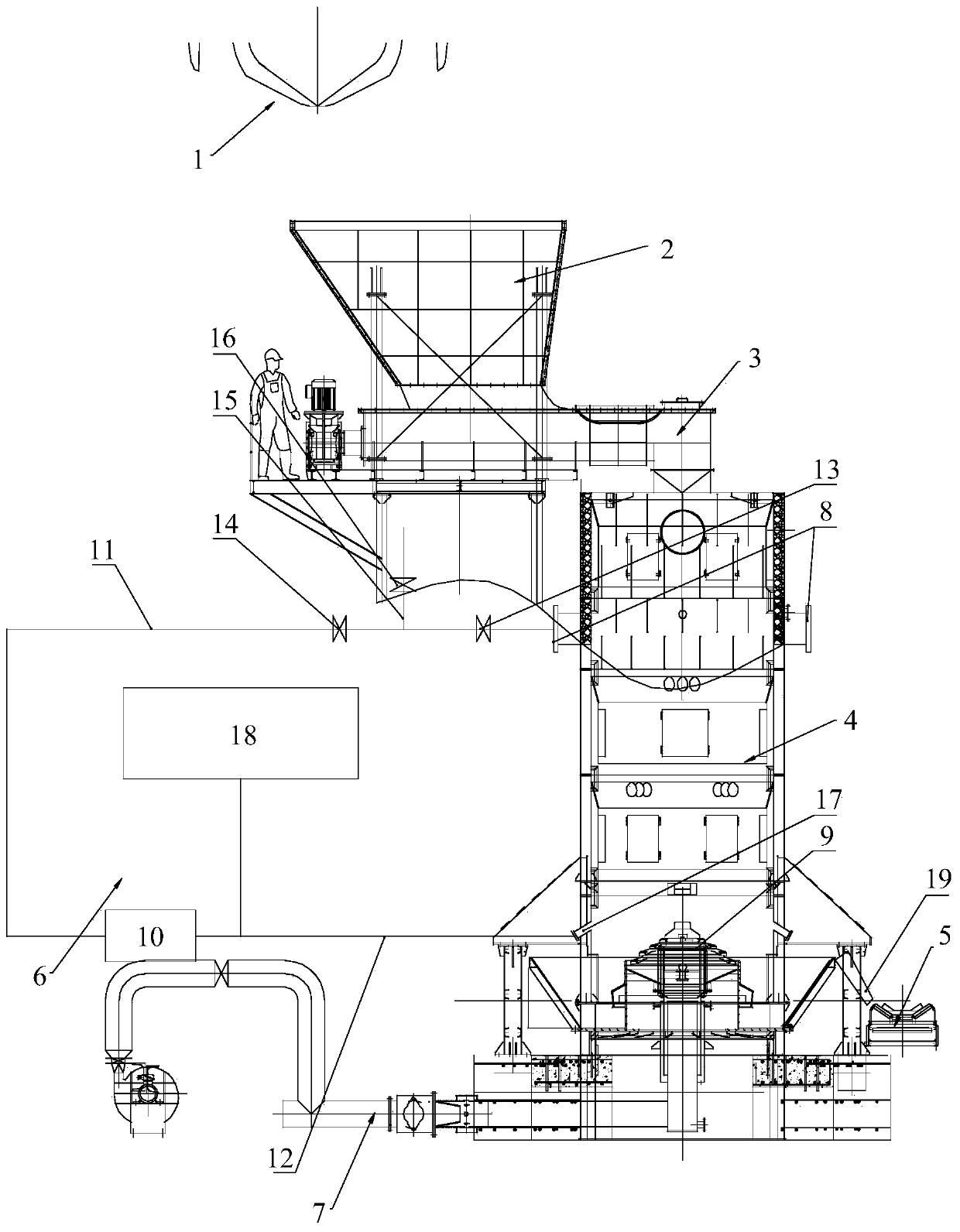

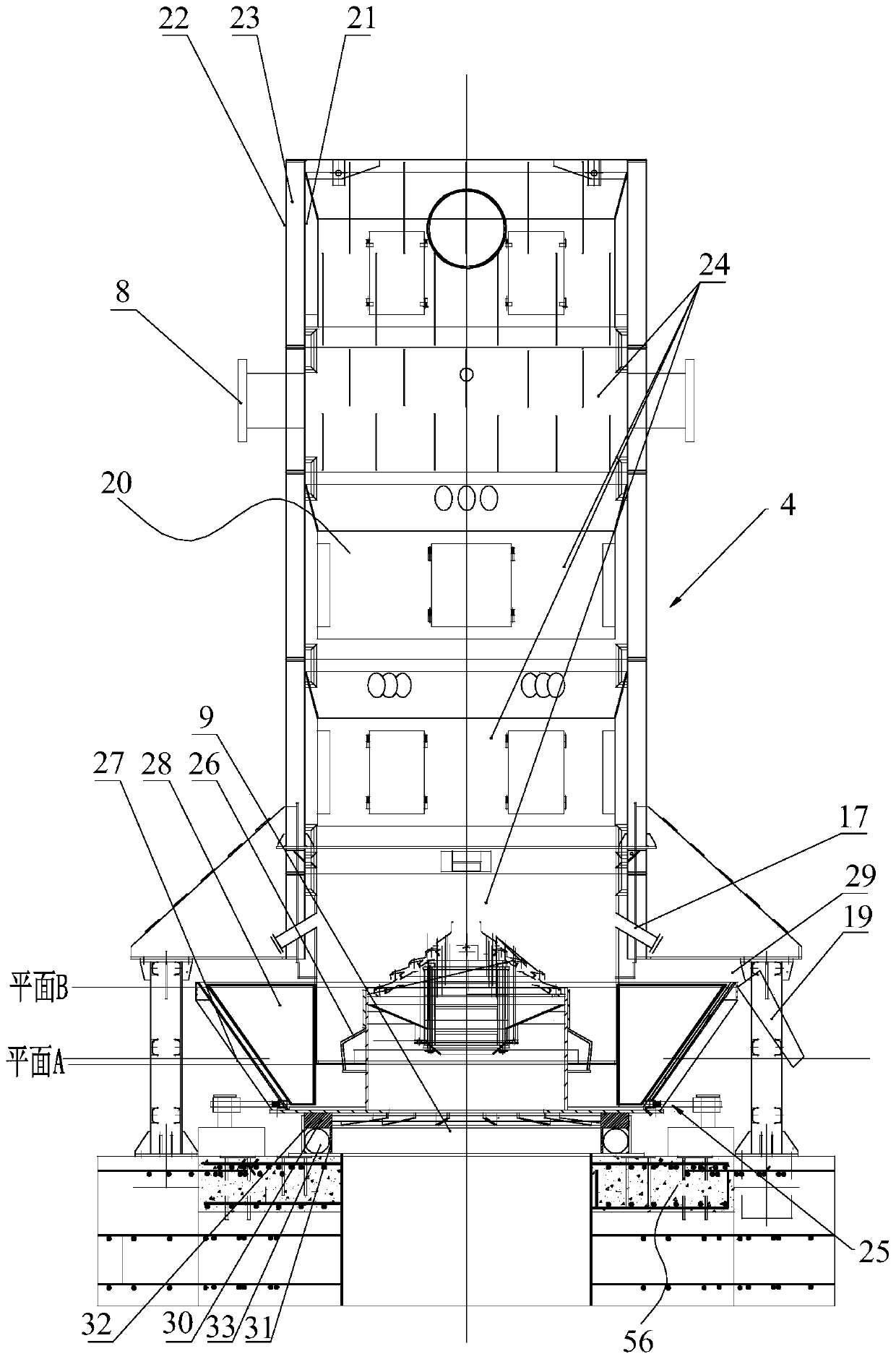

[0068] like Figure 1-7 As shown, a cracking gasification equipment for disposal of garbage, including:

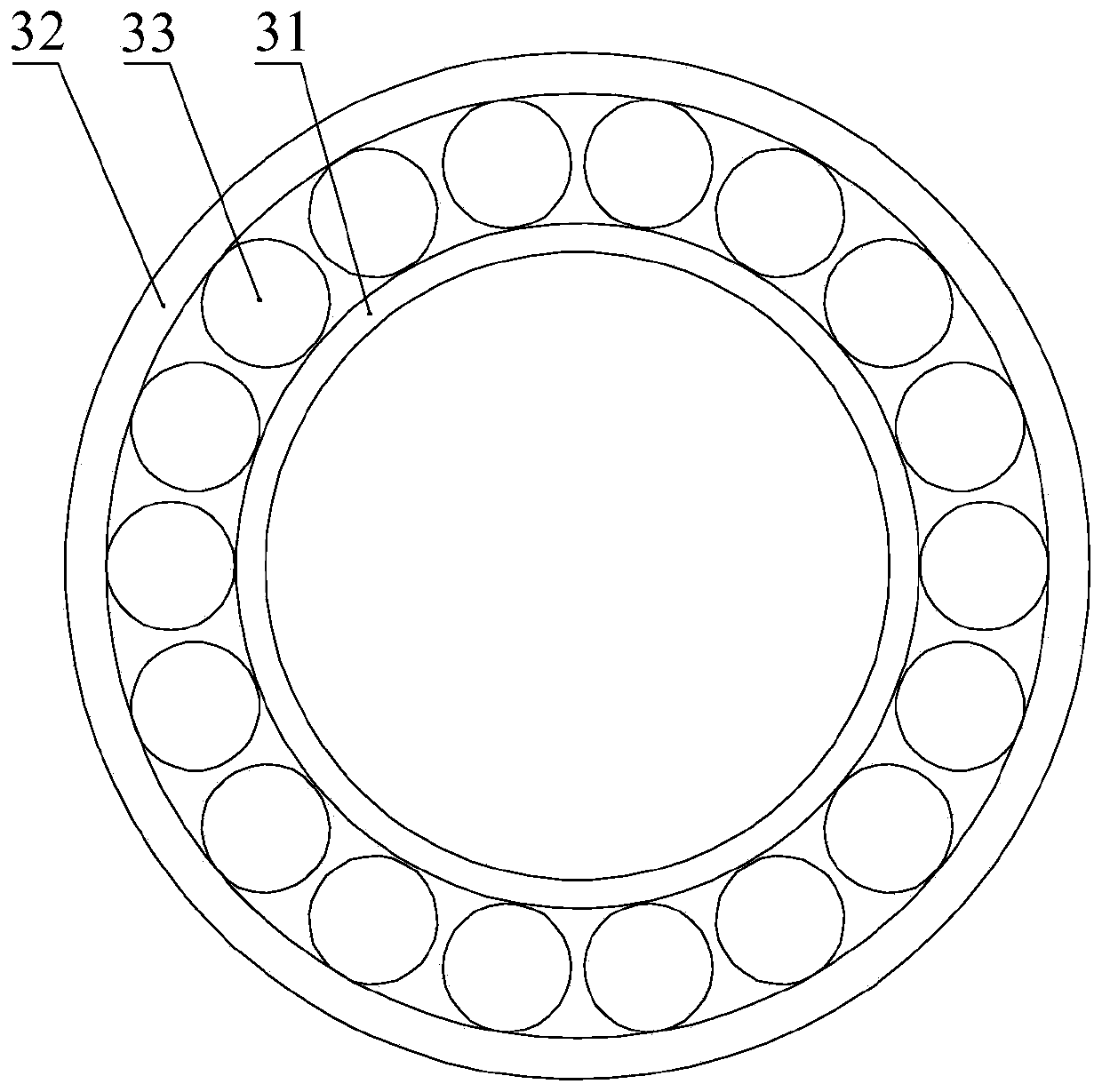

[0069] The cracking gasifier 4 is used for cracking and gasifying materials to form solid slag and gaseous combustible gas. The lower part of the cracking gasifier 4 has a grate 9, and the upper part has at least one gas outlet 8;

[0070] The screw feeding device 3 is arranged above the cracking gasifier 4, and is used to deliver materials to the cracking gasifier 4;

[0071] The feeding hopper 2 is arranged above the screw feeding device 3, and is used for buffering materials and allowing the materials to enter the screw feeding device 3;

[0072] The air blast system 7 is used to provide oxygen to the cracking gasifier 4;

[0073] Slag conveying mechanism 5, for receiving the slag from cracking gasifier 4;

[0074] The fuel injection system 6 is used to inject...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com