Energy-saving quenching launder

An energy-saving, trough technology, applied in quenching devices, heat treatment equipment, manufacturing tools, etc., can solve problems such as the inability to meet the requirements of the quenching flow rate of the piston rod, quenching deformation, etc., and achieve obvious energy-saving effect, cost saving, power configuration small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

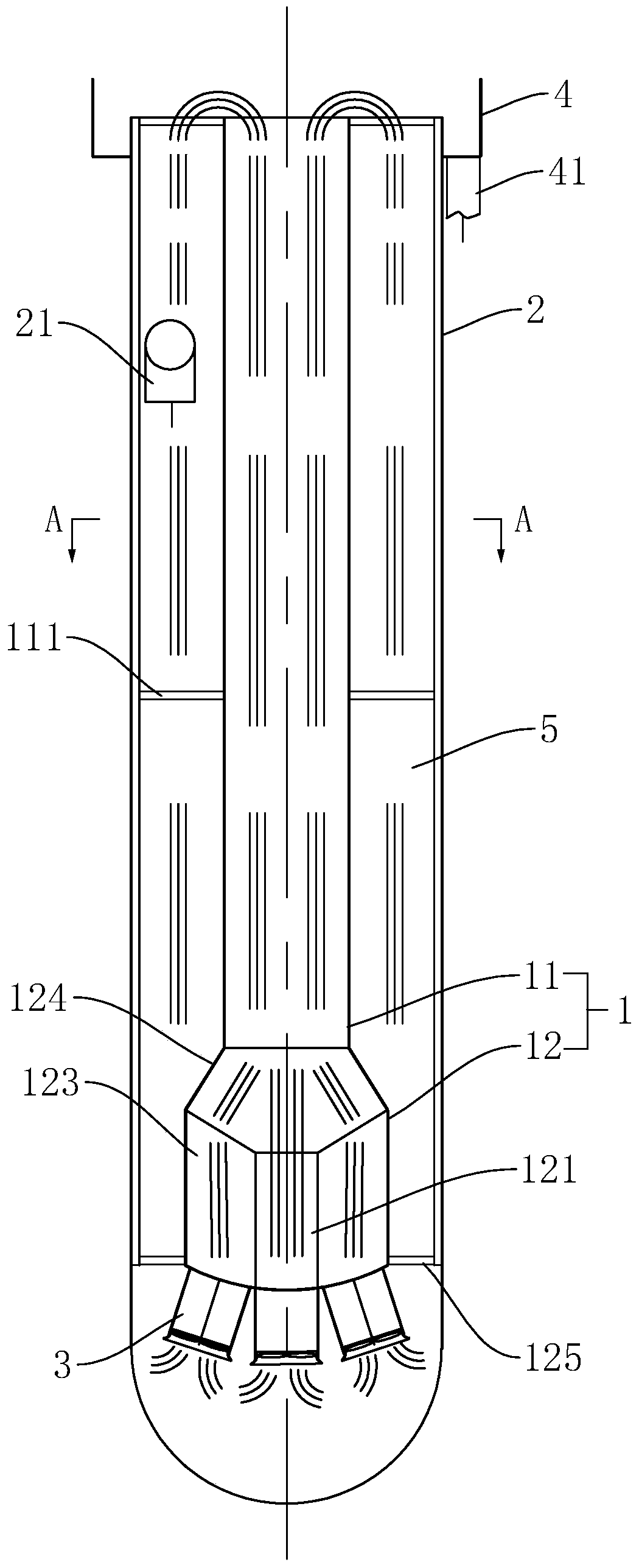

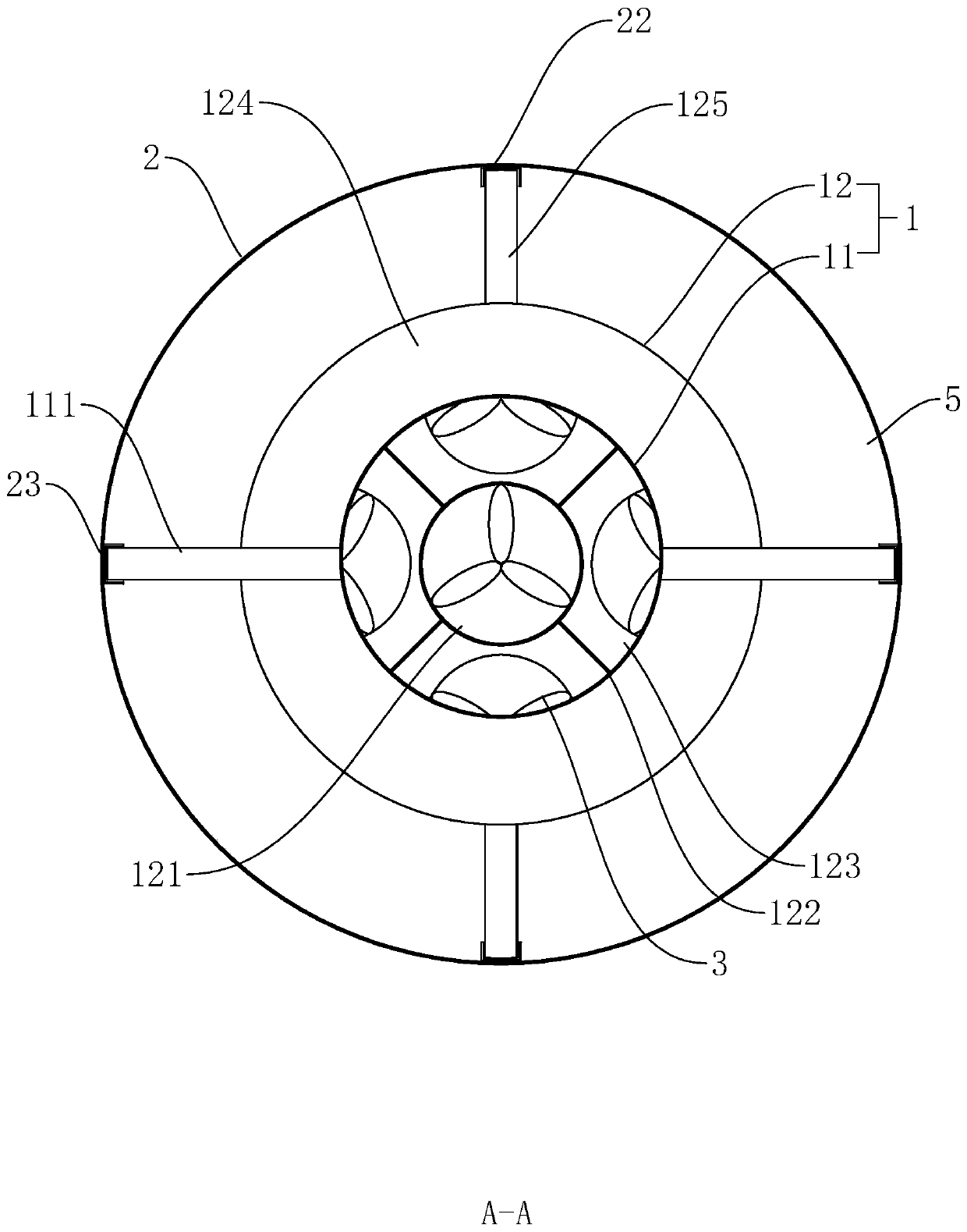

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0033] Such as figure 1 As shown, it is an energy-saving quenching launder disclosed by the present invention, which includes a quenching inner cylinder 1 and an outer cylinder 2 installed coaxially inside and outside. The quenching inner cylinder 1 includes a quenching working area 11 connected up and down and a dynamic pressure energy storage In the area 12, the inner side wall of the installation outer cylinder 2 is symmetrically provided with the installation groove 22 and the positioning groove 23 along its axial direction, and the side walls located in the dynamic pressure energy storage area 12 and the quenching work area 11 are respectively symmetrically fixed with installation grooves along their respective axial directions. The axis of the rod 125 and the positioning rod 111 , and the mounting rod 125 and the positioning rod 111 are perpendicular t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com