Construction method of waterproof operation on basement floor with multiple anti-floating anchor nodes

A technology of basement floor and construction method, which is applied in basic structure engineering, protection devices, construction, etc., can solve the problems of difficult implementation, long construction period, increase engineering cost, etc., so as to achieve safe and reliable waterproof engineering quality, reduce engineering costs, and improve The effect of construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The waterproof construction method of the present invention on the basement floor of the multi-resistance floating anchor rod node comprises the following steps:

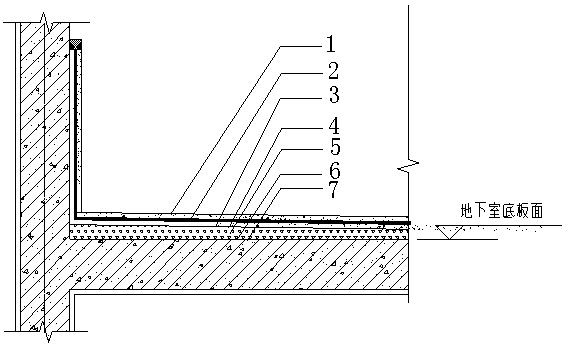

[0031] see now figure 1 , figure 1 It is a schematic diagram of the waterproof structure of the deep foundation pit basement floor according to the embodiment of the present invention.

[0032] a. According to the waterproof design of the basement floor, the construction raw materials are prepared after the design unit confirms the construction plan.

[0033] b. After the construction of the basement floor is completed, the surface of the basement floor is brushed with 1:2.5 cement paste, and the ground is brushed and brushed. The thickness of the cement paste is 3mm.

[0034] c. Brush the roughened surface of the basement bottom plate with waterproof mortar for leveling, so that the slope of the waterproof mortar leveling layer is 2%, and the thickness of the waterproof mortar is 20mm.

[0035] d. After l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com