Device using magnesium slag as desulfurizing agents in fluidized bed boiler

A fluidized bed and boiler furnace technology, applied in the field of fluidized bed boilers, can solve the problem of low temperature of magnesium slag, and achieve the effects of realizing reuse, saving desulfurization costs, and reducing the amount of limestone.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail through the accompanying drawings and specific embodiments below.

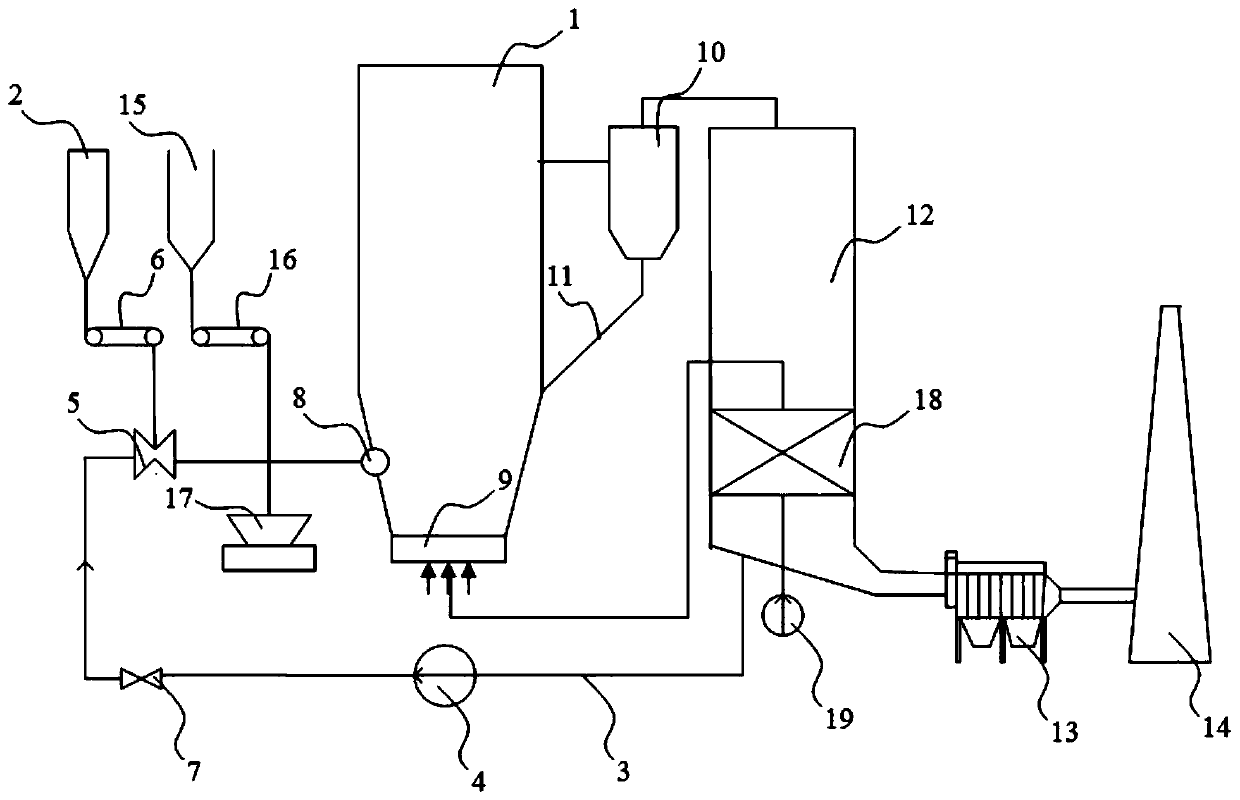

[0020] Such as figure 1 As shown, the present invention provides a device utilizing magnesium slag as a desulfurizing agent in a fluidized bed boiler 1 furnace. A flue 12, a dust removal device 13 and a chimney 14 are sequentially arranged at the tail of the boiler 1. Circulating air pipe 3 , the circulating air pipe 3 is connected to the slag spraying port 8 of the boiler 1 , and the slag spraying port 8 is arranged 3-4m above the air distribution plate 9 of the boiler 1 . A flue gas recirculation fan 4 and a Venturi mixer 5 are sequentially arranged on the circulating air duct 3 .

[0021] Magnesium-containing waste slag is arranged in the magnesium-containing waste slag 2, the mass fraction of magnesium oxide in the magnesium-containing waste slag is ≥ 55%, and the particle size of carbide slag and magnesium-containing waste slag is 100-150 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com