Manufacturing process of low electromagnetic interference power device terminal structure

A technology that interferes with power and manufacturing process. It is used in semiconductor/solid-state device manufacturing, electrical solid-state devices, and electrical components. It can solve the problem of increasing device process steps, reducing high-frequency and high-amplitude electromagnetic interference, and increasing device switching losses. problem, to achieve the effect of alleviating EMI noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

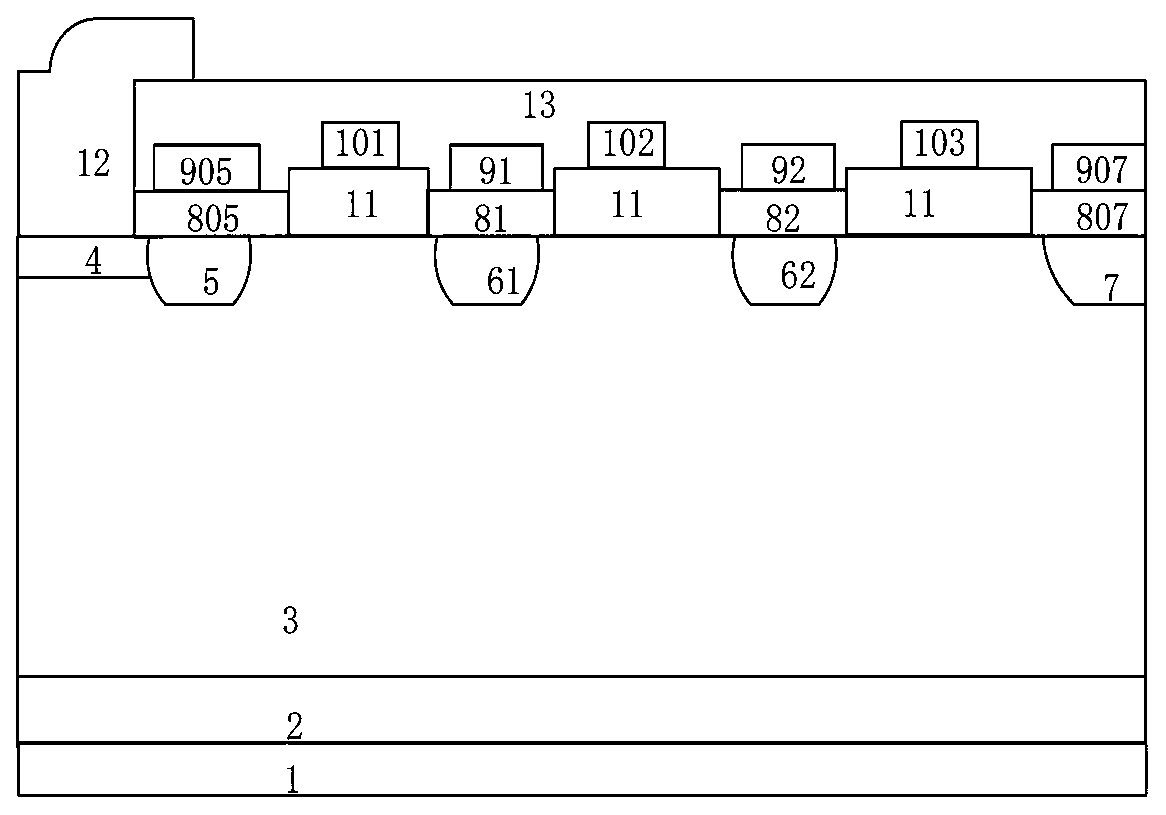

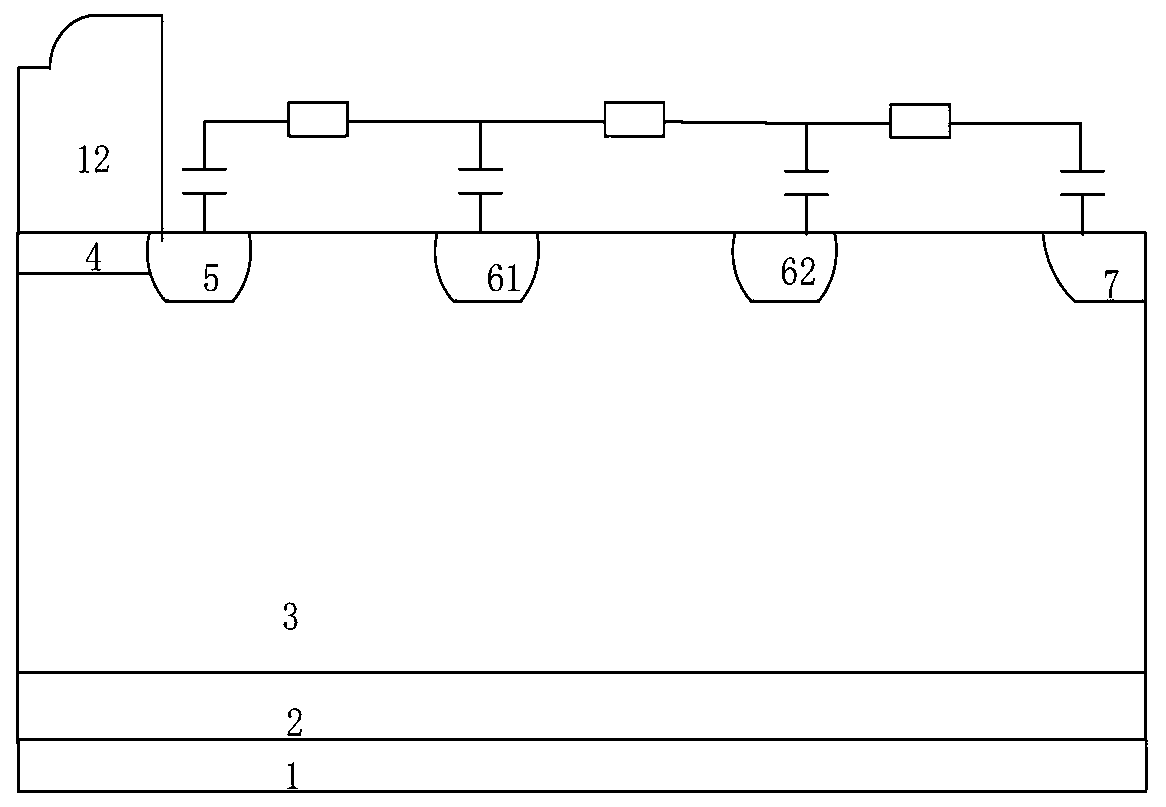

[0014] Hereinafter, the terminal structure of the low electromagnetic interference power device of the present invention will be described in detail with reference to exemplary embodiments.

[0015] figure 1 A schematic flow chart of an exemplary embodiment of the manufacturing process of the low electromagnetic interference power device terminal structure of the present invention is shown.

[0016] Such as figure 1 As shown, in an exemplary embodiment of the present invention, the manufacturing process of the low electromagnetic interference power device terminal structure includes the following steps:

[0017] S01, growing a first conductivity type semiconductor epitaxial layer on a first conductivity type semiconductor substrate. The first conductivity type semiconductor epitaxial layer may have a predetermined withstand voltage requirement and a predetermined thickness, for example, the predetermined withstand voltage requirement may be 600V or higher; the predetermined ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com