PtAg nanocrystal with porous double hollow sphere structure, preparation method and application thereof

A technology of nanocrystals and nanocrystal materials, applied in the field of Pt-based alloy nanocrystals, can solve problems such as unstable structures and few active sites, and achieve the effects of reducing energy consumption, simple preparation methods, and simple operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

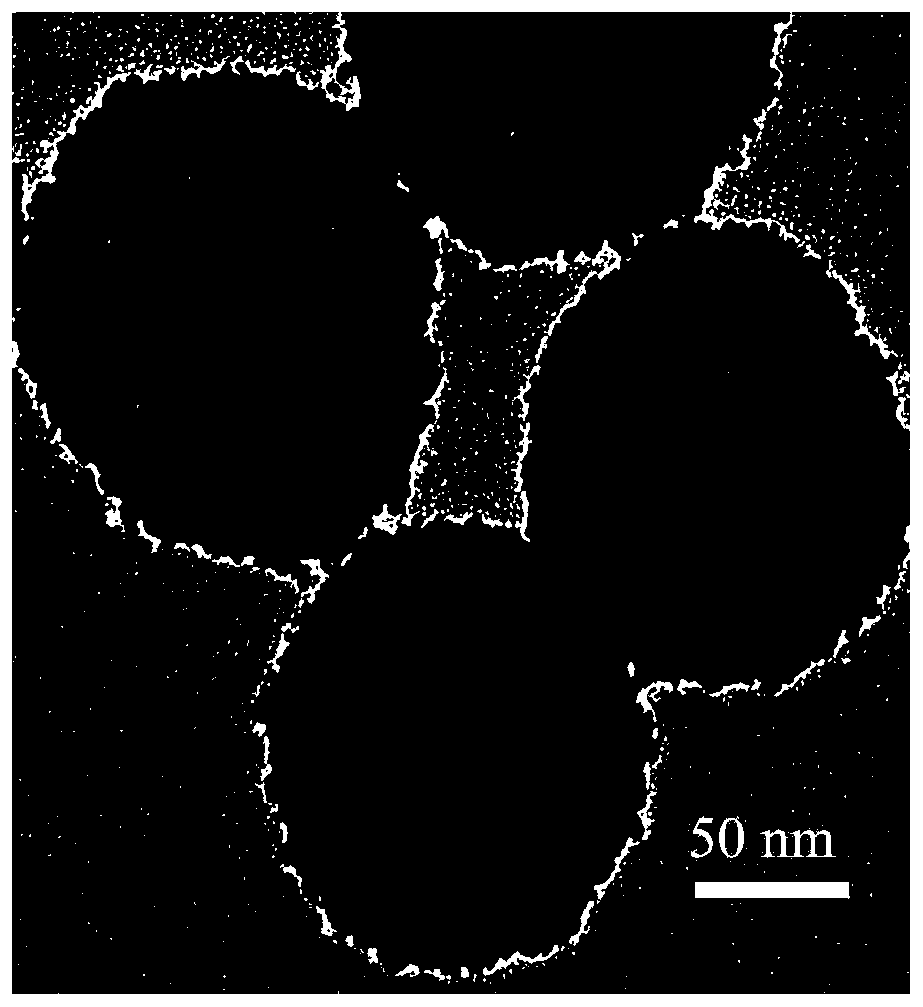

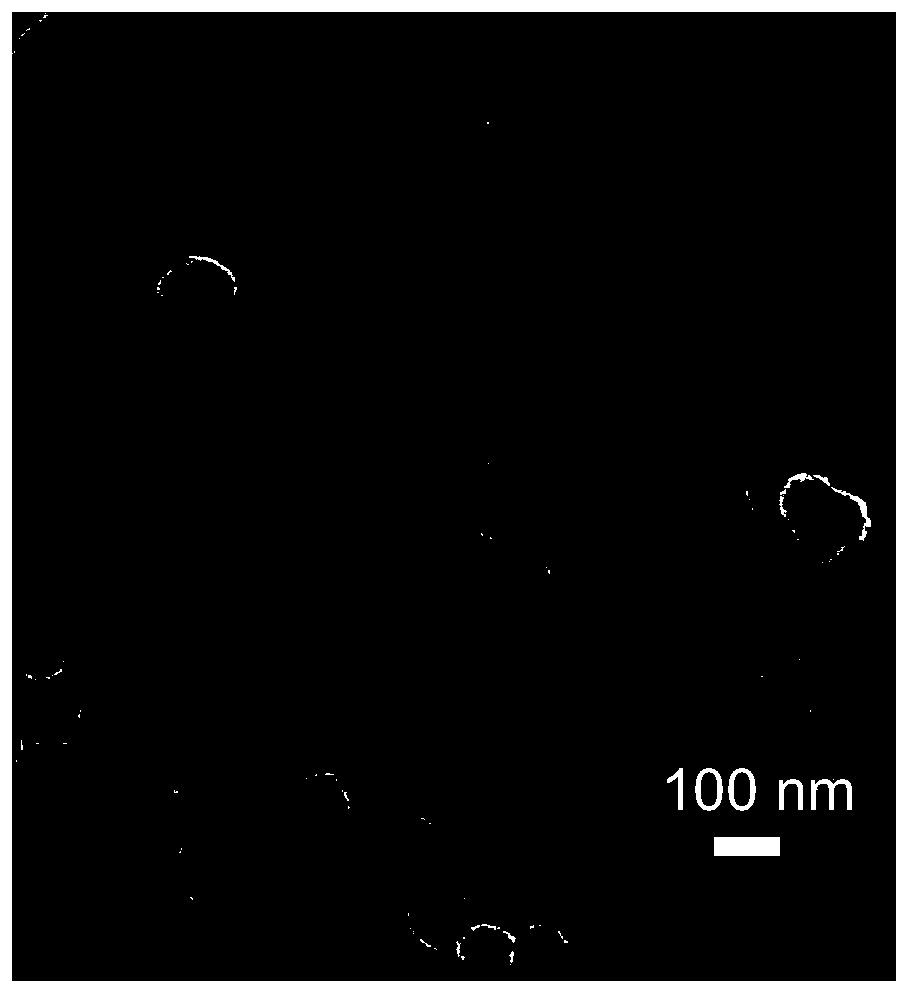

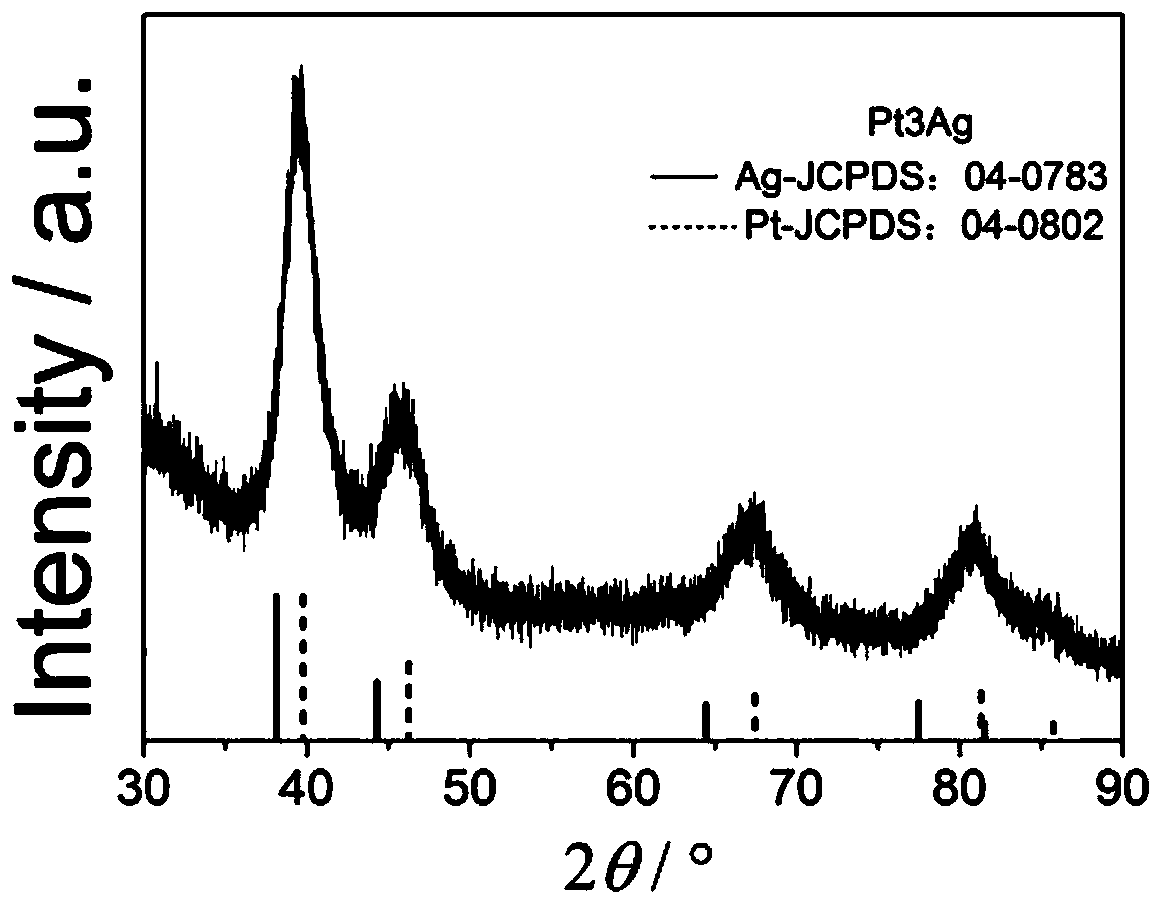

[0035] A preparation method of porous double hollow sphere PtAg nanocrystals, comprising the following steps:

[0036] 1) Preparation of reaction solution: 8 mL of water was used as solvent, and 0.75 mL of 0.05M H 2 PtCl 6 aqueous solution with 0.25mL 0.05M AgNO 3 After the aqueous solution is mixed, it is fully ultrasonicated to make it uniform, and then 10mL (10mg / mL) N'N-methylenebisacrylamide is added, and ultrasonically mixed evenly.

[0037] 2) Preparation of porous double hollow sphere PtAg nanocrystals: put the above reaction solution in an oven at 160°C for 4 hours, after cooling to room temperature, centrifuge the obtained black precipitate at 10,000 rpm for 5 minutes, and wash it with ethanol four times. The porous double hollow sphere PtAg nanocrystals are obtained.

Embodiment 2

[0039] A preparation method of porous double hollow sphere PtAg nanocrystals, comprising the following steps:

[0040] 1) Preparation of reaction solution: 8 mL of water was used as solvent, and 0.75 mL of 0.05M H 2 PtCl 6 aqueous solution with 0.25mL 0.05M AgNO 3 After the aqueous solution is mixed, it is fully ultrasonicated to make it uniform, and then 1 mL (10 mg / mL) N’N-methylenebisacrylamide is added, and ultrasonically mixed evenly.

[0041] 2) Preparation of porous double hollow sphere PtAg nanocrystals: put the above reaction solution in an oven at 160°C for 4 hours, after cooling to room temperature, centrifuge the obtained black precipitate at 10,000 rpm for 5 minutes, and wash it with ethanol four times. The porous double hollow sphere PtAg nanocrystals are obtained.

Embodiment 3

[0043] A kind of preparation method of the preparation method of porous double hollow sphere PtAg nano crystal, comprises the following steps:

[0044]1) Preparation of reaction solution: 8 mL of water was used as solvent, and 0.75 mL of 0.05M H 2 PtCl 6 aqueous solution with 0.25mL 0.05M AgNO 3 After the aqueous solution is mixed, it is fully ultrasonicated to make it evenly mixed, and then 10mL (100mg / mL) N’N-methylenebisacrylamide is added, and ultrasonically mixed evenly.

[0045] 2) Preparation of porous double hollow sphere PtAg nanocrystals: put the above reaction solution in an oven at 160°C for 4 hours, after cooling to room temperature, centrifuge the obtained black precipitate at 10,000 rpm for 5 minutes, and wash it with ethanol four times. The porous double hollow sphere PtAg nanocrystals are obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com