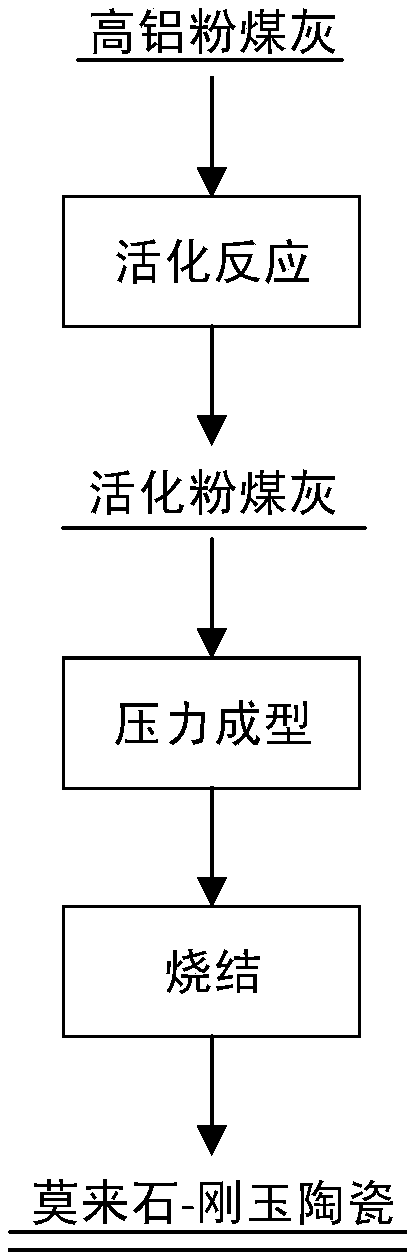

Method for preparing mullite-corundum ceramic from high-aluminum fly ash

A technology for high-alumina fly ash and mullite, which is applied in the field of preparing mullite-corundum ceramics, can solve the problems of low addition amount of fly ash, difficulty in realizing resource utilization of fly ash, etc. The effect of good comprehensive practical performance and large stockpile

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] In this example, the fly ash of a thermal power plant in the Inner Mongolia Autonomous Region is used as a raw material, and the mullite-corundum ceramics are prepared according to the following steps:

[0048] (1) Ball mill the high-aluminum fly ash to -200 mesh, then add it to a high-temperature and high-pressure reactor, mix it with a NaOH solution with a concentration of 1mol / L according to a liquid-solid ratio of 2:1, and close the reactor to stir for activation reaction , the reaction temperature is 150°C, and the reaction time is 24h. After the reaction is completed, the slurry is filtered, washed, and dried to obtain activated fly ash;

[0049] (2) Add water to the activated fly ash obtained in step (1), control the moisture content of the activated fly ash to 15wt%, then place the powder in the mold and utilize a tablet press to form, the molding pressure is 10MPa, dry After getting the green body;

[0050] (3) Put the green body obtained in step (2) into an e...

Embodiment 2

[0053] In this example, the fly ash of a thermal power plant in Shanxi Province is used as a raw material, and the mullite-corundum ceramics are prepared according to the following steps:

[0054] (1) Ball mill the high-aluminum fly ash to -200 mesh, then add it to a high-temperature and high-pressure reactor, mix it with a NaOH solution with a concentration of 5mol / L according to a liquid-solid ratio of 2:1, and close the reactor to stir for activation reaction , the reaction temperature is 50°C, and the reaction time is 10h. After the reaction is completed, the slurry is filtered, washed, and dried to obtain activated fly ash;

[0055] (2) Add water to the activated fly ash obtained in step (1), control the moisture content of the activated fly ash to 10wt%, then place the powder in the mold and utilize a tablet press to form, the molding pressure is 25MPa, dry After getting the green body;

[0056] (3) Place the green body obtained in step (2) in an electric heating furnac...

Embodiment 3

[0059] In this example, the fly ash of a thermal power plant in Tianjin is used as a raw material, and the mullite-corundum ceramics are prepared according to the following steps:

[0060] (1) Ball mill the high-aluminum fly ash to -200 mesh, then add it to a high-temperature and high-pressure reactor, mix it with a NaOH solution with a concentration of 2mol / L according to a liquid-solid ratio of 10:1, close the reactor and stir for activation reaction , the reaction temperature is 90°C, and the reaction time is 3h. After the reaction is completed, the slurry is filtered, washed, and dried to obtain activated fly ash;

[0061] (2) Add water to the activated fly ash obtained in step (1), control the moisture content of the activated fly ash to 8wt%, then place the powder in the mold and utilize a tablet press to form, the molding pressure is 50MPa, dry After getting the green body;

[0062] (3) Place the green body obtained in step (2) in an electric heating furnace for sinter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com