Wear-resistant super-hydrophobic coating layer and preparation method thereof

A super-hydrophobic coating and hydrophobic technology, applied in coatings, polyurea/polyurethane coatings, etc., can solve the problems of complex operation, harsh preparation conditions, and cumbersome preparation methods, and achieve simple preparation process, excellent wear resistance, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

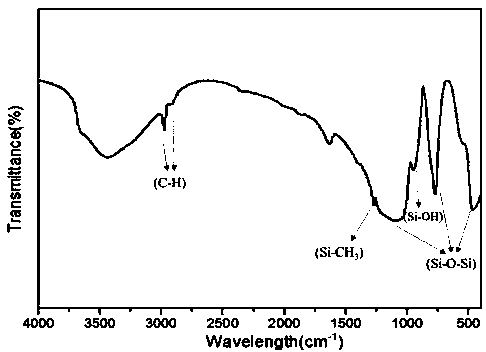

[0028] (1) Mix 12.4mL tetraethyl orthosilicate and 97.2mL absolute ethanol, reflux and stir at 60°C for 10min, then add dropwise a mixture of 11.8mL ammonia water and 1mL deionized water, and reflux at 60°C Stir for 2h, then add 5.5mL of triethoxymethylsilane dropwise, continue to reflux at 60°C for 1h, then age at room temperature for 24h, and then place it in an oven at 60°C for 2 days to completely evaporate the solvent to obtain hydrophobic Silica nanoparticles;

[0029] (2) Add 1 g of hydrophobic silica nanoparticles to 3.95 g of absolute ethanol, and stir vigorously at 60°C for 1 hour to disperse the hydrophobic silica nanoparticles evenly in absolute ethanol to obtain hydrophobic silica nanoparticles Particle dispersion; mix 1g of one-component water-based polyurethane with 1g of water evenly to obtain a one-component water-based polyurethane aqueous solution;

[0030] (3) After mixing 1 part of the one-component water-based polyurethane aqueous solution in step (2) an...

Embodiment 2

[0033] (1) Mix 37.2mL tetraethyl orthosilicate and 291.6mL absolute ethanol, reflux and stir at 60°C for 10min, then add dropwise a mixture of 35.4mL ammonia water and 3mL deionized water, and reflux at 60°C Stir for 2h, then add 16.5mL of triethoxymethylsilane dropwise, continue to reflux at 60°C for 1h, then age at room temperature for 24h, and then place it in an oven at 60°C for 3 days to completely evaporate the solvent to obtain a hydrophobic Silica nanoparticles;

[0034] (2) Add 5g of hydrophobic silica nanoparticles to 19.75g of absolute ethanol, and stir vigorously at 60°C for 1h to disperse the hydrophobic silica nanoparticles evenly in absolute ethanol to obtain hydrophobic silica nanoparticles Particle dispersion; 5g of one-component water-based polyurethane is uniformly mixed with 5g of water to obtain a one-component water-based polyurethane aqueous solution;

[0035](3) After mixing 1 part of the one-component water-based polyurethane aqueous solution in step ...

Embodiment 3

[0038] (1) Mix 12.4mL tetraethyl orthosilicate and 97.2mL absolute ethanol, reflux and stir at 60°C for 10min, then add dropwise a mixture of 11.8mL ammonia water and 1mL deionized water, and reflux at 60°C Stir for 2h, then add 5.5mL of triethoxymethylsilane dropwise, continue to reflux at 60°C for 1h, then age at room temperature for 24h, and then place it in an oven at 60°C for 2 days to completely evaporate the solvent to obtain hydrophobic Silica nanoparticles;

[0039] (2) Add 0.8g of hydrophobic silica nanoparticles to 3.95g of absolute ethanol, and stir vigorously at 60°C for 1h to disperse the hydrophobic silica nanoparticles evenly in absolute ethanol to obtain hydrophobic silica Nanoparticle dispersion; 1g of one-component water-based polyurethane is uniformly mixed with 1g of water to obtain a one-component water-based polyurethane aqueous solution;

[0040] (3) After mixing 1 part of the one-component water-based polyurethane aqueous solution in step (2) and 1 pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com