Method for monitoring growth process of organic pollutant on membrane surface of MBR in real time

A technology for organic pollutants and growth process, which is applied in the field of real-time monitoring of the growth process of organic pollutants on the MBR membrane surface, can solve the problems of inability to monitor the pollution on the membrane surface, and achieve the effects of slowing down membrane pollution, convenient operation and improving properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

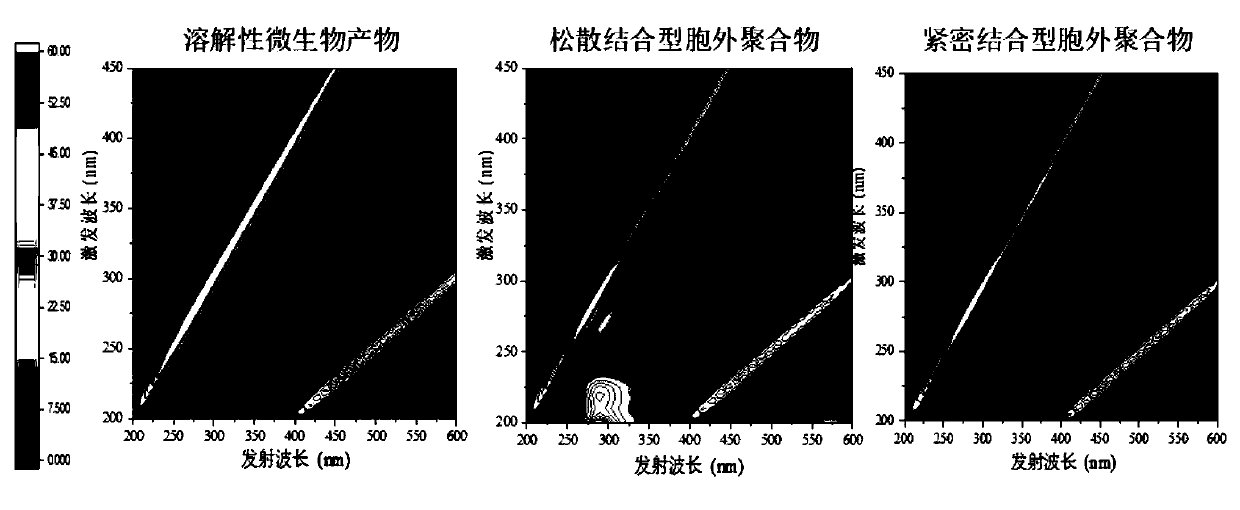

[0050] A method for monitoring the growth process of organic pollutants on the MBR membrane surface in real time, comprising the steps of:

[0051] (1) Titanium wire is used to wrap the membrane surface, and the membrane surface is divided into several 1cm×1cm squares by titanium wire. The membrane is connected with a vacuum gauge and placed in an MBR to treat urban domestic sewage;

[0052] (2) When the transmembrane pressure difference rises to 1kPa, use a syringe to absorb the membrane surface pollutants in the grid, dissolve them in 100mL distilled water and shake well;

[0053] (3) Centrifugal filtration was used to extract soluble microbial products, and heat extraction was used to extract extracellular polymers. After the extracts were filtered through a 0.45 μm filter membrane, the concentration of total organic carbon in the extract solution was measured. If its total organic carbon concentration is higher than 20mg / L, dilute it to less than 20mg / L;

[0054] (4) Use ...

Embodiment 2

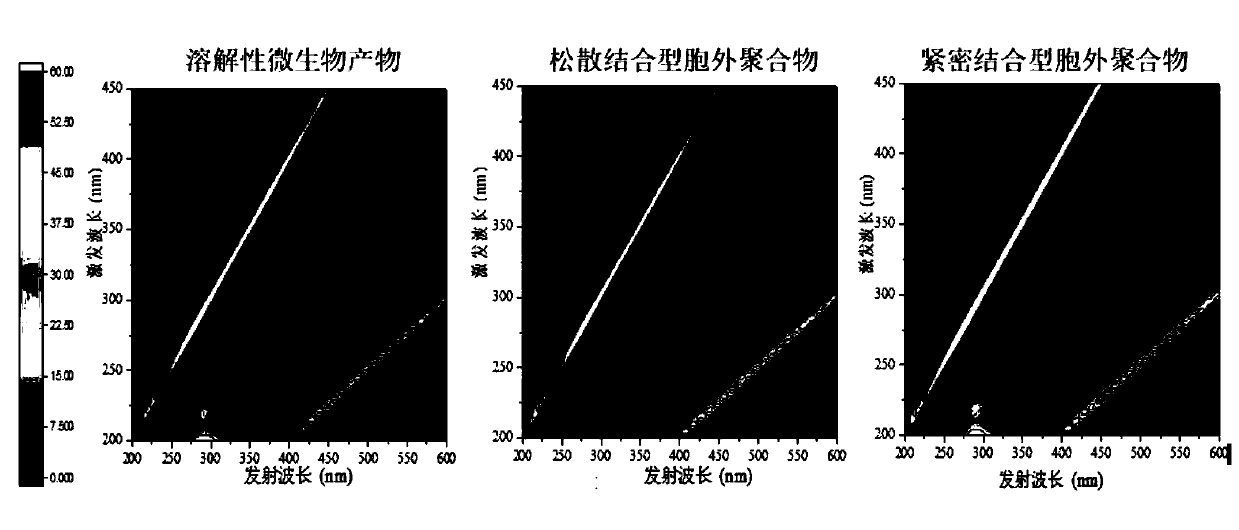

[0058] A method for monitoring the growth process of organic pollutants on the MBR membrane surface in real time, comprising the steps of:

[0059] (1) Titanium wire is used to wrap the membrane surface, and the membrane surface is divided into several 1cm×1cm squares by titanium wire. The membrane is connected with a vacuum gauge and placed in an MBR to treat urban domestic sewage;

[0060] (2) When the transmembrane pressure difference rises to 5kPa, use a syringe to absorb the membrane surface pollutants in the grid, dissolve them in 100mL distilled water and shake well;

[0061] (3) Centrifugal filtration was used to extract soluble microbial products, and heat extraction was used to extract extracellular polymers. After the extracts were filtered through a 0.45 μm filter membrane, the concentration of total organic carbon in the extract solution was measured. If its total organic carbon concentration is higher than 20mg / L, dilute it to less than 20mg / L;

[0062] (4) Use ...

Embodiment 3

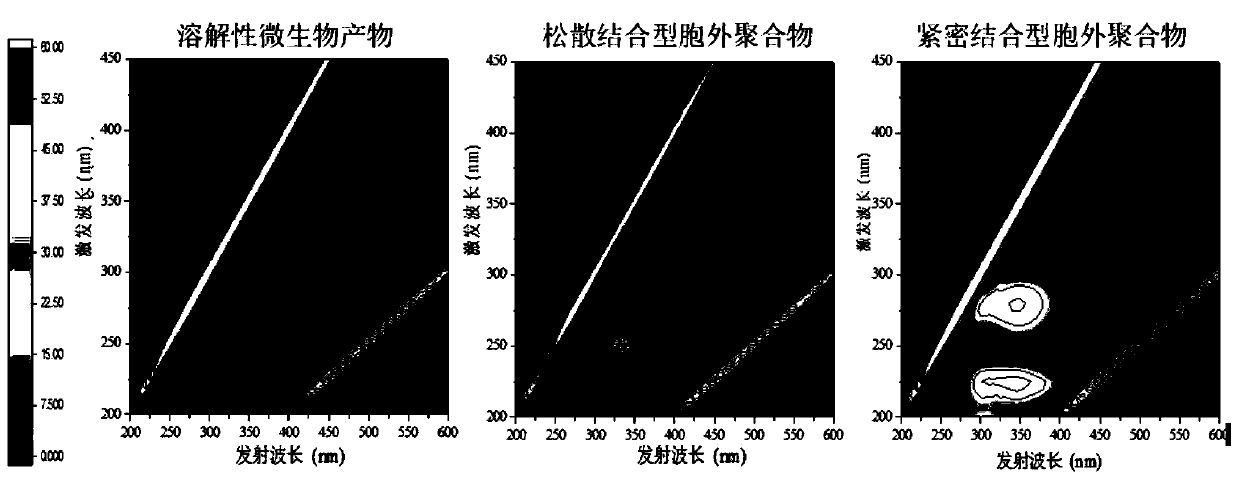

[0066] A method for monitoring the growth process of organic pollutants on the MBR membrane surface in real time, comprising the steps of:

[0067] (1) Titanium wire is used to wrap the membrane surface, and the membrane surface is divided into several 1cm×1cm squares by titanium wire. The membrane is connected with a vacuum gauge and placed in an MBR to treat urban domestic sewage;

[0068] (2) When the transmembrane pressure difference rises to 14kPa, use a syringe to absorb the membrane surface pollutants in the grid, dissolve them in 100mL distilled water and shake well;

[0069] (3) Centrifugal filtration was used to extract soluble microbial products, and heat extraction was used to extract extracellular polymers. After the extracts were filtered through a 0.45 μm filter membrane, the concentration of total organic carbon in the extract solution was measured. If its total organic carbon concentration is higher than 20mg / L, dilute it to less than 20mg / L;

[0070] (4) Use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com