Circuit breaker mechanism

A technology of circuit breaker mechanism and energy storage motor, which is applied to high-voltage air circuit breakers, circuits, electrical components, etc., can solve the problems of inconvenient assembly and maintenance, many parts, and inability to realize voltage interchange, and achieve simple and reliable parts and components. , The effect of compact internal structure, convenient assembly and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

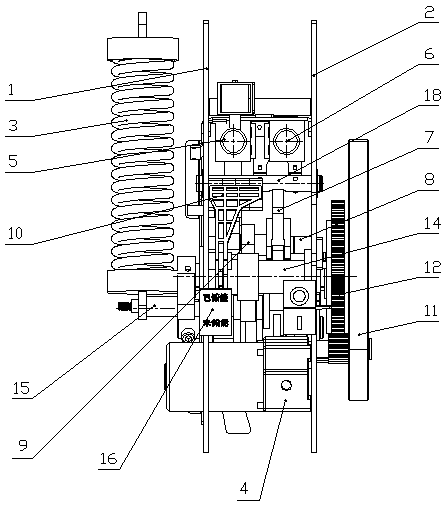

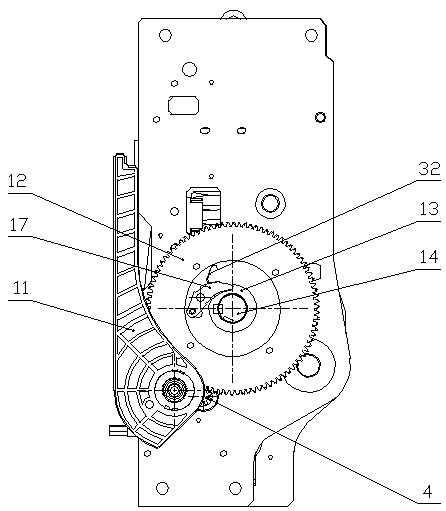

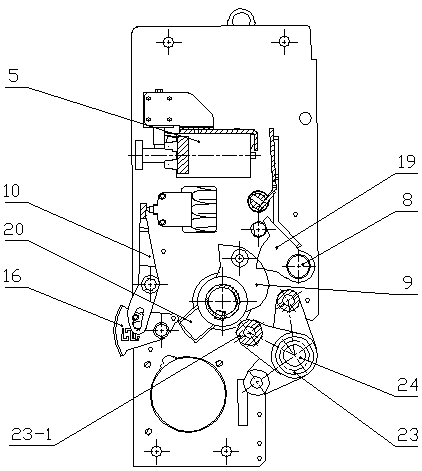

[0026] A circuit breaker mechanism according to the present invention comprises a left side plate (1), a right side plate (2), an energy storage spring (3), an energy storage motor (4), a closing electromagnet (5), an opening Electromagnet (6), opening pinch plate (7), closing branch shaft (8), closing cam (9), pressure plate (10), energy storage handle (11), energy storage gear (12), transmission wheel (13), energy storage shaft (14), rotating spring arm (15), energy storage indicator (16), transmission claw (17), opening half shaft (18), closing detent (19), clutch Cam (20), opening push plate (21), holding block (22), input holding crank arm (23), crank arm support shaft (24), upper air lock plate (25), lower air lock plate (26), chassis inter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com