Porous biological artificial eye seat

A bio-ceramic, prosthetic eye seat technology, applied in eye implants and other directions, can solve the problems of high price, long process and complex process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Use hydroxyapatite: tricalcium phosphate: biological glass 4:2:1, mix 20nm-500nm particle size powder as bioceramic material 50 parts, acrylic resin monomer 40 parts as photosensitive resin binder, 5 parts The PMMA used as a pore-forming agent, 2 parts of polymethylcellulose as a dispersant, and 1 part of MgO as a sintering aid were mixed uniformly with a mixer and then defoamed to obtain a bioceramic slurry for 3D printing.

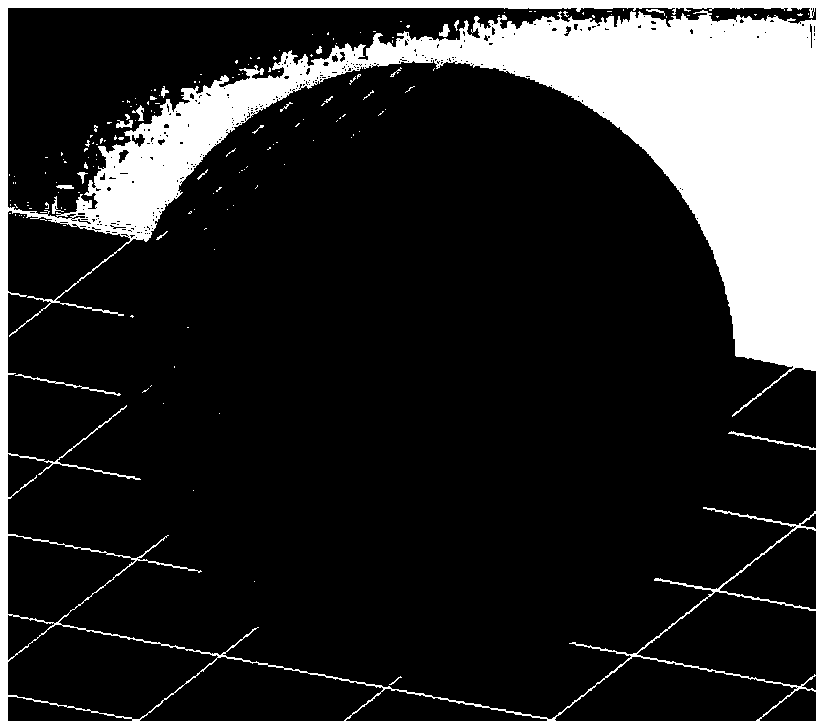

[0034] Modeling of the prosthetic eye socket is carried out based on the scanned eye socket data of the patient. The model of the prosthetic eye socket is a spherical shape with a diameter of 25 mm. The spherical cap with a height of 10 mm on one side is a dense thin shell with a thickness of 1 mm. And the rest of the surface has uniformly distributed pores of 0.3 mm to 1 mm, which are interconnected. The model as figure 1 shown.

[0035] A 3D printer of the Autocera type manufactured by Beijing Shiwei Technology Co., Ltd., which can be used for...

Embodiment 2

[0038] The ellipsoid whose polar radius is greater than the equatorial radius is used as the artificial eye seat model, and the spherical cap with a height of 6mm from a pole is a dense thin shell with a thickness of 2mm, and the inside and the rest of the surface have a uniform distribution of 0.1mm to 0.8mm pores, which are interconnected.

[0039] The prosthetic eye seat was prepared in the same manner as described in Example 1 except for the difference of these models.

Embodiment 3

[0041] Using the 1:1 mixed powder of bioglass and calcium sulfate as the raw material of bioceramic powder, the prosthetic eye seat was prepared in the same manner as described in Example 1. The final sintering temperature is 1200°C for 1h.

[0042] According to the porous prosthetic eye socket of the present invention, 3D printing is used to form designable interconnected holes, and the holes are larger in size than the holes generated by the pore-forming agent (template agent), which is beneficial to newborns. Blood vessels and tissue seep into the porous socket. The secondary holes and the final holes in the prosthetic eye seat of the present invention are small in size and can be used to deliver required nutrients and the like to blood vessels and tissues formed in the macroscopic holes.

[0043] In addition, the porous prosthetic eye socket of the present invention is shaped based on the patient's eye socket data, and its size is more suitable for each patient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com