Methyl isobutyl ketone low-temperature hydrogenation catalyst, preparation method and applications thereof

A technology of methyl isobutyl ketone and hydrogenation catalyst, which is applied in the direction of preparation of hydroxyl compounds, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., and can solve low reaction activity and lack of stability of catalysts And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

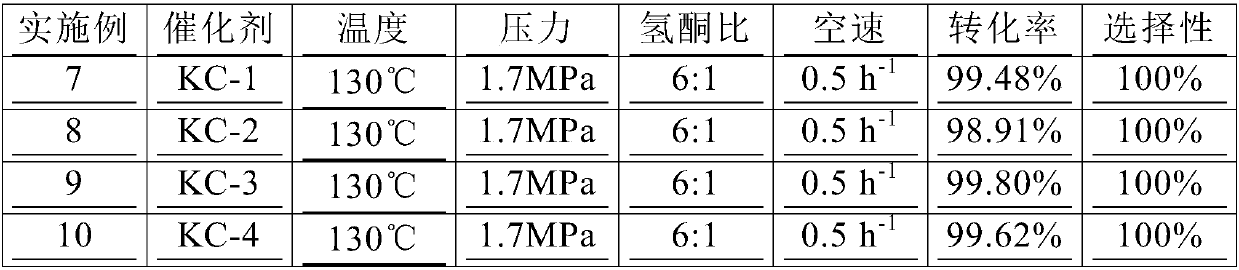

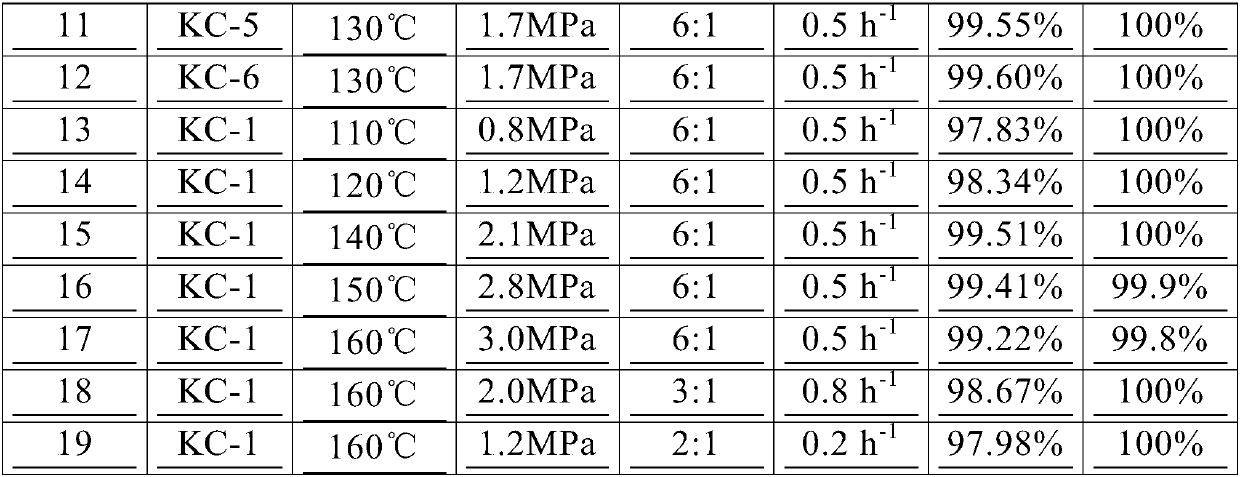

Examples

Embodiment 1

[0065] (1) Powder preparation: Add 190 g of lanthanum nitrate hexahydrate to an aqueous aluminum sulfate solution containing 70 g / L of aluminum oxide in a volume of 30 L, and dissolve aluminum hydroxide with aqueous sodium hydroxide solution to prepare sodium metaaluminate containing 68 g / L of aluminum oxide solution, sodium metaaluminate solution was prepared in excess to adjust the pH value of pseudo-boehmite synthesis. Add 3L of deionized water to the neutralization tank and raise the temperature to 70°C, pour the prepared aluminum sulfate solution and sodium metaaluminate solution into the synthesis tank, and control the temperature in the neutralization tank to 68-72°C In between, fix the flow rate of the aluminum sulfate solution, adjust the flow rate of the sodium metaaluminate solution so that the pH value of the reaction solution in the synthesis tank is 6.8 to 7.2, and stop injecting the sodium metaaluminate solution when the aluminum sulfate solution is injected. Th...

Embodiment 2

[0070] (1) Powder preparation: Add 515 g of lanthanum nitrate hexahydrate to an aqueous aluminum sulfate solution containing 65 g / L of aluminum oxide in a volume of 30 L, and dissolve aluminum hydroxide with aqueous sodium hydroxide solution to prepare sodium metaaluminate containing 65 g / L of aluminum oxide solution, sodium metaaluminate solution was prepared in excess to adjust the pH value of pseudo-boehmite synthesis. Add 3L of deionized water to the neutralization tank and raise the temperature to 66°C, pour the prepared aluminum sulfate solution and sodium metaaluminate solution into the synthesis tank, and control the temperature in the neutralization tank to 65-68°C In between, fix the flow rate of the aluminum sulfate solution, adjust the flow rate of the sodium metaaluminate solution so that the pH value of the reaction solution in the synthesis tank is 7.0 to 7.4, and stop injecting the sodium metaaluminate solution when the aluminum sulfate solution is injected. Th...

Embodiment 3

[0075] (1) Powder preparation: Add 275 g of lanthanum nitrate hexahydrate to an aqueous aluminum sulfate solution containing 66 g / L of aluminum oxide in a volume of 30 L, and dissolve aluminum hydroxide with aqueous sodium hydroxide solution to prepare sodium metaaluminate containing 72 g / L of aluminum oxide solution, sodium metaaluminate solution was prepared in excess to adjust the pH value of pseudo-boehmite synthesis. Add 3L of deionized water to the neutralization tank and raise the temperature to 63°C, pour the prepared aluminum sulfate solution and sodium metaaluminate solution into the synthesis tank, and control the temperature in the neutralization tank to be between 63 and 66°C During this period, the flow rate of the aluminum sulfate solution is fixed, and the flow rate of the sodium metaaluminate solution is adjusted so that the pH value of the reaction solution in the synthesis tank is 7.2 to 7.5. When the aluminum sulfate solution is injected, the sodium metaalum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com