Three-parameter intelligent compensation and correction electrochemical online dissolved oxygen sensor

A dissolved oxygen sensor and conductivity sensor technology, applied in the field of dissolved oxygen content detection, can solve problems such as self-calibration, sensor response speed, poor accuracy, stability, inaccurate detection data, etc., to improve calibration efficiency and accuracy, Improve the anti-interference ability and the effect of accurate detection data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

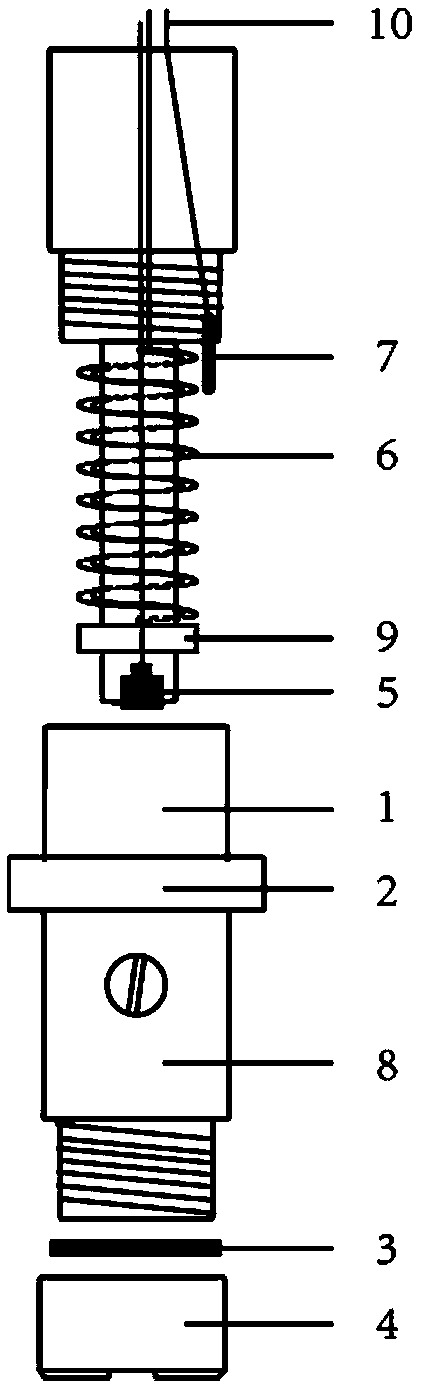

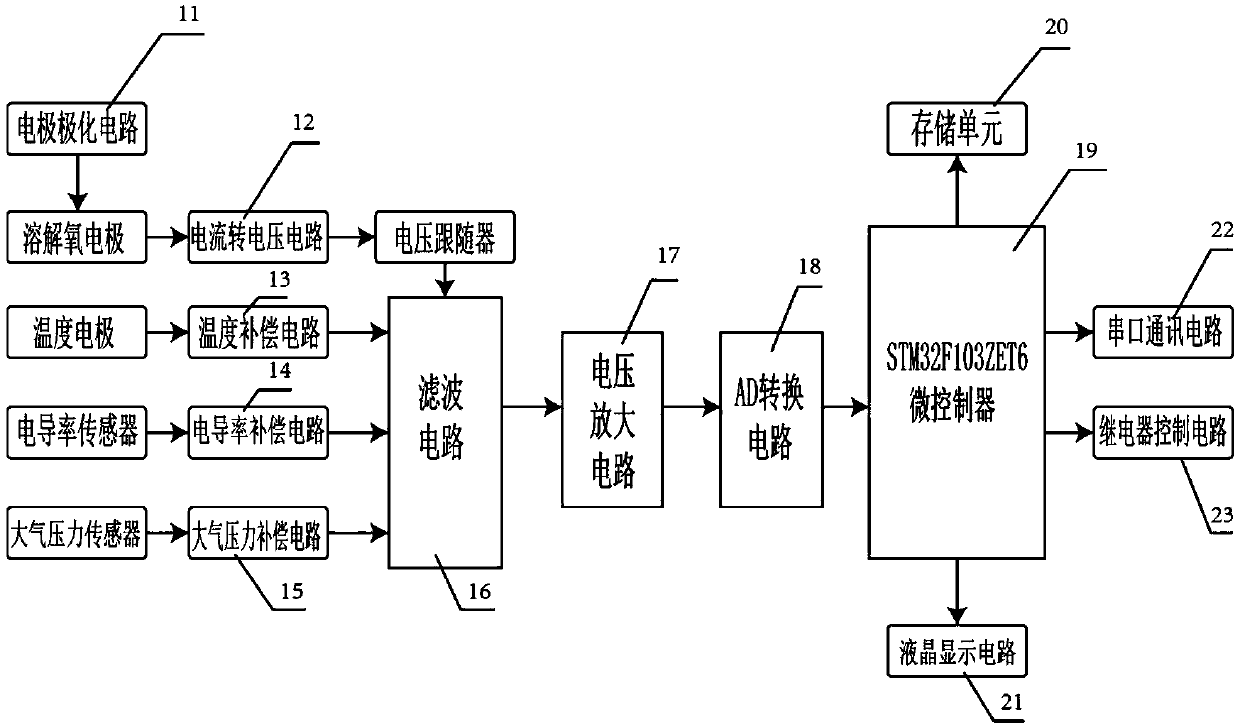

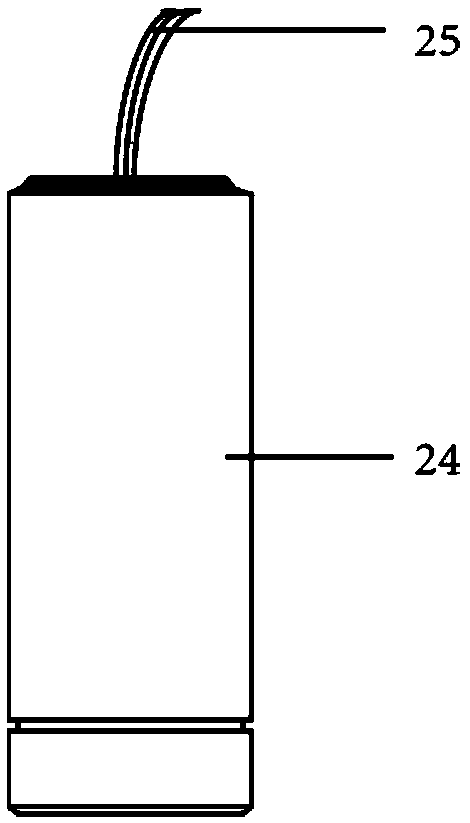

[0023] Embodiment: Provide a three-parameter intelligent compensation and correction electrochemical online dissolved oxygen sensor, including dissolved oxygen electrode 1, conductivity sensor 30, atmospheric pressure sensor 24, temperature electrode 33, measured water sample flow cell 35, sensor bracket 26 and The detection circuit unit, the dissolved oxygen electrode includes a cylindrical shell 2 of the sensor, an oxygen permeable membrane 3, a membrane cover 4, a gold electrode 5 as a working electrode, a silver electrode 6 as an auxiliary electrode, a platinum electrode 7 as a silver protective electrode, Liquid reaction electrolyte 8, electrode base 9 and insulated wire 10; the conductivity sensor 30 includes a conductivity detection unit 31 and a conductivity signal wire 32; the sensor bracket 26 has a dissolved oxygen electrode bracket hole 27, a conductivity Sensor bracket holes 28, temperature electrode bracket holes 29; the dissolved oxygen electrode 1, conductivity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com