Si/MoS2 electrode material preparation method

A technology of electrode materials and quantum dots, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve problems such as poor conductivity and limited development, and achieve improved electrode material performance, close relative positions, and close contact Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Step 1, 0.1 g of sodium ascorbate was dissolved in 10 mL of deionized water to prepare a solution, and then 3.75 mL of sodium ascorbate solution and 1 mL of N-aminoethyl-γ-aminopropyltrimethoxysilane were added to 12 mL of deionized water, Stirring at room temperature for 20 minutes to obtain Si quantum dots;

[0022] Step 2, measure 20mL of deionized water in a beaker, mix 0.7062g (NH 4 ) 6 Mo 7 o 24 ·6H 2 O and 1.3049gH 2 NCSNH 2 Weigh it well and pour it into a beaker, continue the homogenization treatment for 30 minutes, then take 1mL Si and add it to the solution for homogenization treatment again;

[0023] Step 3: The above solution was hydrothermally reacted at 180° C. for 18 hours, and when it was cooled to room temperature, the solution was centrifugally cleaned, and the lower precipitate was left for vacuum drying.

Embodiment 2

[0025] Step 1, 0.1 g of sodium ascorbate was dissolved in 10 mL of deionized water to prepare a solution, and then 3.75 mL of sodium ascorbate solution and 1 mL of N-aminoethyl-γ-aminopropyltrimethoxysilane were added to 12 mL of deionized water, Stirring at room temperature for 20 minutes to obtain Si quantum dots;

[0026] Step 2, measure 20mL of deionized water in a beaker, mix 0.7062g (NH 4 ) 6 Mo 7 o 24 ·6H 2 O and 1.3049gH 2 NCSNH 2 Weigh it well and pour it into a beaker, continue the homogenization treatment for 30 minutes, then take 3mL Si and add it to the solution for homogenization treatment again;

[0027] Step 3: The above solution was hydrothermally reacted at 180° C. for 18 hours, and when it was cooled to room temperature, the solution was centrifugally cleaned, and the lower precipitate was left for vacuum drying.

Embodiment 3

[0029] Step 1, 0.1 g of sodium ascorbate was dissolved in 10 mL of deionized water to prepare a solution, and then 3.75 mL of sodium ascorbate solution and 1 mL of N-aminoethyl-γ-aminopropyltrimethoxysilane were added to 12 mL of deionized water, Stirring at room temperature for 20 minutes to obtain Si quantum dots;

[0030] Step 2, measure 20mL of deionized water in a beaker, mix 0.7062g (NH 4 ) 6 Mo 7 o 24 ·6H 2 O and 1.3049gH 2 NCSNH 2 Weigh it well and pour it into a beaker, continue the homogenization treatment for 30 minutes, then take 5mL Si and add it to the solution for homogenization treatment again;

[0031] Step 3: The above solution was hydrothermally reacted at 180° C. for 18 hours, and when it was cooled to room temperature, the solution was centrifugally cleaned, and the lower precipitate was left for vacuum drying.

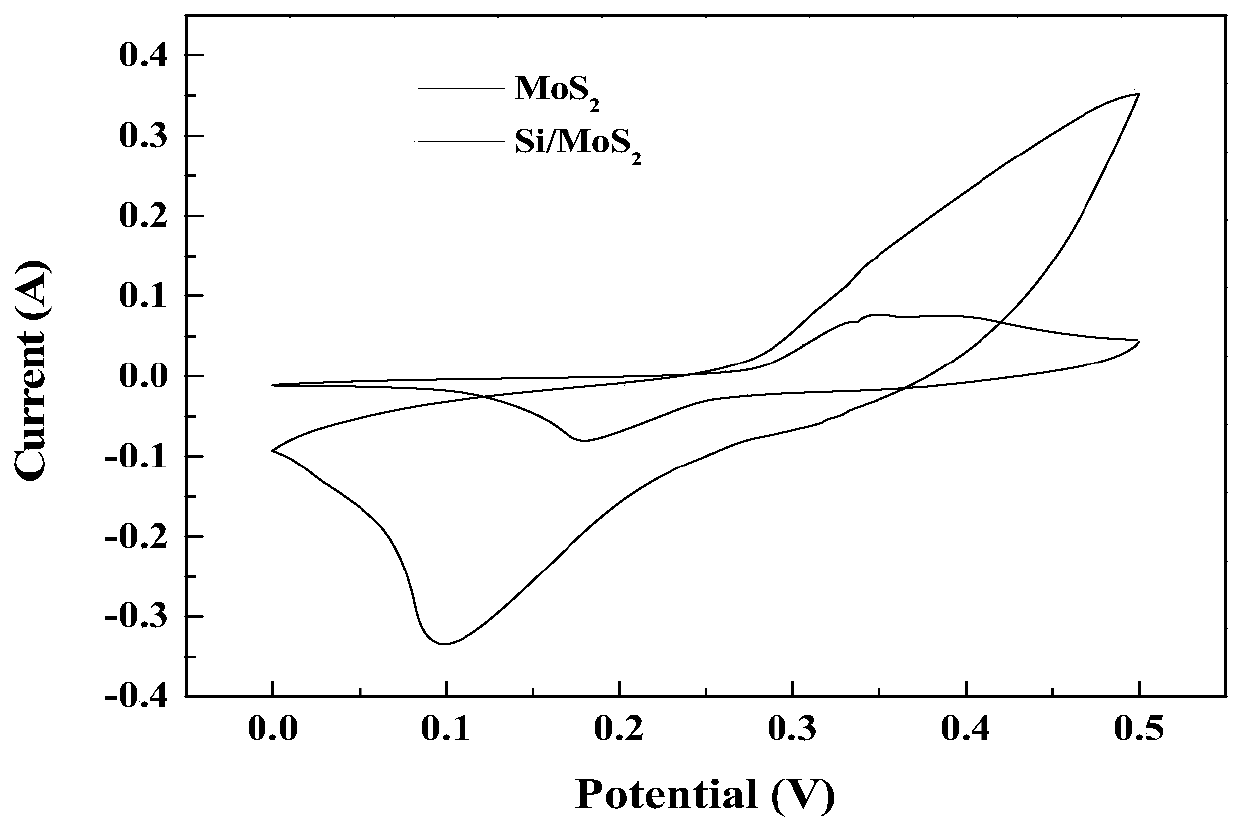

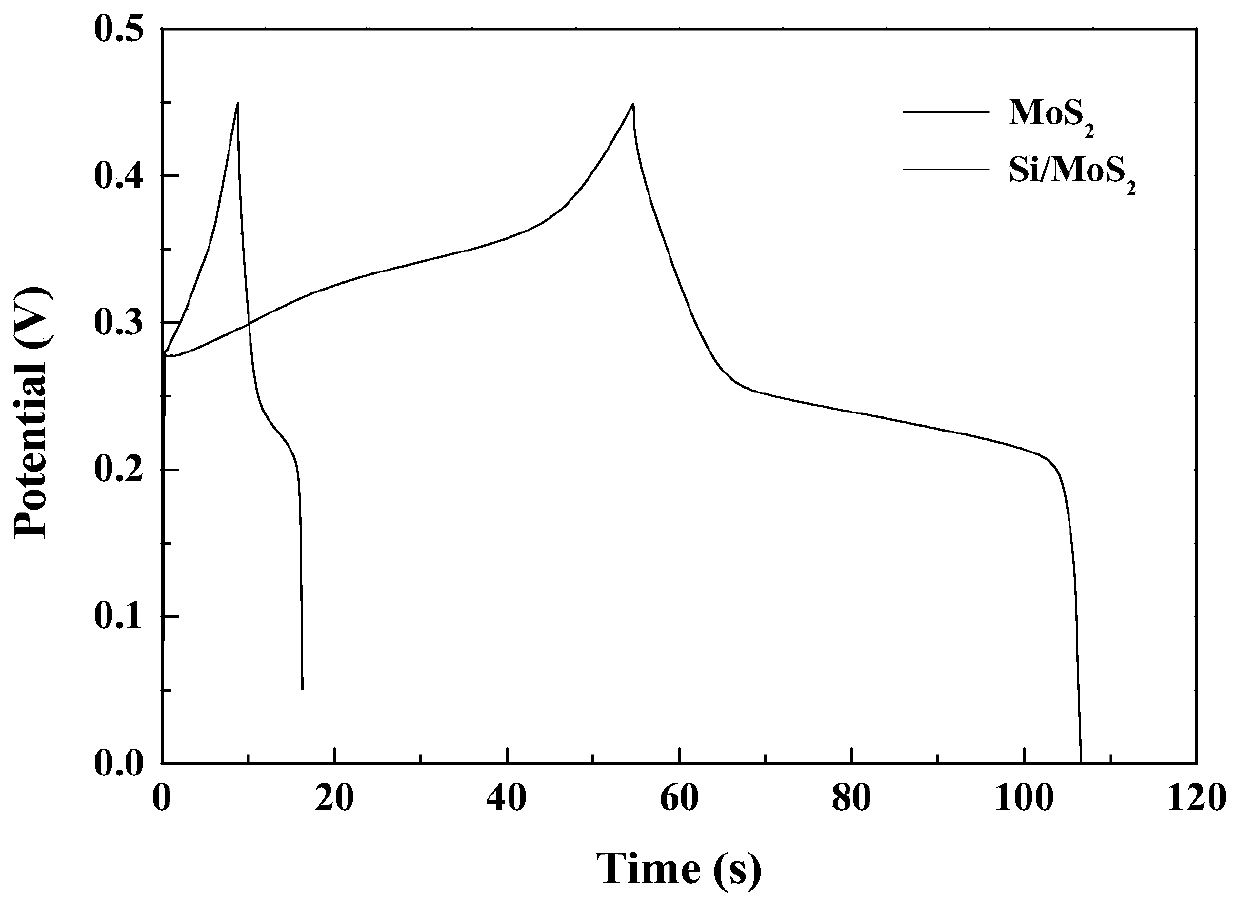

[0032] see figure 1 , figure 2 and image 3 , the present invention and the comparative material MoS without adding Si quantum dots 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com