Chemi-mechanical pulping high-concentration filtrate treatment method

A treatment method and chemi-mechanical pulping technology, applied in chemical/chemomechanical pulp, washing/replacing pulp treatment liquid, concentrating waste liquid, etc., can solve the problems of reduced evaporation efficiency, high treatment cost, difficult operation, etc., so as to improve evaporation Efficiency, use of water resources, the effect of improving mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

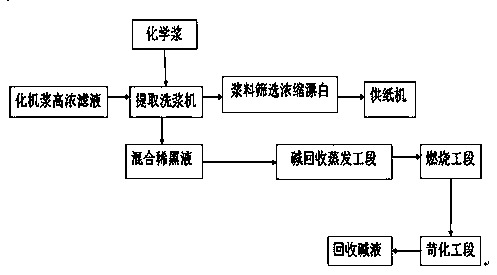

Image

Examples

Embodiment 1

[0021] A method for treating chemical-mechanical pulp high-concentration filtrate, comprising the steps of:

[0022] Step 1: Send the high-concentration filtrate produced by the chemical-mechanical pulp production line into the chemical pulp hot water tank, add washing water and mix according to the ratio of 1:0.8;

[0023] Step 2: Extract the mixture of high-concentration filtrate and washing water in the hot water tank of chemical pulp, mix and thicken part of the mixture of high-concentration filtrate and washing water and slurry, then send it to the drum vacuum pulp washer, and pass through the drum-type vacuum pulp washer. The pulp layer is formed on the net of the vacuum pulp washer, and the mixture of the remaining high-concentration filtrate and washing water is sent to the drum vacuum pulp washer to spray and wash the pulp layer;

[0024] Step 3: Send the mixture of high-concentration filtrate and washing water filtered through the pulp layer in the drum vacuum washer...

Embodiment 2

[0028] A method for treating chemical-mechanical pulp high-concentration filtrate, comprising the steps of:

[0029] Step 1: Send the high-concentration filtrate produced by the chemical-mechanical pulp production line into the chemical pulp hot water tank, add washing water and mix according to the ratio of 1:1.2;

[0030] Step 2: Extract the mixture of high-concentration filtrate and washing water in the hot water tank of chemical pulp, mix and thicken part of the mixture of high-concentration filtrate and washing water and slurry, then send it to the drum vacuum pulp washer, and pass through the drum-type vacuum pulp washer. The pulp layer is formed on the net of the vacuum pulp washer, and the mixture of the remaining high-concentration filtrate and washing water is sent to the drum vacuum pulp washer to spray and wash the pulp layer;

[0031] Step 3: Send the mixture of high-concentration filtrate and washing water filtered through the pulp layer in the drum vacuum washer...

Embodiment 3

[0035] A method for treating chemical-mechanical pulp high-concentration filtrate, comprising the steps of:

[0036] Step 1: Send the high-concentration filtrate produced by the chemical-mechanical pulp production line into the chemical pulp hot water tank, add washing water and mix in a ratio of 1:1;

[0037] Step 2: Extract the mixture of high-concentration filtrate and washing water in the hot water tank of chemical pulp, mix and thicken part of the mixture of high-concentration filtrate and washing water and slurry, then send it to the drum vacuum pulp washer, and pass through the drum-type vacuum pulp washer. The pulp layer is formed on the net of the vacuum pulp washer, and the mixture of the remaining high-concentration filtrate and washing water is sent to the drum vacuum pulp washer to spray and wash the pulp layer;

[0038] Step 3: Send the mixture of high-concentration filtrate and washing water filtered through the pulp layer in the drum vacuum washer to the black ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com