A comprehensive simulation test and fault injection platform for turbofan engines for UAVs

A turbofan engine and fault injection technology, applied in electrical testing/monitoring, testing/monitoring control systems, general control systems, etc., can solve problems such as R&D models and supporting guarantee methods that cannot meet the requirements, so as to improve system testing capabilities, The effect of improving autonomy and improving overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the purpose, content and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

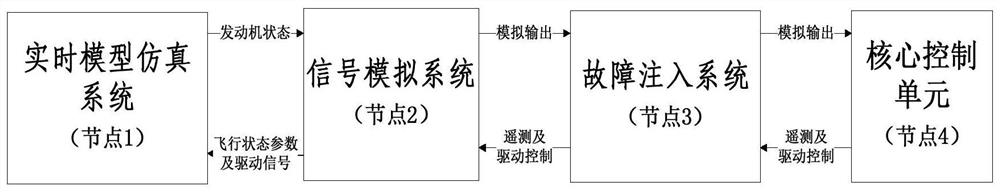

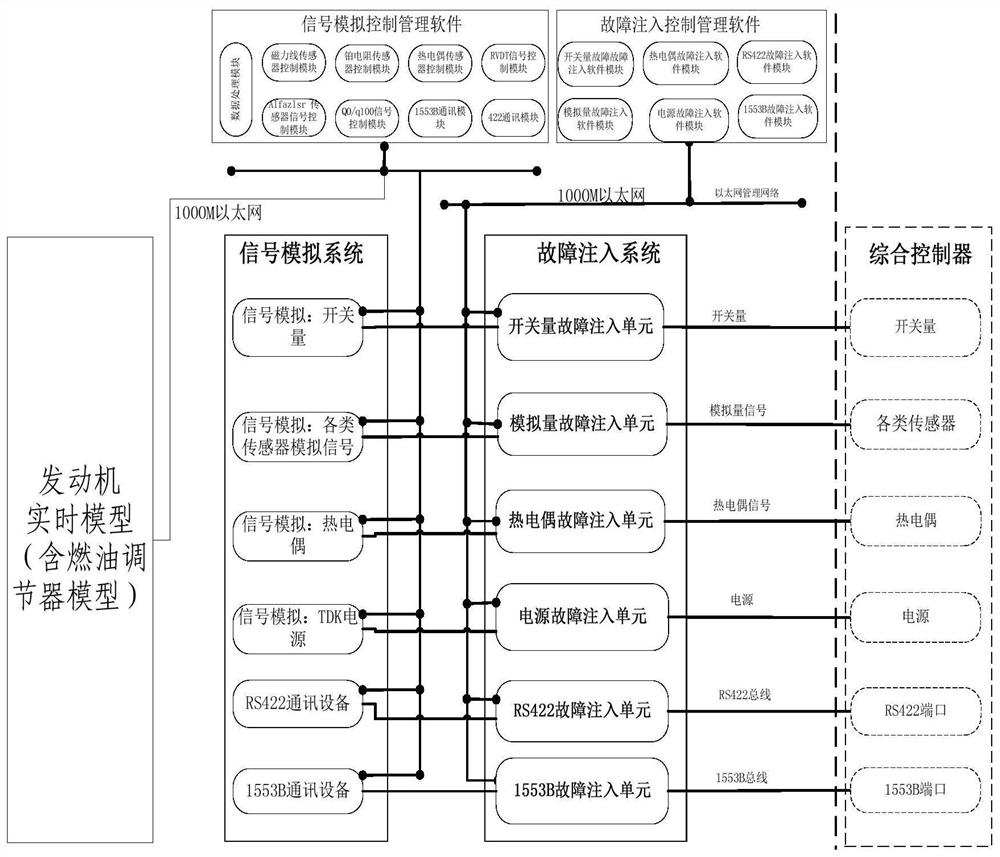

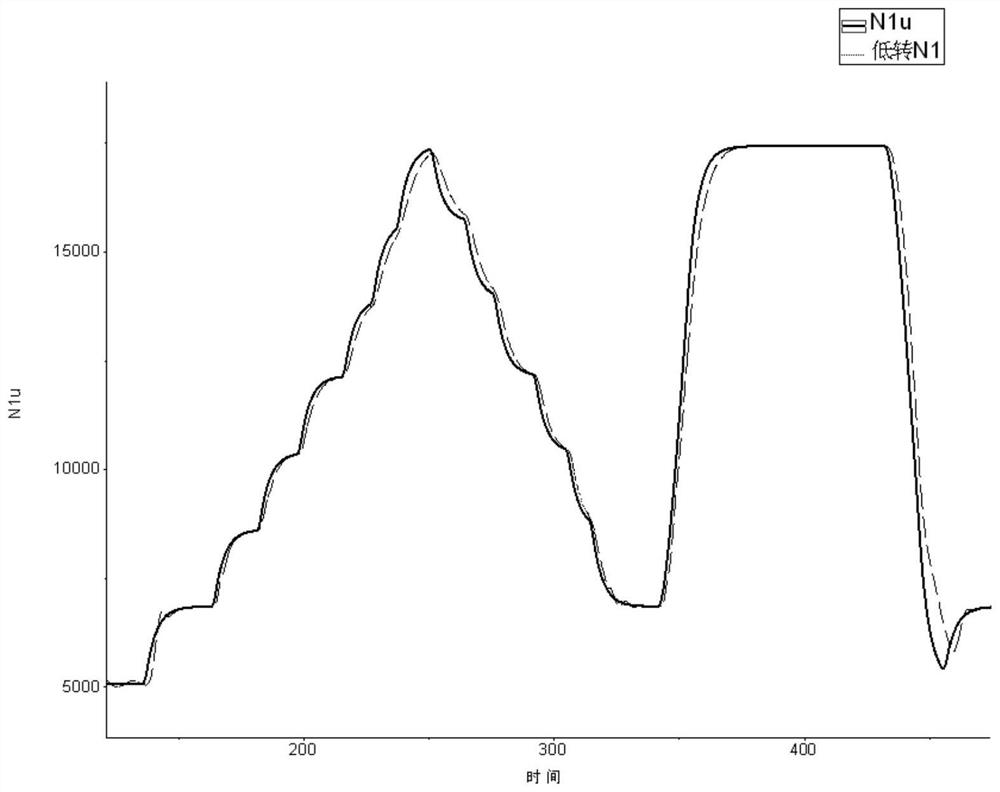

[0026] The comprehensive simulation test and fault injection platform of the turbofan engine for unmanned aerial vehicles of the present invention relies on the high-precision dynamic real-time model to perform full-envelope dynamic and static calculations on the engine system, and performs signal interaction between the engine and the target integrated controller through the interface signal simulation technology. Connect, realize hardware in-loop simulation, simulate the real operation of the engine system to the greatest extent, verify the feasibility of the control law, the stability and control accuracy of the system, and support the control law design and simulation verification of the entire life cycle of the contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com