Chlor-alkali sodium sulfite solution preparation tank and preparation system

A technology of sodium sulfite and chlor-alkali, which is applied in the direction of dissolving, dissolving, driving the agitator to dissolve, etc., can solve the problems of unfavorable system stability, easy fluctuation of adding flow, fluctuation of adding flow of light brine dechlorination, etc., and achieve the effect of regeneration and avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The invention is further illustrated below in conjunction with the accompanying drawings and specific embodiments.

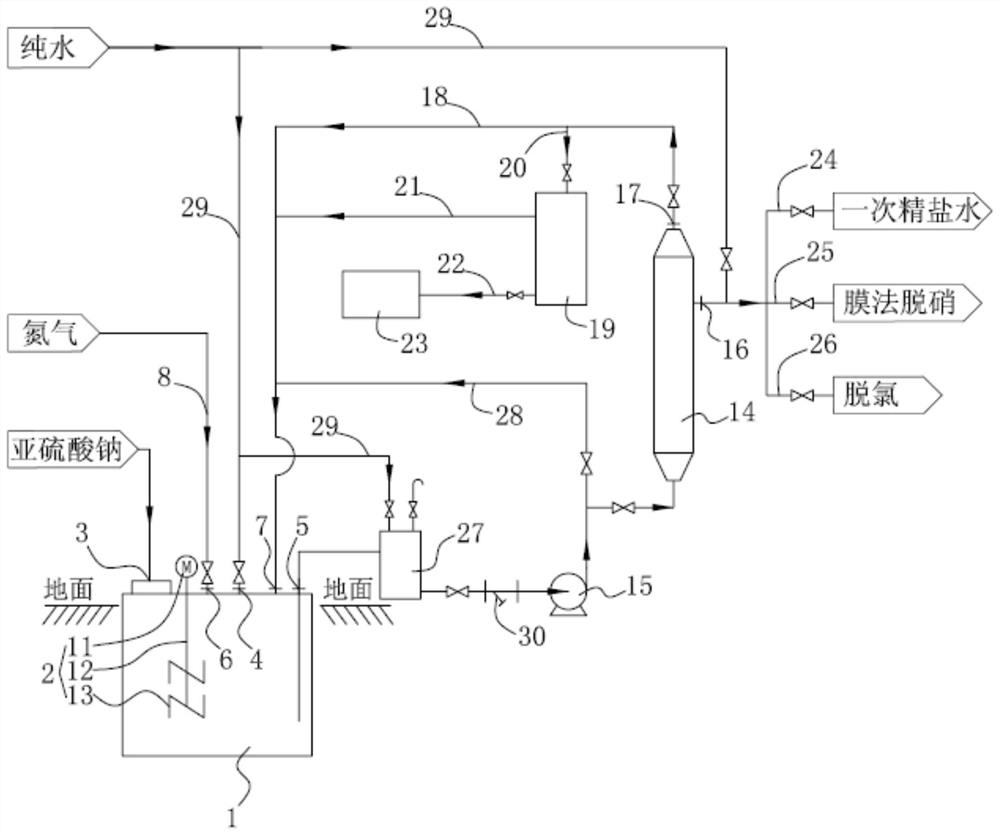

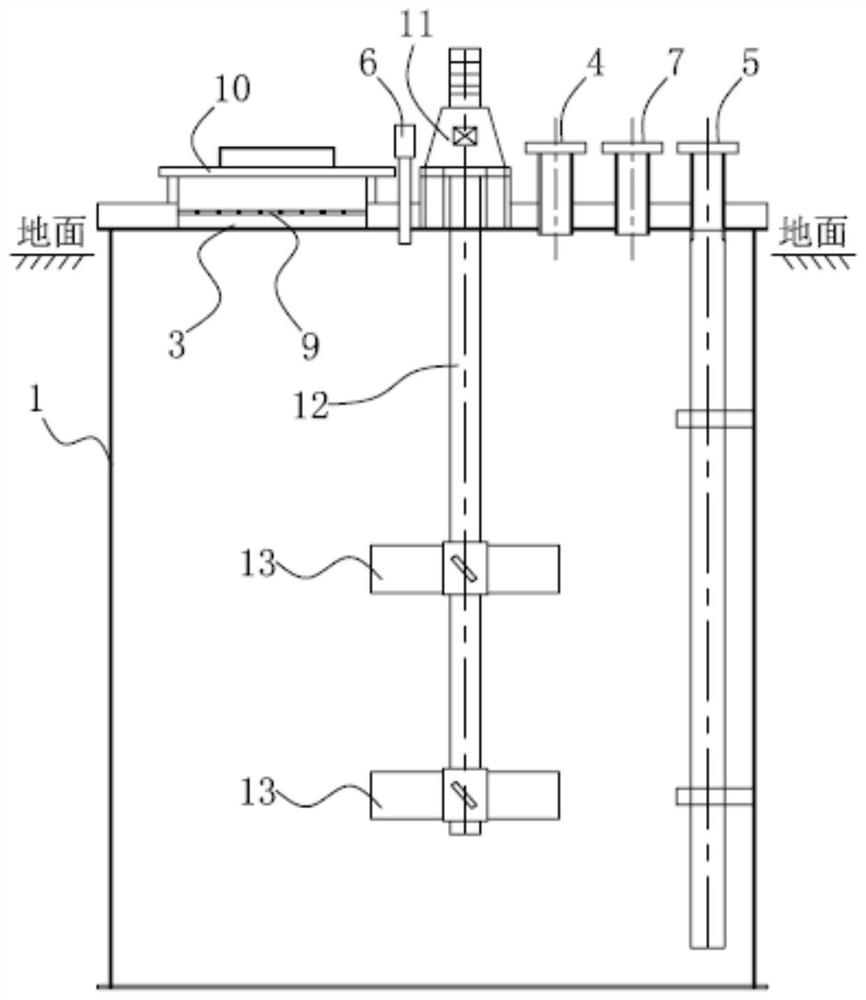

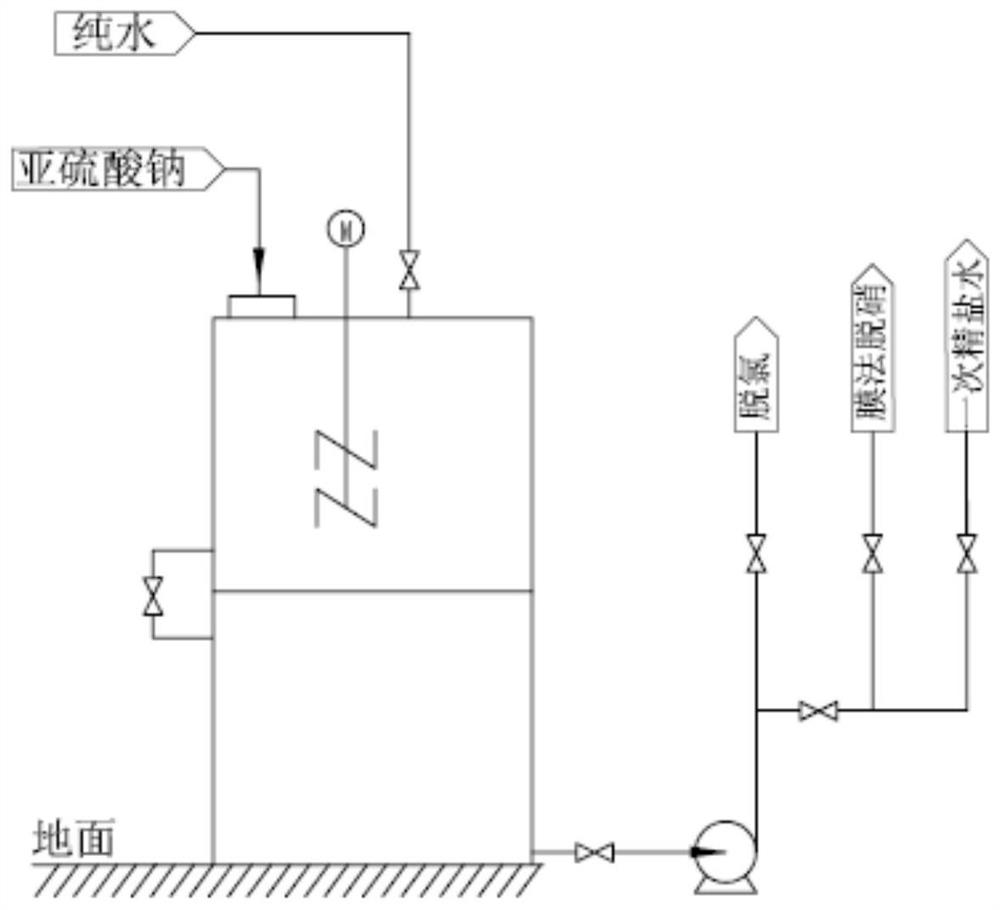

[0028] Such as figure 1 and figure 2 As shown in the present invention, the chlor-alkali of the present invention is formulated with a sodium sulfite, including the formulation of the groove body 1 and the stirring mechanism 2, in the formulation slot body 1, the cavity is disposed, and a feed port 3 is provided on the formulation slot body 1, pure The water feed port 4 and the arrangement liquid outlet port 5 are provided on the formulation slot body 1, and the protective gas connection port 6 can be connected to the air supply line 8 and the protective gas supply device. Configure the protective gas in the cavity.

[0029] When the sodium sodium sodium sulfite solution is performed, the protective gas can be passed through the protective gas connection port 6 to the arrangement cavity in the formation of the groove body 1 to discharge the air in the cavity,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com