Single-component dual-curing-system organosilicon sealant

A dual-curing, silicone technology, used in adhesives, other chemical processes, chemical instruments and methods, etc., can solve the problems of high price, large amount of glue, high cost pressure of enterprises, and achieve good stability and improve adhesion. The effect of sex, guaranteed strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

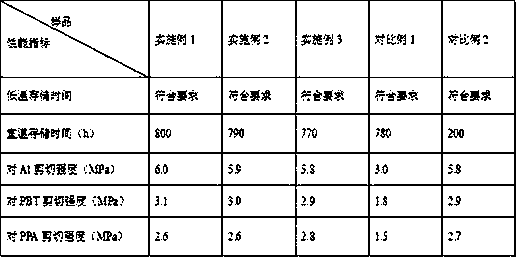

Embodiment 1

[0052] Weigh 38g of methyl vinyl silicone resin as in structural formula (1), where a=1.0, b=0.22; 55g of the above-mentioned rubber base; 1.4g of crosslinking agent as in structural formula (2), with a viscosity of 80mPa.s, where m =0.7, n=1.2, m+n=1.9; 4.5g of adhesive such as structural formula (3), wherein K=7; inhibitor tetramethyldivinyl disiloxane 0.17g; add the above raw materials in sequence, After mixing evenly, lower the temperature of the colloid to room temperature; add 0.38 g of a platinum-vinylsiloxane complex catalyst with a platinum content of 5000 ppm, and mix evenly; then add 0.25 g of bis(2,4-dichlorobenzoyl) peroxide g, mixing evenly to obtain a silicone sealant, which is sealed and stored at room temperature.

Embodiment 2

[0054] Weigh 35g of methyl vinyl silicone resin with structural formula (1), where a=0.9, b=0.20; 50g of the above-mentioned rubber base; 1.3g of crosslinking agent with structural formula (2), viscosity is 50mPa.s, where m =0.6, n=1.4, m+n=2.0; 4.0g of adhesive such as structural formula (3), wherein K=5; inhibitor tetramethyldivinyl disiloxane 0.15g; add the above raw materials in sequence, After mixing evenly, lower the temperature of the colloid to room temperature; add 0.35 g of a platinum-vinylsiloxane complex catalyst with a platinum content of 5000 ppm, and mix evenly; then add 0.20 bis(2,4-dichlorobenzoyl) peroxide g, mixing evenly to obtain a silicone sealant, which is sealed and stored at room temperature.

Embodiment 3

[0056]Weigh 40g of methyl vinyl silicone resin with structural formula (1), where a=1.1, b=0.23; 50g of the above-mentioned rubber base; 1.5g of crosslinking agent with structural formula (2), viscosity is 100mPa.s, where m =0.8, n=1.1, m+n=1.9; 5.0g of adhesive such as structural formula (3), wherein K=8; inhibitor tetramethyldivinyl disiloxane 0.20g; add the above raw materials in sequence, After mixing evenly, lower the temperature of the colloid to room temperature; add 0.40 g of a platinum-vinylsiloxane complex catalyst with a platinum content of 5000 ppm, and mix evenly; then add 0.30 g of bis(2,4-dichlorobenzoyl) peroxide g, mixing evenly to obtain a silicone sealant, which is sealed and stored at room temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com