Connection coupling for the provision of electrical energy, storage system and motor vehicle with connection coupling

A coupling device and storage system technology, applied in the direction of coupling devices, parts of connecting devices, two-part connecting devices, etc., can solve problems such as high current heat loss, achieve small contact resistance, reduce fault sources, and reduce electrical contact resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

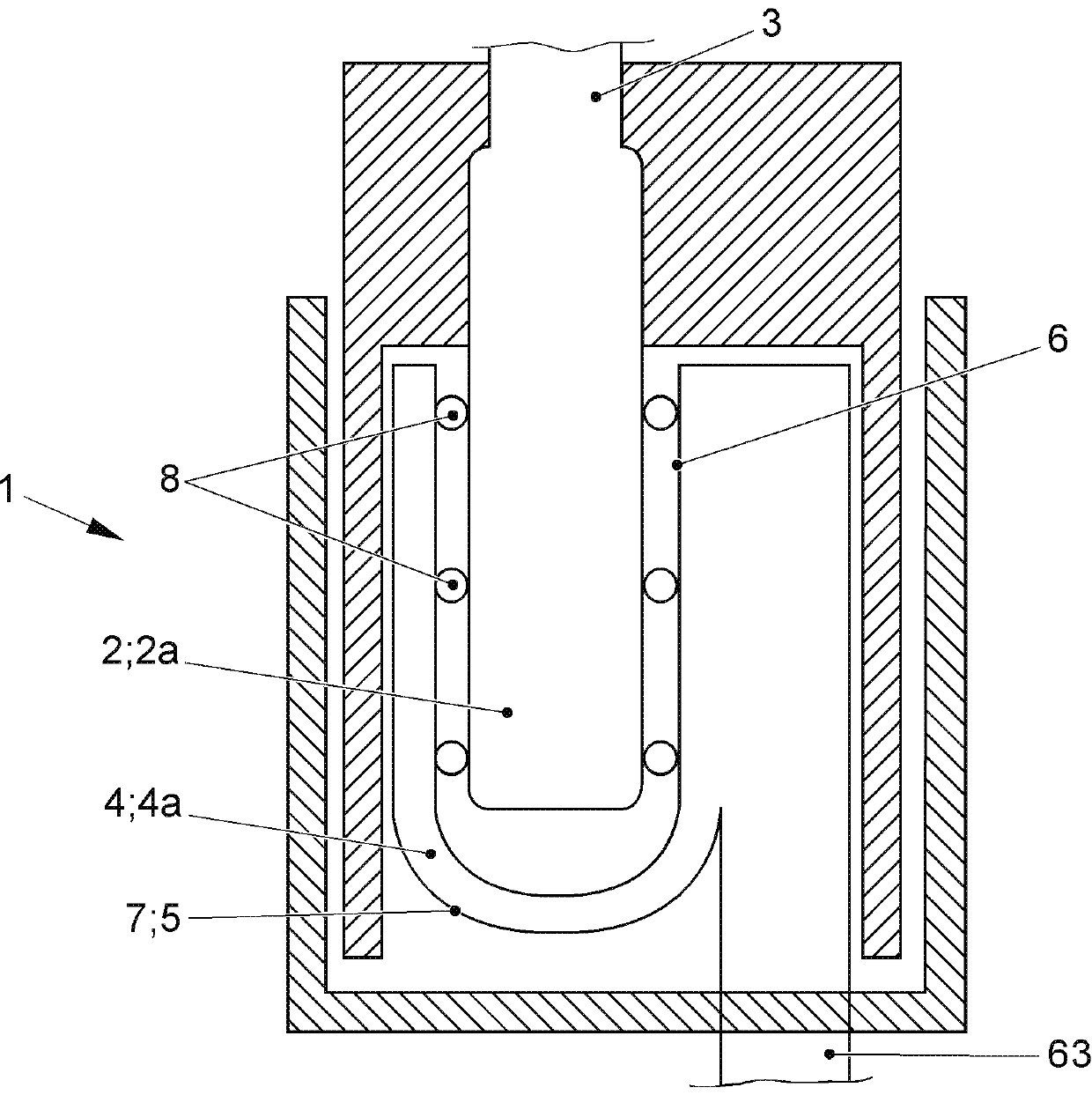

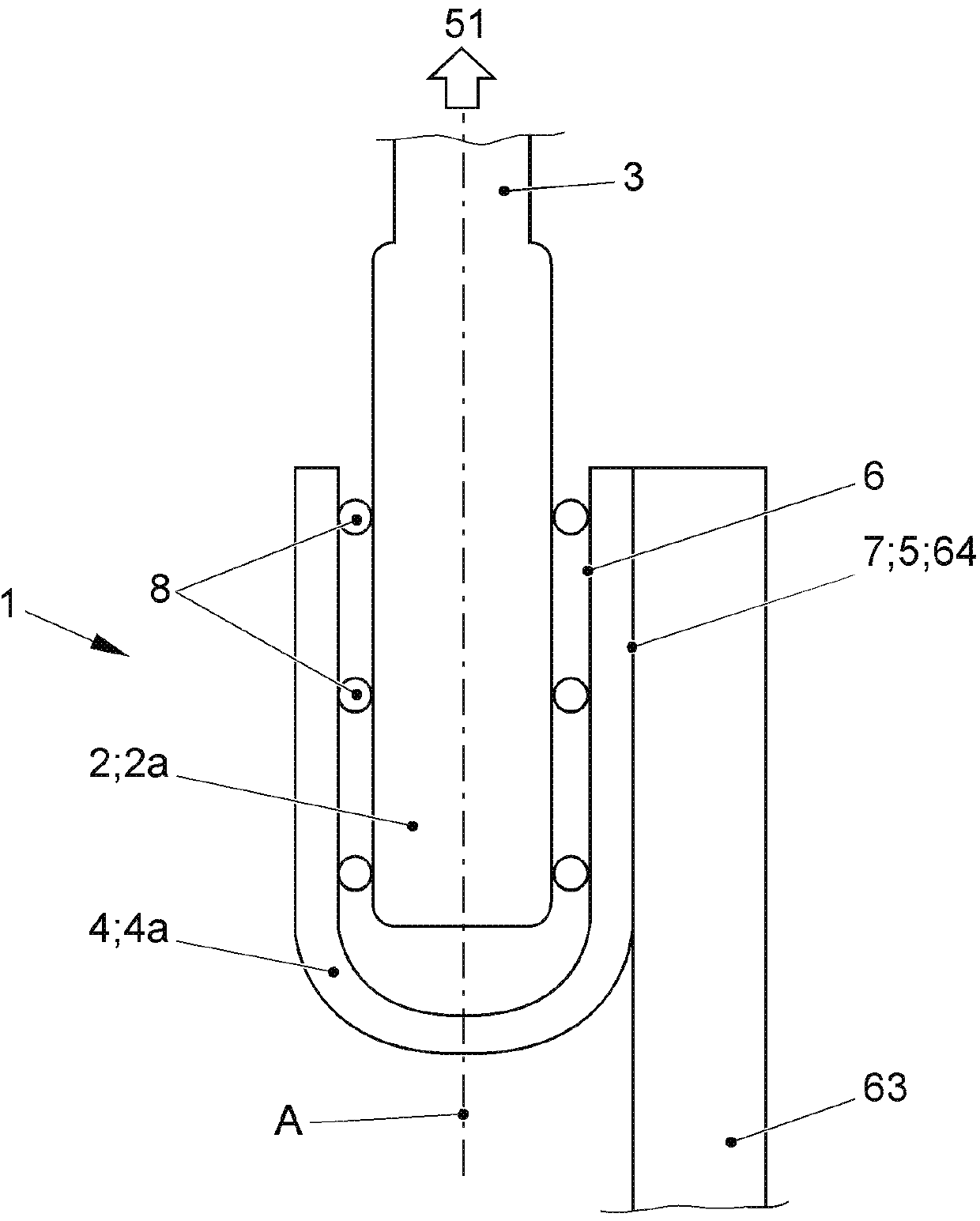

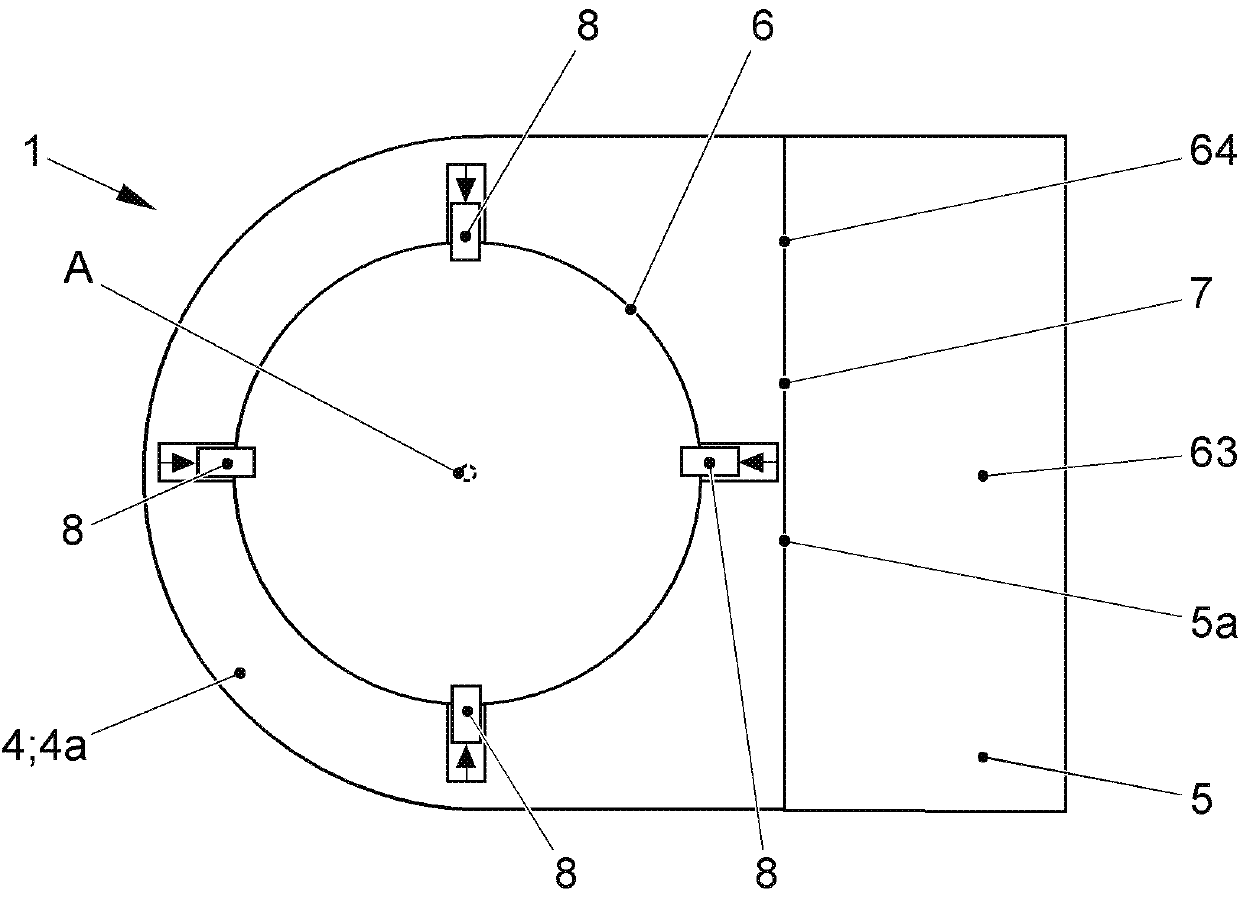

[0055] exist figure 1 A schematic side view of the screwed connection of the module terminal 63 to the cable lug 21 is shown as prior art in . The cable lug 21 establishes an electrically conductive connection to a load system 51 (not shown) of a motor vehicle 50 (not shown). The module terminal 63 establishes an electrically conductive connection to the storage module 60 for electrical energy. The threaded fastener 20 or the screw connection should be implemented vertically for accessibility to the screwing robot in the production line. This results in the necessary bending of the module end 63 and a correspondingly high material requirement for the solution shown. The screw connection clamps the cable lug 21 to the module terminal 63 with a predetermined torque and thus creates an electrically conductive connection. Furthermore, screwed connections should be checked for correct torque over time as screwed connections loosen due to vibration and material movement.

[0056...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com