Fermented feed protein as well as preparation method and application thereof

A technology for fermenting feed and protein is applied in the field of fermented feed protein and its preparation to achieve the effects of improving fermentation efficiency, increasing neutral protease activity and improving nutritional value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

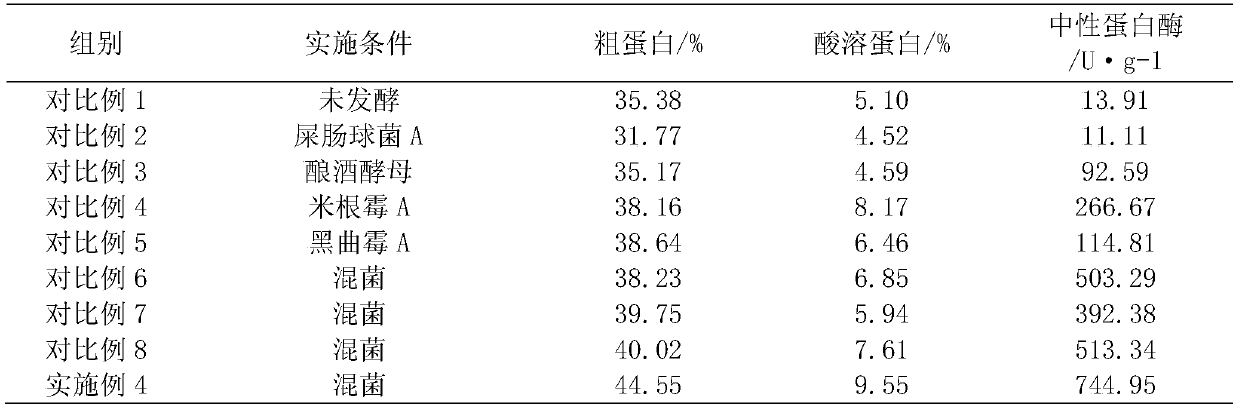

Examples

Embodiment 1

[0068] Take 54 parts by mass of Moringa oleifera seed meal, add 46 parts by mass of water, inoculate 16 parts by mass of mixed bacteria of Rhizopus oryzae A and Aspergillus niger A (the ratio is 1:1 by mass), ferment at 30°C, and ferment in a sealed container for 38 hours; then inoculate excrement 8 parts by mass of Enterococcus A, mixed evenly, fermented at 30° C., sealed and fermented for 34 hours. The crude protein content, acid soluble protein content and neutral protease activity of the feed protein prepared by the above method are 40.61%, 9.34% and 752.35U / g respectively.

Embodiment 2

[0070] Take 75 parts by mass of Moringa oleifera seed meal, add 25 parts by mass of water, inoculate 14 parts by mass of mixed bacteria of Rhizopus oryzae A and Aspergillus niger A (the ratio is 1:1 by mass), ferment at 30°C, and ferment in a sealed container for 40 hours; then inoculate excrement 6 parts by mass of Enterococcus A, mixed uniformly, fermented at 30° C., sealed and fermented for 32 hours. The crude protein content, acid-soluble protein content and neutral protease activity of the feed protein prepared by the above method are 41.88%, 9.64% and 849.74U / g respectively.

Embodiment 3

[0072] Take 50 parts by mass of Moringa oleifera seed meal, add 50 parts by mass of water, inoculate 13 parts by mass of Rhizopus oryzae A and Aspergillus niger A mixed bacteria (ratio: 1:1 by mass), ferment at 30°C, and ferment in a sealed container for 36 hours; then inoculate excrement 7 parts by mass of Enterococcus A, mixed evenly, fermented at 30° C., sealed and fermented for 36 hours. The crude protein content, acid-soluble protein content and neutral protease activity of the feed protein prepared by the above method are 46.78%, 10.64% and 711.93U / g respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com