Instant powder hollow granulation device and granulation process

A granulation device, the technology of instant powder, which is applied in the direction of making medicine into special physical or taking form, dividing liquid into bead drop granulation, tea, etc., can solve the problem of different particle size, poor tea powder, and finished product. It can save production costs, have good size uniformity, and improve solubility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

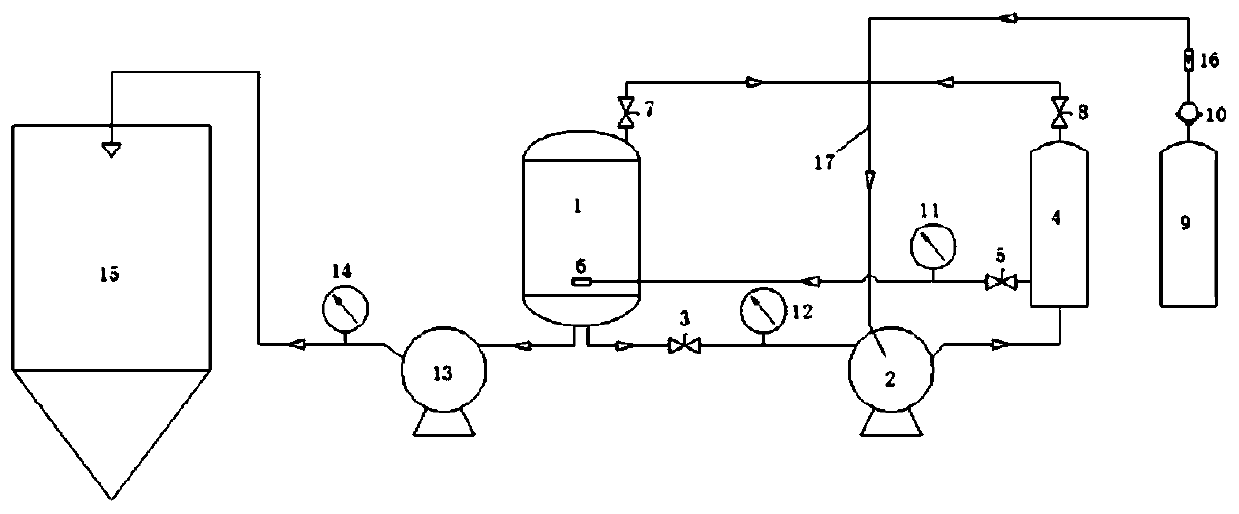

[0031] Such as figure 1 As shown, a hollow granulation device for instant powder in this embodiment includes a concentrated liquid sealed storage tank 1 and a carbon dioxide storage tank 9, the concentrated liquid sealed storage tank 1 is connected to the gas-liquid separation tank 4 through the gas-liquid mixing pump 2, and the carbon dioxide storage tank The tank 9 is connected to the gas-liquid mixing pump 2, the gas-liquid separation tank 4 is connected to the gas diffuser 6 in the concentrated liquid sealed storage tank 1, the concentrated liquid sealed storage tank 1 is connected to the plunger pump 13, and the plunger pump 13 is connected to the spray drying tower 15; A feed valve 3 and a vacuum gauge 12 are sequentially installed on the pipeline between the concentrated liquid sealed storage tank 1 and the gas-liquid mixing pump 2; A pressure relief valve 10 and a flow meter 16; a pressure regulating valve 5 is installed on the pipeline between the gas-liquid separatio...

Embodiment 2

[0052] The difference between the instant powder hollow granulation device of the present embodiment and embodiment one is:

[0053] The carbon dioxide gas in the carbon dioxide storage tank can also be an inert gas that is allowed to be used in food such as nitrogen. Can be selected according to needs, good adaptability.

[0054] Other structures can refer to Embodiment 1.

Embodiment 3

[0056] The difference between the instant powder hollow granulation process of the present embodiment and embodiment one is:

[0057] The control of the specific gravity and particle size of the hollow particle product is realized by changing the concentration of the concentrated solution. The greater the concentration, the greater the specific gravity and the corresponding increase in particle size. Wherein, the concentration range of the concentrate is between 15% and 50%.

[0058] For other process steps, reference may be made to Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com