A sorting-grade pre-selection and tailings throwing process for extremely lean hematite

A hematite and granulation technology, applied in the direction of solid separation, magnetic separation, chemical instruments and methods, etc., can solve the problem of semi-autogenous mill stubborn stone accumulation, etc., to reduce the cycle load, reduce the cycle load, optimize effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with drawings and embodiments.

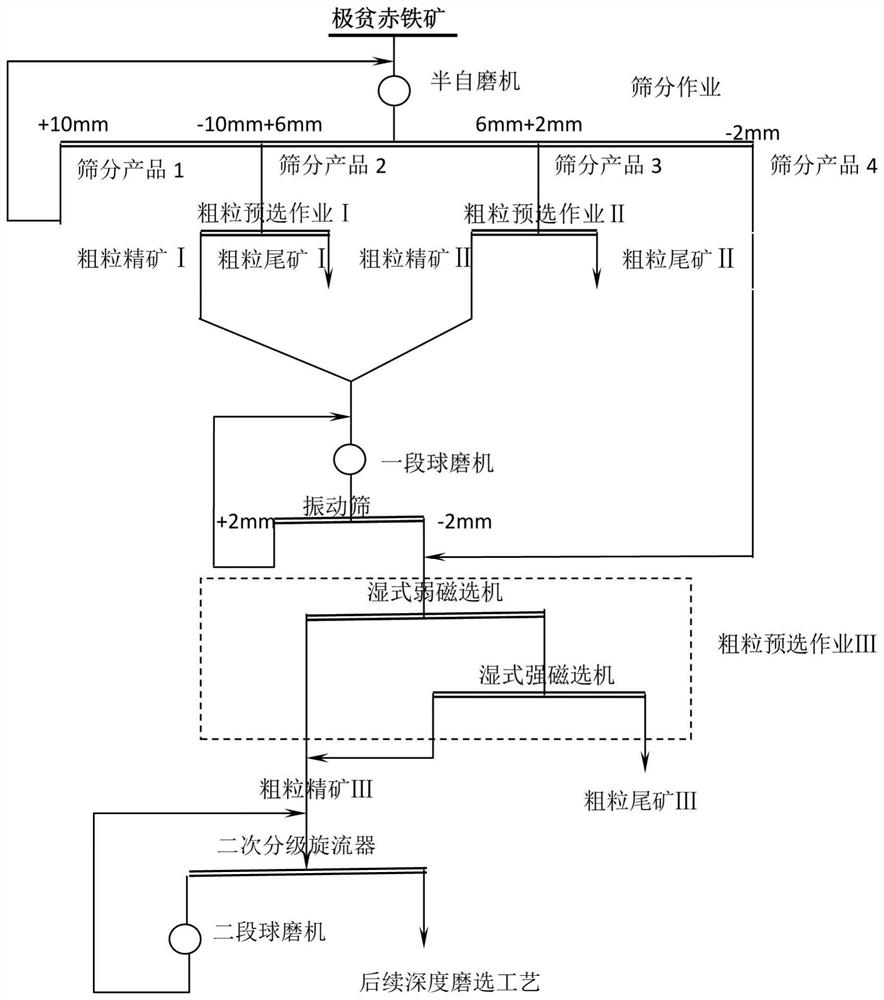

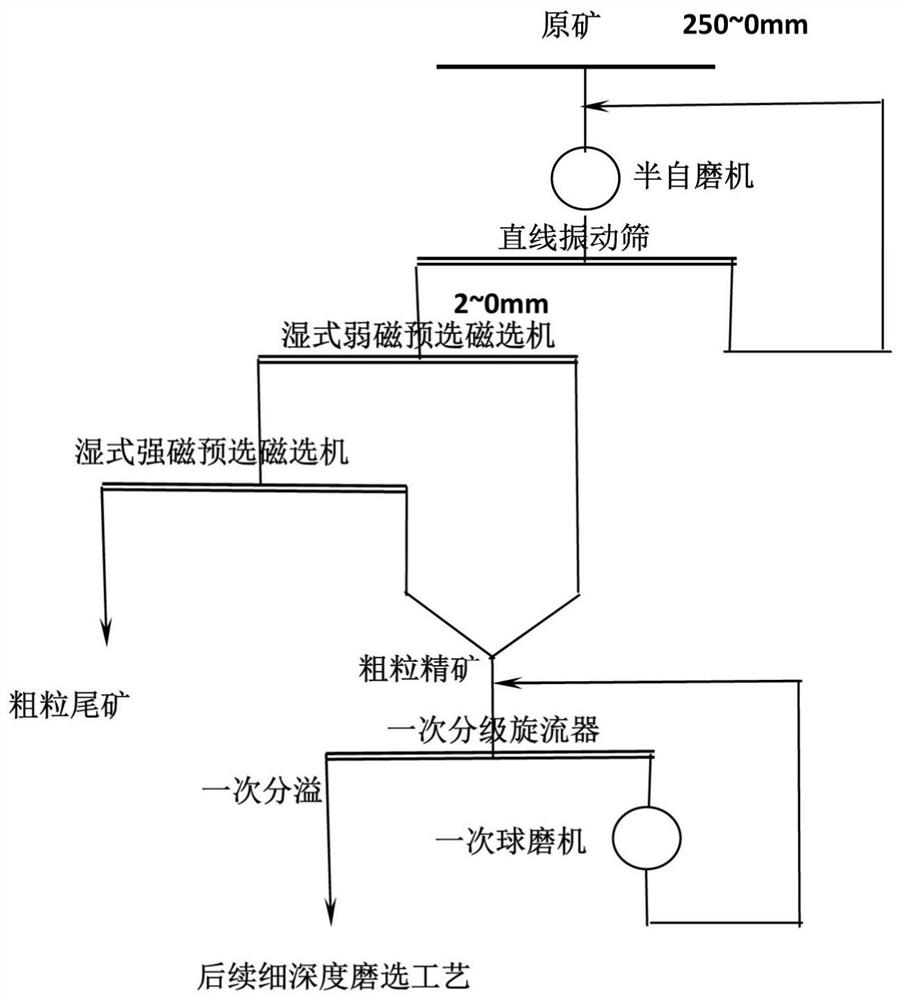

[0023] like figure 1 As shown, a kind of ultra-poor hematite pre-selection and tailings throwing process of the present invention includes feeding the ultra-poor hematite with a particle size of 250-0 mm and a grade of 18% into the wet semi-autogenous grinding operation , the semi-autogenous grinding operation uses a Φ9.15×5.03m wet semi-autogenous mill to obtain a wet semi-autogenous mill discharge product with a particle size of 14-0 mm, which is characterized in that it also includes screening operations and coarse grain pre-selection operations Ⅰ , coarse-grain pre-selection operation II, one-stage closed-circuit grinding operation, coarse-grain pre-selection operation III and second-stage closed-circuit grinding operation;

[0024] The screening operation deals with the ore discharge products of the wet semi-autogenous grinding operation, and four screening produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com