Silver powder production method capable of controlling sintering activity

A production method and sintering activity technology, which is applied in the field of solar cells, can solve the problems of unfavorable slurry rapid sintering process and high powder sintering temperature, and achieve the effect of easy operation, simple process and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1. Prepare 15% dilute sulfuric acid solution.

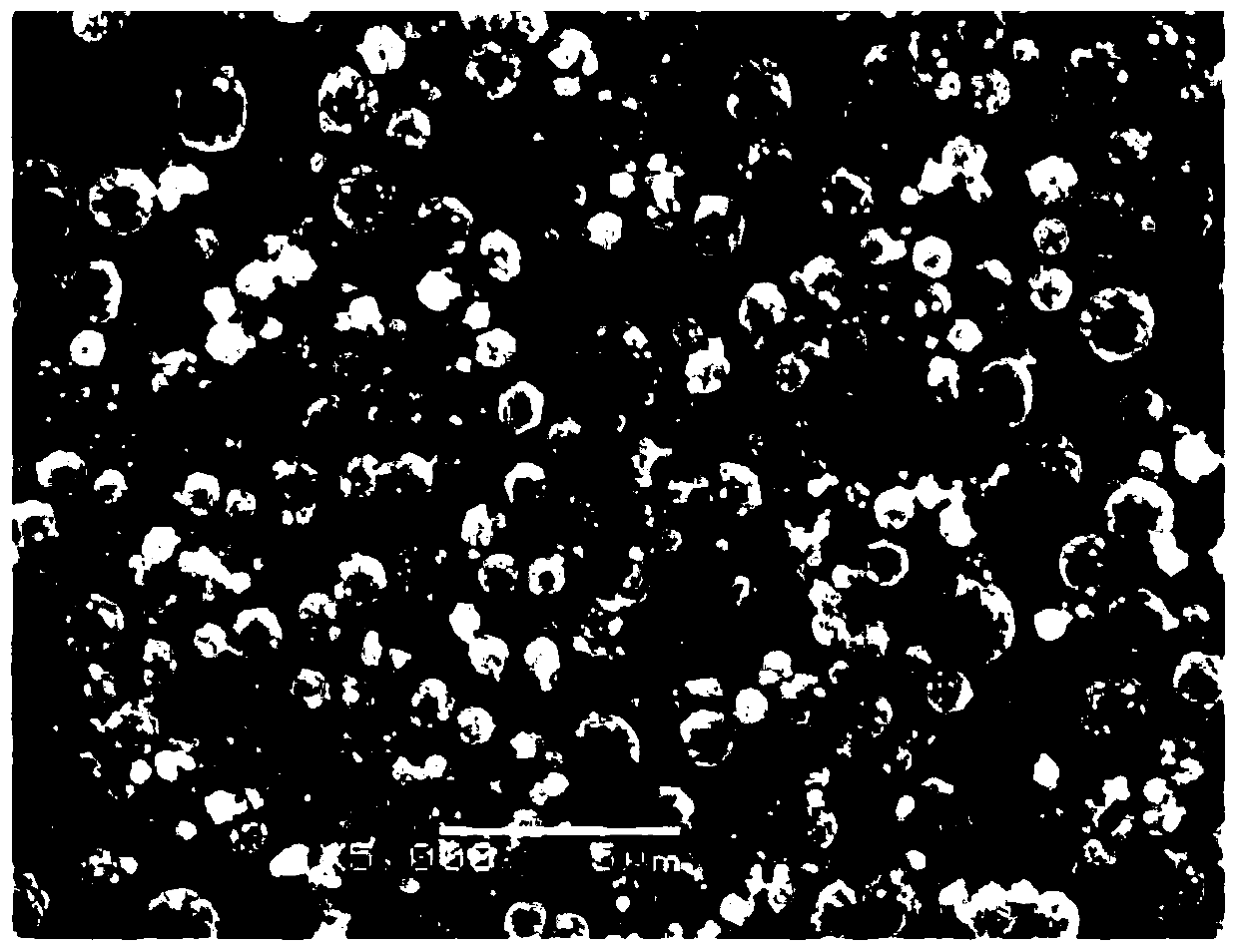

[0031] 2. Activation of silver powder: Take 60g of 0.5μm silver powder in a 500ml beaker, add 300ml of 5% dilute sulfuric acid solution, stir ultrasonically for 25 minutes, let it stand, pour off the supernatant, wash it once with 300ml of deionized water, and then Wash once with 300ml dilute sulfuric acid solution, and finally wash with deionized water until neutral.

[0032] 3. Preparation of reducing solution: Weigh 0.57g of ascorbic acid and 2g of potassium borohydride into a 500ml beaker, add 300ml of deionized water to dissolve, and boil for 5-10min.

[0033] 4. Prepare silver ammonia solution: Weigh 21g of silver nitrate into a 500ml beaker, add 400ml of deionized water to dissolve, add ammonia water dropwise until the solution is transparent. Weigh 8g of sodium hydroxide and dissolve it in 200ml of deionized water, slowly add the sodium hydroxide solution into the silver ammonia solution, if precipitation occurs, ...

Embodiment 2

[0037] 1. Prepare 5% dilute sulfuric acid solution.

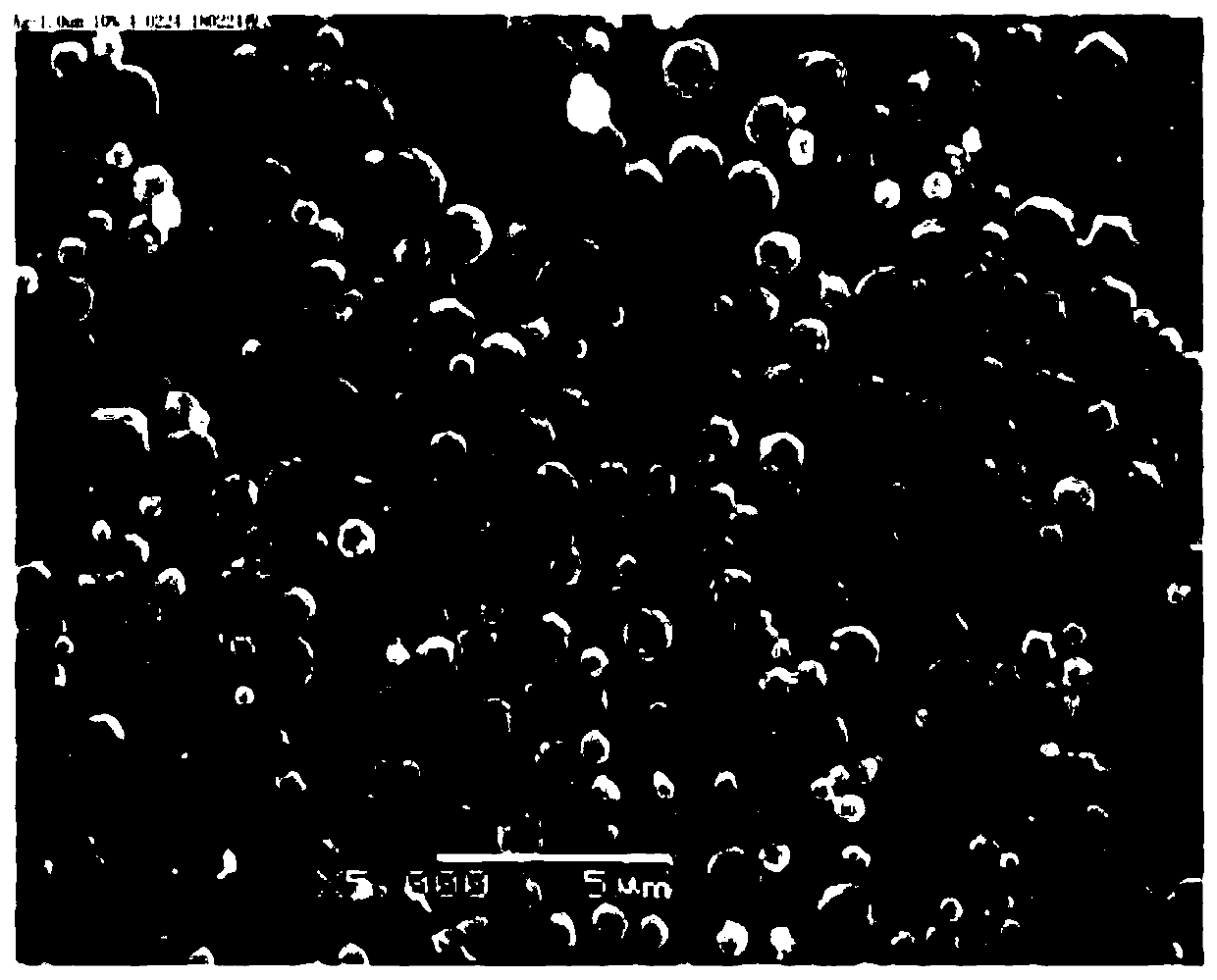

[0038] 2. Activation of silver powder: Take 60g of 5.0μm silver powder in a 500ml beaker, add 300ml of a mixed solution of 5% dilute sulfuric acid and OP-10, stir ultrasonically for 25 minutes, let it stand, pour off the supernatant, and then use 300ml of deionized water Wash to neutral.

[0039] 3. Preparation of reducing solution: Weigh 7g of potassium borohydride into a 500ml beaker, add 300ml of deionized water to dissolve, and boil for 5-10min.

[0040] 4. Preparation of silver ammonia solution: Weigh 4.71g of silver nitrate into a 250ml beaker, add 90ml of deionized water to dissolve, add ammonia water dropwise until the solution is transparent. Weigh 2g of sodium hydroxide and dissolve it in 70ml of deionized water, slowly add the sodium hydroxide solution into the silver ammonia solution, if precipitation occurs, add ammonia water to dissolve.

[0041] 5. Preparation of silver-coated powder: add the activated silv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com