Ordered porous carbon electrode material and preparation method thereof

A porous carbon electrode and composite carbon technology, which is applied in hybrid capacitor electrodes, hybrid/electric double layer capacitor manufacturing, nanotechnology for materials and surface science, etc., can solve the problem of long time-consuming physical activation, high energy consumption of chemical activation, No pollution and other problems, to achieve the effect of simple preparation method, good electrochemical performance and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

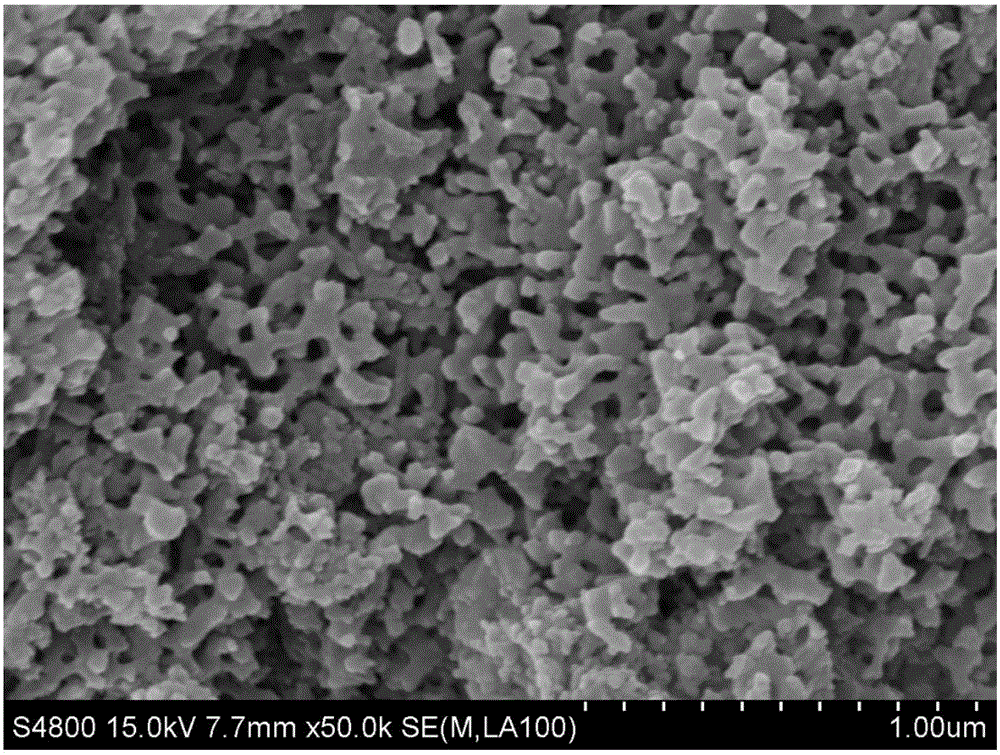

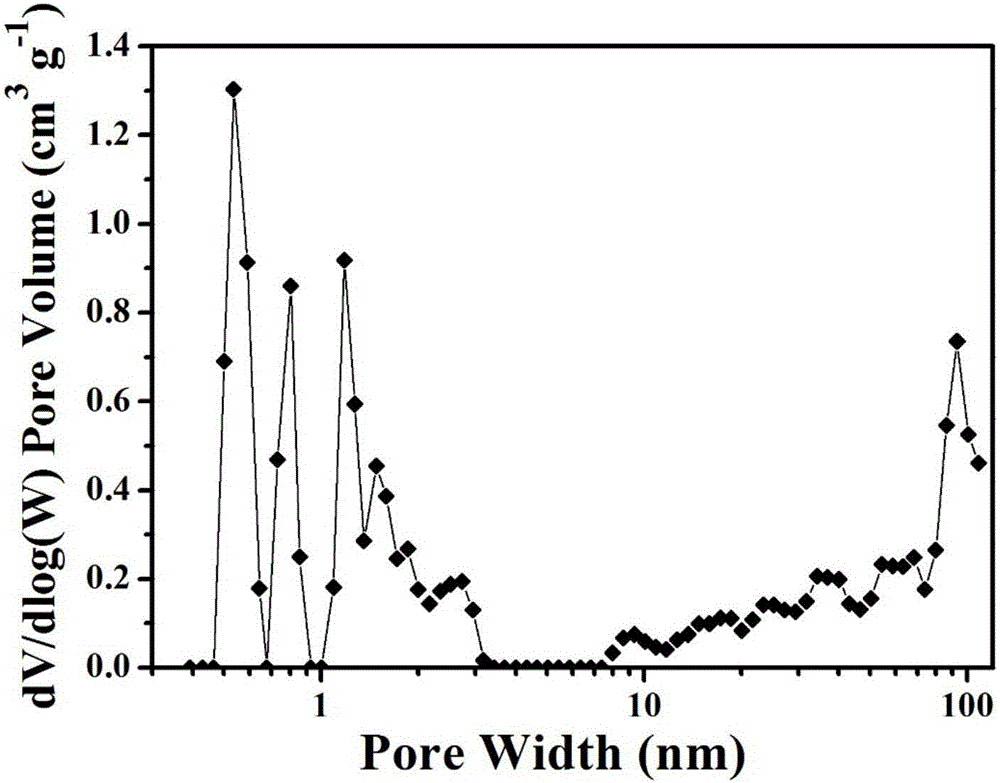

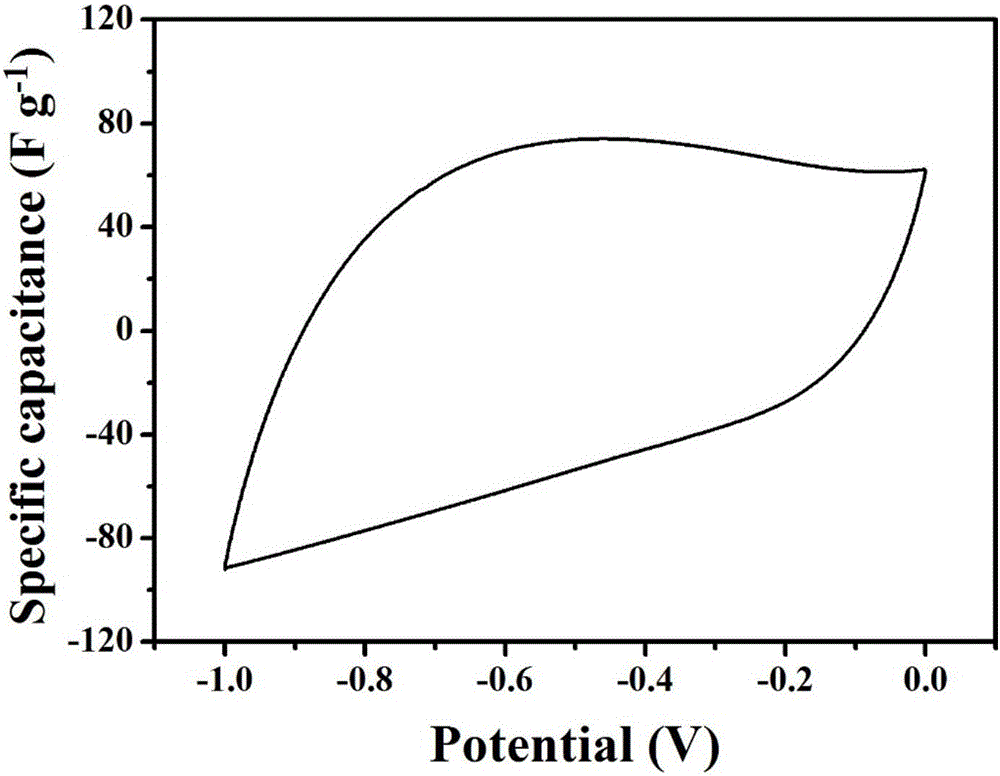

[0030] Weigh 8.0 g of ethylenediaminetetraacetic acid tripotassium salt (EDTA-3K) and dissolve it in 4 g of deionized water, oscillate fully and ultrasonically dissolve. Then add 0.8g porous silicon KIT-6 template agent (KIT-6:EDTA-3K mass ratio is 0.1:1), so that the template agent is fully immersed in the EDTA-3K solution, soaked for 8h, then ultrasonicated for 2h, and vacuumed for 6h Afterwards, the mixture was centrifuged at 4500 r / min for 2 h to extract the sediment, which was dried at 80° C. to obtain a dry product.

[0031] Then put the above-mentioned composite product after drying into a nickel crucible, place it in a high-temperature quartz tube furnace, and 2 (Flow rate: 100mL / min), the temperature was raised to 700°C at a heating rate of 2°C / min, maintained at 700°C for 3 hours, cooled naturally, and a black composite carbon material was obtained after pyrolysis. Then add excess 5% HF (v / v) solution to immerse the composite carbon material, stir for 24h, and separ...

Embodiment 2

[0034] Weigh 8.0 g of ethylenediaminetetraacetic acid dipotassium salt (EDTA-2K) and dissolve it in 16 g of deionized water, oscillate fully and ultrasonically dissolve. Then add 2.0g porous silicon KIT-6 template agent (KIT-6:EDTA-2K mass ratio is 0.25:1), so that the template agent is fully immersed in the EDTA-2K solution, soaked for 4h, then ultrasonic 0.5h, vacuum 3h After the treatment, the mixture was centrifuged at 2500 r / min for 4 h to extract the sediment, which was dried at 60° C. to obtain a dry product.

[0035] Then put the above-mentioned composite product after drying into a nickel crucible, place it in a high-temperature quartz tube furnace, and under the protection of the inert gas flow Ar (flow rate is 20mL / min), heat up to 900°C at a heating rate of 10°C / min. After maintaining at 900°C for 0.5h, it was cooled naturally, and a black composite carbon material was obtained after pyrolysis.

[0036] Then add an excess of 20% HF (v / v) solution to immerse the co...

Embodiment 3

[0039] Weigh 8.0 g of ethylenediaminetetraacetic acid dipotassium salt (EDTA-2K) and dissolve it in 10 g of deionized water, oscillate fully and ultrasonically dissolve. Then add 1.0g of porous silicon KIT-6 template agent (KIT-6:EDTA-2K mass ratio is 0.125:1), so that the template agent is fully immersed in the EDTA-2K solution, soaked for 6h, then ultrasonicated for 1h, and vacuumed for 5h Afterwards, the mixture was centrifuged at 3500 r / min for 3 h to extract the sediment, which was dried at 70° C. to obtain a dry product.

[0040] Then put the above-mentioned composite product after drying into a nickel crucible, place it in a high-temperature quartz tube furnace, and under the protection of the inert gas flow Ar (flow rate is 60mL / min), heat up to 800°C at a heating rate of 6°C / min. After maintaining at 800°C for 2 hours, it was cooled naturally, and a black composite carbon material was obtained after pyrolysis.

[0041] Then add an excess of 10% HF (v / v) solution to i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com