A method and product thereof for preparing scandium-containing aluminum alloy parts by 3D printing

A scandium-aluminum alloy, 3D printing technology, applied in the direction of additive manufacturing, process efficiency improvement, additive processing, etc., can solve the problems of strength, toughness, plasticity, high temperature performance, corrosion resistance and geometric characteristics, and reduce stress. Corrosion cracking tendency, optimization of quenching time, effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

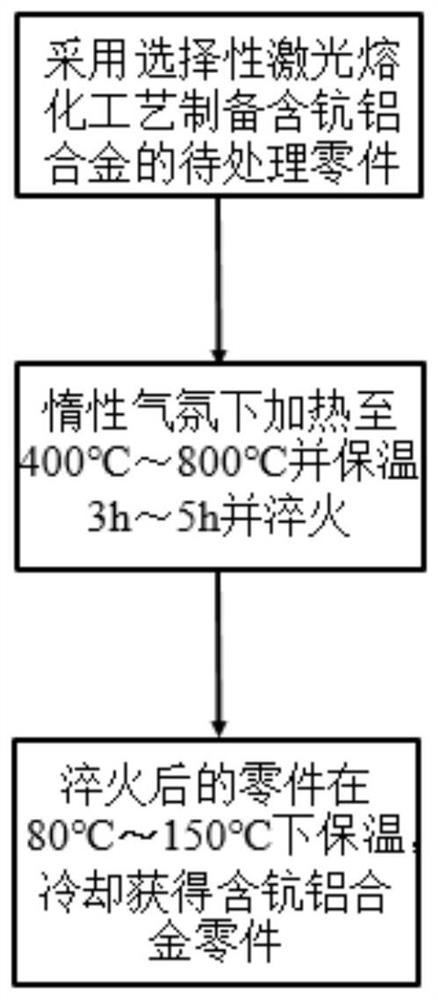

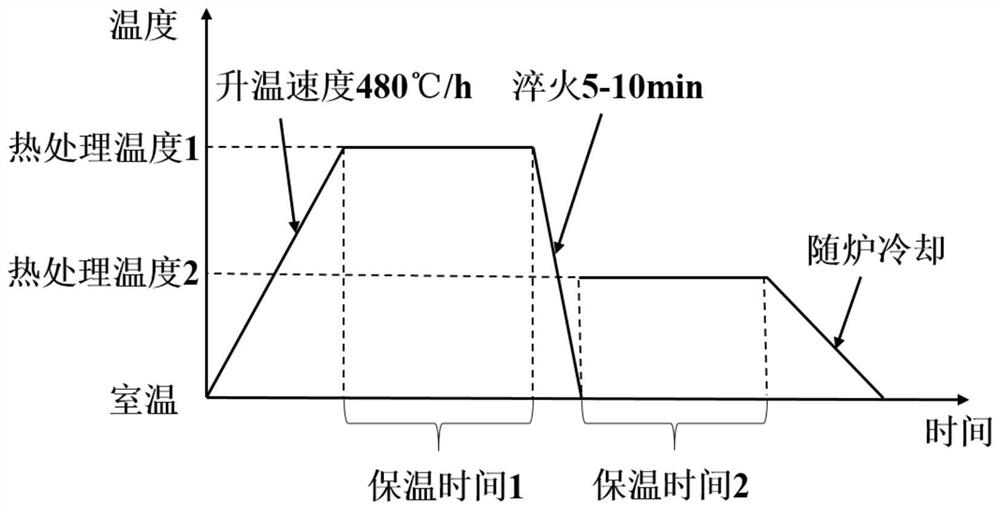

[0031] (a) Prepare scandium-containing aluminum alloy parts to be processed by selective laser melting process, which includes the following components, Mg: 4%, Ag: 0.8%, Mn: 0.5%, Zr: 0.1%, Zn: 1.0%, Ti: 0.05%, Sc: 0.2%, the balance is Al;

[0032] (b) Put the scandium-containing aluminum alloy in a high-temperature box-type furnace, raise the temperature of the high-temperature box-type furnace to 400°C at a heating rate of 480°C / h under an inert atmosphere and keep it for 4 hours, and then transfer it to water within 10s~20s Quenching for 5 minutes;

[0033] (c) keeping the quenched parts at 100° C. for 4 hours, and then cooling to room temperature, so as to obtain scandium-containing aluminum alloy parts.

Embodiment 2

[0035] (a) Prepare scandium-containing aluminum alloy parts to be processed by selective laser melting process, which includes the following components, Mg: 4.5%, Ag: 0.3%, Mn: 0.1%, Zr: 0.3%, Zn: 0.4%, Ti: 0.01%, Sc: 0.15%, the balance is Al;

[0036] (b) Put the scandium-containing aluminum alloy in a high-temperature box-type furnace, raise the temperature of the high-temperature box-type furnace to 800°C at a heating rate of 480°C / h under an inert atmosphere and keep it warm for 3 hours, and then transfer it to water within 10s~20s Quenching for 10min;

[0037] (c) keeping the quenched parts at 80° C. for 5 hours, and then cooling to room temperature, so as to obtain scandium-containing aluminum alloy parts.

Embodiment 3

[0039] (a) Prepare scandium-containing aluminum alloy parts to be treated by selective laser melting process, which includes the following components, Mg: 5.0%, Ag: 1.5%, Mn: 0.6%, Zr: 0.2%, Zn: 0.7%, Ti: 0.08%, Sc: 0.05%, the balance is Al;

[0040] (b) Put the scandium-containing aluminum alloy in a high-temperature box-type furnace, raise the temperature of the high-temperature box-type furnace to 600°C at a heating rate of 480°C / h under an inert atmosphere and keep it warm for 5h, and then transfer it to water within 10s~20s Quenching 8min;

[0041](c) keeping the quenched parts at 150° C. for 8 hours, and then cooling to room temperature, so as to obtain scandium-containing aluminum alloy parts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com