Large alloy steel forge piece water cooling quenching tempering technology

A technology of quenching and tempering, alloy steel, applied in the field of forging processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

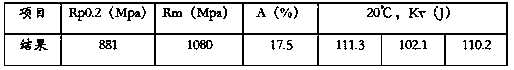

Examples

Embodiment 1

[0088] Water-cooled quenching and tempering treatment of φ6970 / φ6360×430 ring forgings made of 42CrMo:

[0089] 1. Blanking: Select 43 tons of 42CrMo refined steel ingots for blanking, and remove nozzles and risers;

[0090] 2. Forging and forming: heating and forging the blank;

[0091] 3. Heat treatment after forging: After cooling the forging to room temperature in air, put it into a heat treatment furnace with a furnace temperature not higher than 300°C, raise the temperature to 650°C at a speed of ≤120°C / h, and keep it for 3.0h; then heat it up to 880°C, keep warm for 8.0h, and air cool to room temperature after the heat preservation is over;

[0092] 4. Rough turning: According to the shape and size of the finished forging and forging blank, the machining allowance of each part is determined to ensure that after quenching and tempering, the size of each part of the forging can meet the size requirements of the finished product;

[0093] 5. Ultrasonic testing (UT): Carr...

Embodiment 2

[0103] Ring rolling machine 5CrNiMo cone roller water cooling quenching and tempering treatment:

[0104] 1. Blanking: Select 69 tons of refined steel ingots made of 5CrNiMo;

[0105] 2. Forging and forming: heating and forging the steel ingot, eagerly cutting the nozzle and riser;

[0106] 3. Heat treatment after forging: put the forged conical roller into the heat treatment furnace when it cools down to about 650°C on the surface, and then set the furnace temperature at 650°C and keep it warm for 8.0h; Power up to 880°C, hold for 35 hours, and air-cool after leaving the furnace; when the surface temperature is about 300°C, put it into a heat treatment furnace, set the furnace temperature to 300°C, hold for 3.0h, then heat up to 650°C at ≤80°C / h, and hold 40.0h, out of the oven and air-cooled;

[0107] 4. Rough turning: According to the finished size of the tapered roller and the size of the forging after normalizing + tempering, draw the sawing lines at both ends and imple...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com