A kind of cooling method of titanium alloy ingot

A cooling method and titanium alloy technology, which is applied in the field of cooling titanium alloy ingots, can solve the problems of low cooling efficiency, high production cost, and difficulty in controlling the oxidation of the ingot head

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

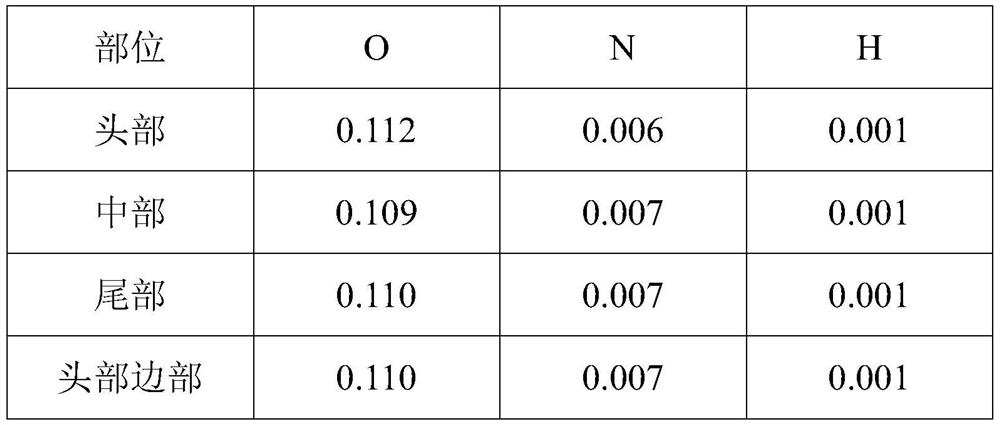

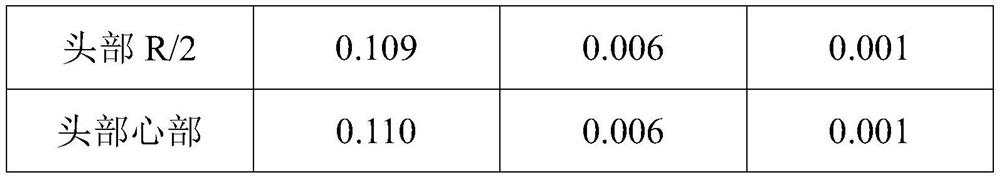

Embodiment 1

[0023] Step 1. Connect the argon gas bottle with the argon-filled cooling pipe before arcing and smelting the ingot with a specification of Φ560mm and a feeding capacity of 1800kg to ensure that the argon gas purity inside the argon gas bottle is not lower than 99.99%, and the air pressure is not lower than 1MPa. And ensure that there is no leakage point at the pipe connection, close the flow control valve of the argon gas cylinder, open the vacuum system valve of the vacuum consumable electric arc furnace, adjust the vacuum pressure in the vacuum consumable electric arc furnace to ≤2.0Pa, and the leak rate to ≤1.0Pa / min After that, turn on the circulating cooling water and start the arc to melt the ingot;

[0024] Step 2. After the ingot is smelted and tripped, adjust the inlet water temperature of the melting station to 30°C and the outlet water temperature to 40°C to ensure that the cooling water flow is at 1000L / min, and keep the vacuum system open to maintain the vacuum se...

Embodiment 2

[0034] Step 1. Connect the argon gas bottle with the argon-filled cooling pipe before arcing and smelting the ingot with a specification of Φ560mm and a feeding capacity of 1800kg to ensure that the argon gas purity inside the argon gas bottle is not lower than 99.99%, and the air pressure is not lower than 2.5MPa , and ensure that there are no leaks at the pipeline connection, close the flow control valve of the argon gas cylinder, open the vacuum system valve of the vacuum consumable electric arc furnace, adjust the vacuum pressure in the vacuum consumable electric arc furnace to ≤2.0Pa, and the leak rate to ≤1.0Pa / After min, turn on the circulating cooling water, and start the arc to melt the ingot;

[0035] Step 2. After the ingot is smelted and tripped, adjust the inlet water temperature of the melting station to 30°C and the outlet water temperature to 40°C to ensure that the cooling water flow rate is at 1500L / min, and keep the vacuum system open to maintain the vacuum ...

Embodiment 3

[0044] Step 1. Connect the argon gas bottle with the argon-filled cooling pipe before arcing and smelting the ingot with a specification of Φ720mm and a feeding capacity of 5200kg, so as to ensure that the argon gas purity inside the argon gas bottle is not lower than 99.99%, and the air pressure is not lower than 2.5MPa , and ensure that there are no leaks at the pipeline connection, close the flow control valve of the argon gas cylinder, open the vacuum system valve of the vacuum consumable electric arc furnace, adjust the vacuum pressure in the vacuum consumable electric arc furnace to ≤2.0Pa, and the leak rate to ≤1.0Pa / After min, turn on the circulating cooling water, and start the arc to melt the ingot;

[0045] Step 2. After the ingot is smelted and tripped, adjust the inlet water temperature of the melting station to 30°C and the outlet water temperature to 40°C to ensure that the cooling water flow rate is at 1800L / min, and keep the vacuum system open to maintain the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com