A rapid construction method of rubble masonry

A construction method and masonry technology, applied in artificial islands, marine engineering, water conservancy projects, etc., can solve the problems of low operation efficiency, inconvenient mechanized construction, etc., and achieve the effects of convenient operation, simple construction, and accelerated construction speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A rapid construction method of a meal masonry, including the following steps:

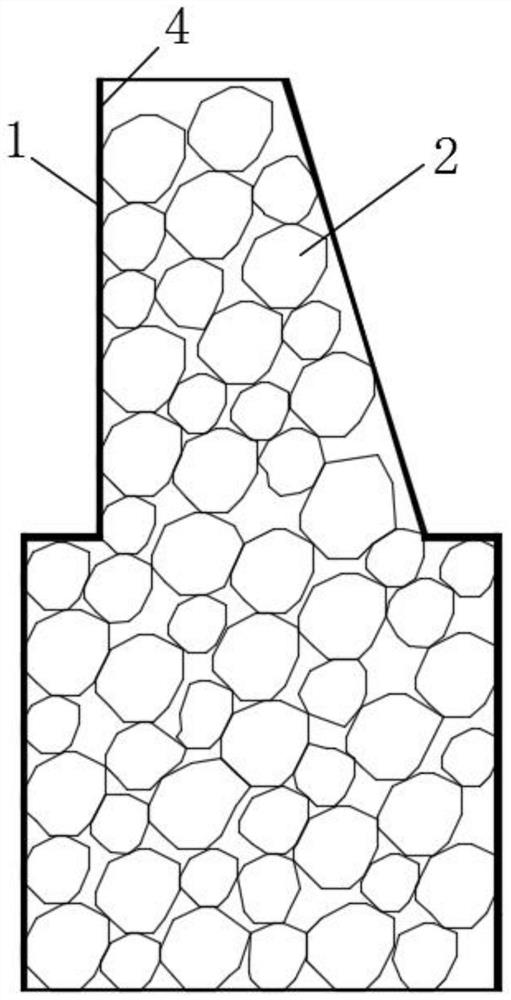

[0033] (1) Formulating a template having a certain stiffness and strength in the stiffness of the masonry structure; the stiffness and strength are sufficient to support the natural stone subsequent filled self-dense mortar is not deformized;

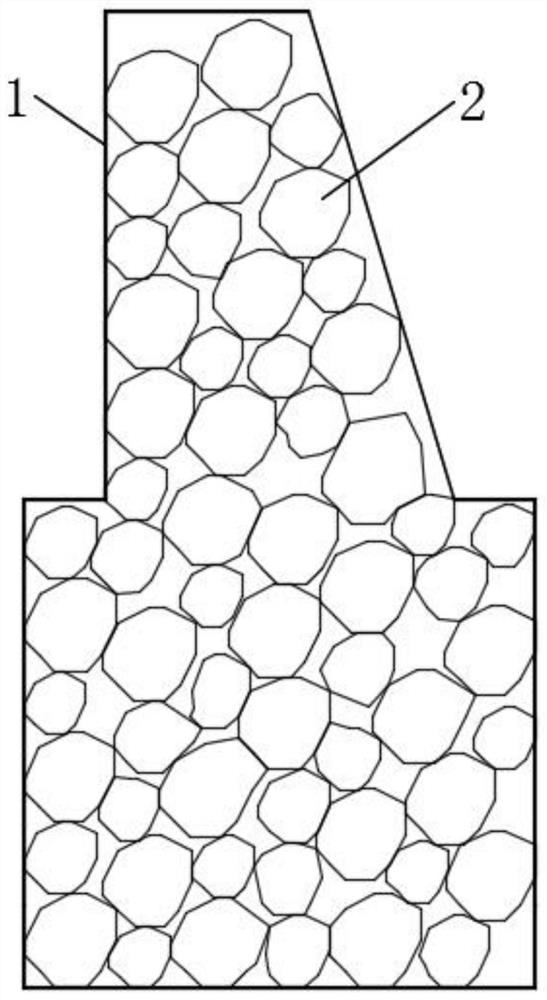

[0034] (2) Stack natural stone in the finished masonry template;

[0035] (3) Fill the prepared self-sufficient mortar to the natural stone gap in the template; the water ash than 0.975 in the dense mortar, the gray bit ratio is 0.27, and the fineness modulus of sand is less than 2.9;

[0036] (4) Self-constructing mortar over time, it will fill the styled shape. When the masonry reaches a certain strength, the template is removed, and the tight masonry is obtained from the dense mortar.

Embodiment 2

[0038] A rapid construction method of landscape masonry, including the following steps:

[0039] (1) Formulating a template having a certain stiffness and strength in the stiffness of the masonry structure; the stiffness and strength are sufficient to support the natural stone subsequent filled self-dense mortar is not deformized;

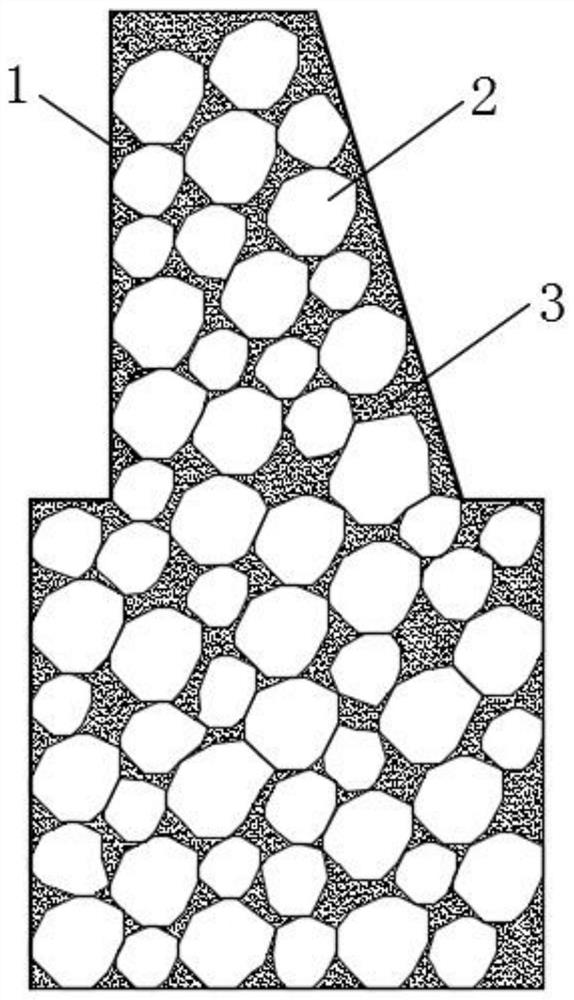

[0040] (2) Place an airbag mold on the inner side of the template, and does not inflate the airbag mold, the airbag mold is flat;

[0041] (3) Stacked natural stone in the finished masonry template; then inflated into the airbag mold, the thickness of the airbag mold is 1 / 3 to 1 / 2 of the minimum stone particle diameter, and no more than 10cm, 5cm Best; the pressure P> dam, ρ after the airbag mold is inflated, and the G is the gravity acceleration, H is the masonry once filling height;

[0042] (4) Filling the prepared self-sufficient mortar to the natural stone gap in the template; the water as ambient than 0.975, the grasted ratio is 0.27, and the fin...

Embodiment 3

[0045] Unlike Example 2, the thickness of the airbag mold was 10 cm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com