Corrosion-resistant dry-grinding-resistant centrifugal pump

A corrosion-resistant, pump casing technology, applied in the field of anti-corrosion centrifugal pump production, can solve the problems of cooling water consumption, cooling water leakage, pump seal failure, etc., to achieve scientific working principle, convenient maintenance and installation, and simple sealing structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

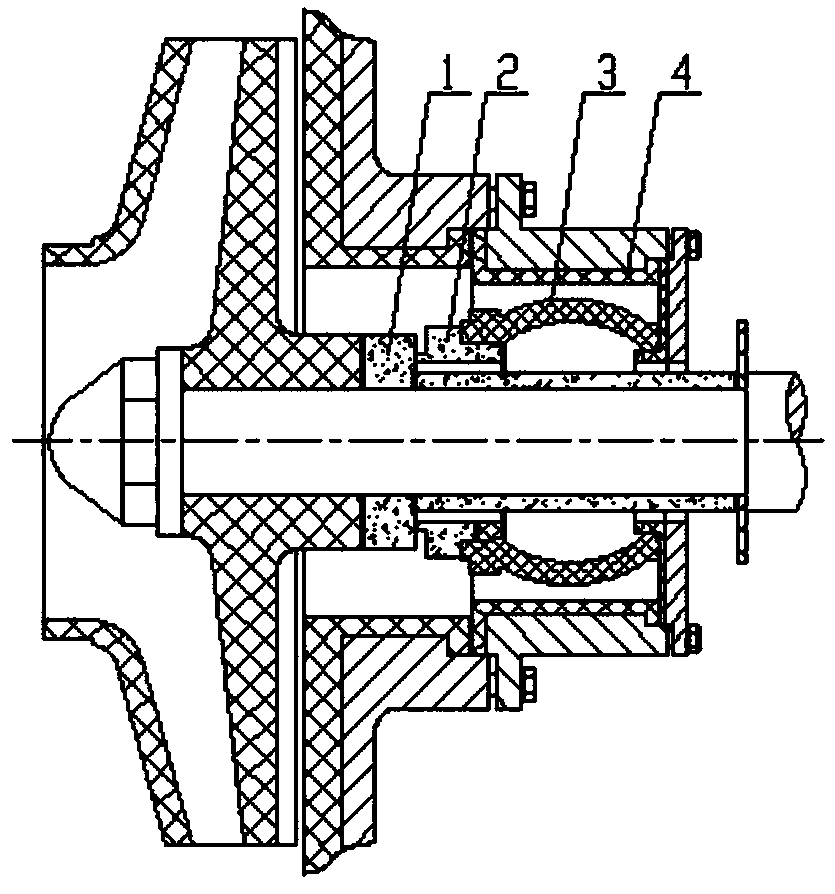

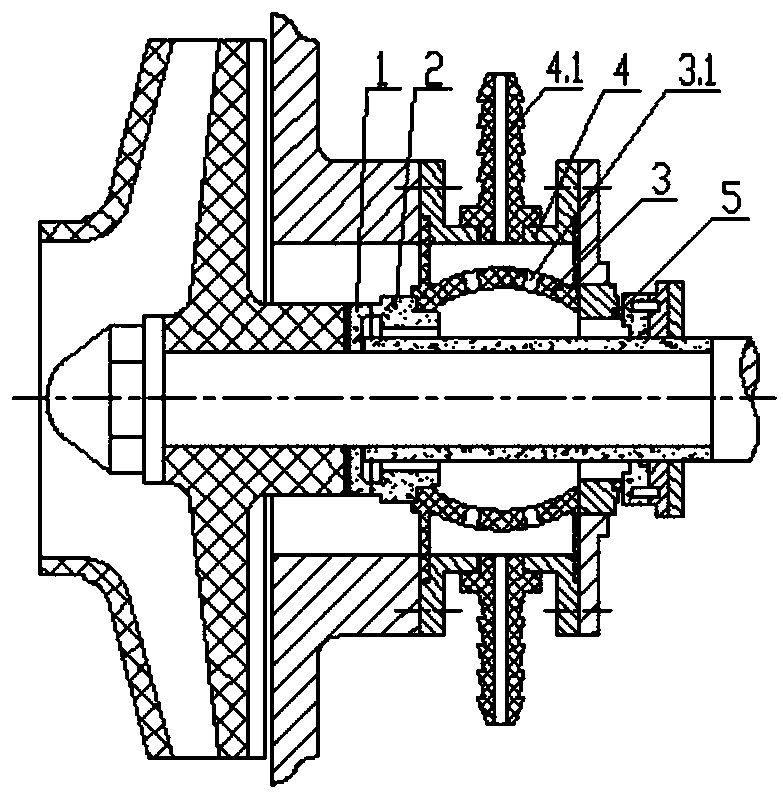

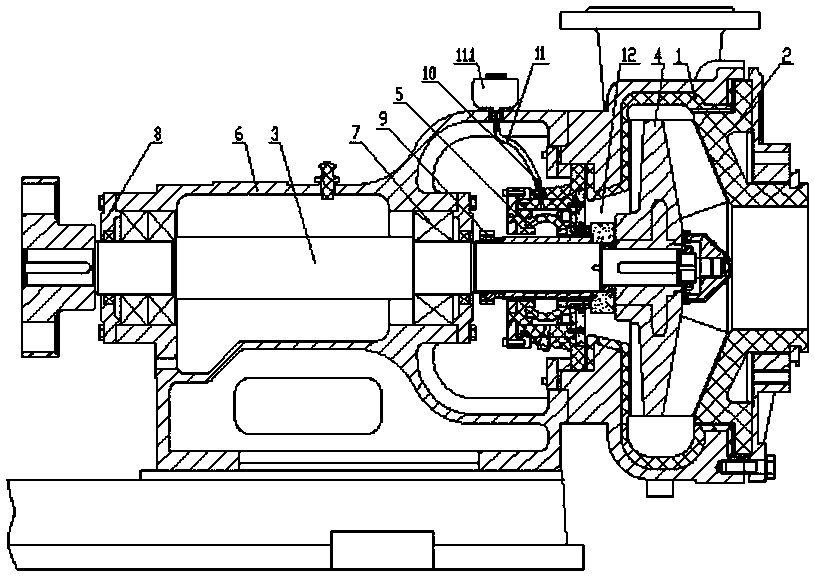

[0043] Embodiment 1: as image 3 , 4 As shown, a corrosion-resistant and anti-dry wear centrifugal pump includes a pump casing 1, a main shaft 3, a shaft seal on the main shaft 3, a bearing seat 6, and an impeller 4 installed at the end of the main shaft 3 and located in the volute cavity of the pump casing 1. The shaft seal includes a seal box assembly and a mechanical seal 5. The mechanical seal 5 includes a static ring 5.2 and a dynamic ring 5.1. The seal box assembly is fixedly connected to the pump casing 1. The shaft sleeve 5.3 is sleeved on the main shaft 3. The dynamic ring 5.1 is clamped and fixed on the Between the shaft sleeve 5.3 and the impeller 4, the moving ring 5.1 is located in the pump cavity and is in contact with the conveying material liquid. The sealing box assembly includes the sealing box 5.5, which is separately connected with the sealing box 5.5. The sealing box presses the rear cover 5.6 and is placed in the sealing box 5.5. The static ring pushes t...

Embodiment 2

[0044] Embodiment 2: as Figure 5 As shown, with reference to Example 1, other features remain unchanged, the static ring pushing elastic ring 5.4 is a straight cylindrical shape with corrugations, and the internal test is provided with a steel compression ring 5.1.3.

Embodiment 3

[0045] Embodiment 3: as Figure 8 As shown, with reference to Embodiment 1, the other features remain unchanged. The end of the shaft sleeve 5.3 near the impeller 4 is provided with a valgus accommodation chamber 5.3.1 for fixing the moving ring 5.1, and the moving ring 5.1 is fixed in the valgus accommodation chamber 5.3.1. The shaft sleeve 5.3 is located on the front side of the sealing box pressure back cover 5.6 and is provided with an anti-rotation and anti-pull-off hole 5.3.3.1 and a groove 5.3.3.2, and a positioning piece 5.1.4 and a positioning screw 5.15 are arranged in the groove 5.3.3.2 The positioning piece 5.1.4 is fixed on the back cover 5.6 of the sealing box, and a fastening screw is arranged in the hole 5.3.3.1 to fix the shaft sleeve 5.3 on the main shaft 3. The concave-convex part 5.3.2 coupled with the moving ring 5.1 is arranged in the eversion accommodation chamber 5.3.1. A sealing member 5.3.4 is provided between the outer peripheral surface of the movi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com