High-safety gastrointestinal motility marker and preparation method thereof

A gastrointestinal motility and high-safety technology, which is applied in the fields of pharmaceutical formulation, compound screening/testing, X-ray contrast agent preparation, etc., can solve problems such as difficulty in barium sulfate dispersion, affecting intestinal safety, and difficulty in observation, so as to improve clinical Application method, improvement of surface hydrophilicity, effect of controlling production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A method for preparing a high-safety gastrointestinal motility marker, comprising the following steps:

[0038] S1. Put TPU and barium sulfate in a weight ratio of 1:0.35, add to the mixer, stir at 1800r / min for 65min, and mix well;

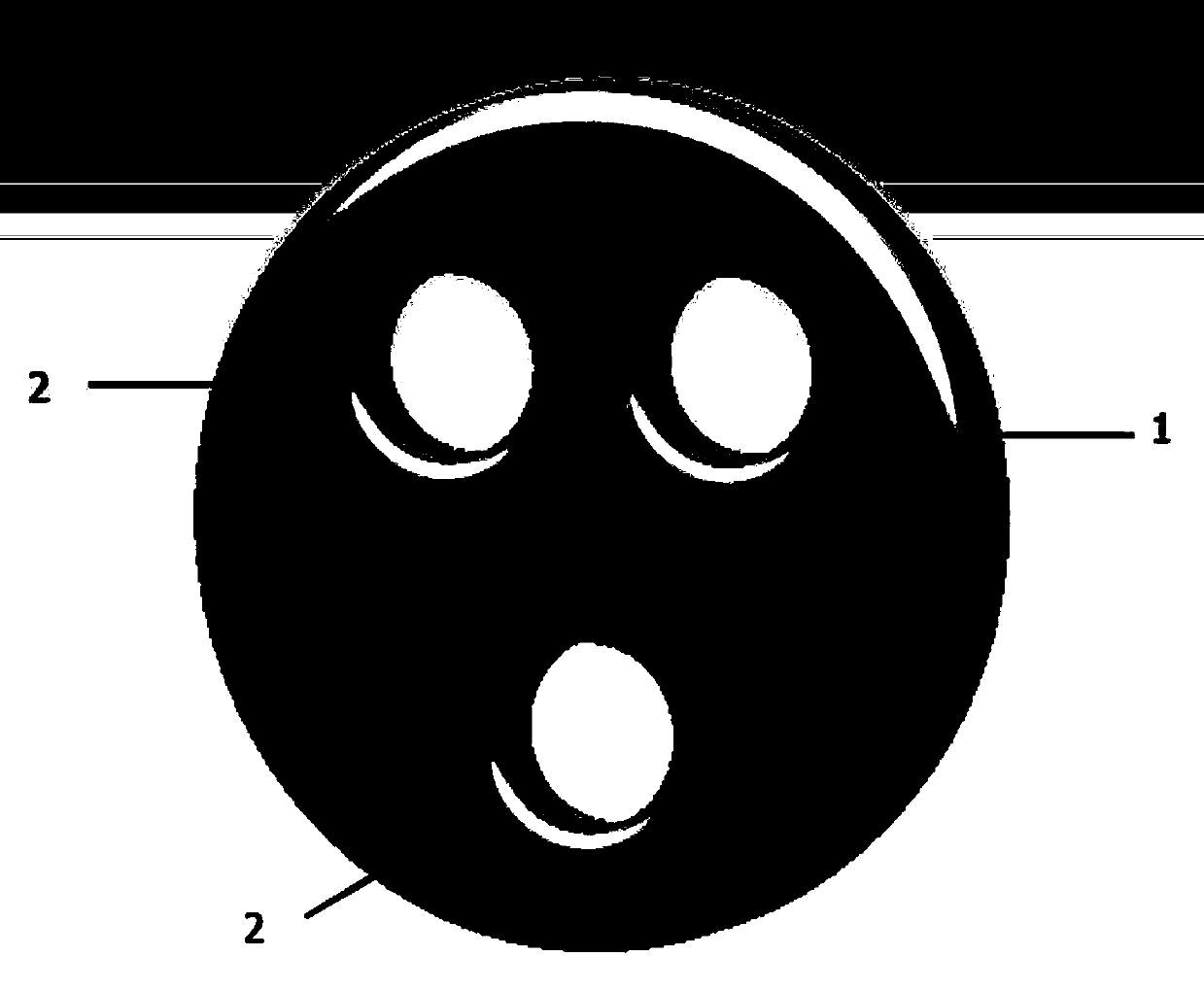

[0039] S2. Put the mixed TPU and barium sulfate into the micro high-pressure injection molding machine, perform high-pressure injection molding at an injection pressure of 240MPa and an injection temperature of 190°C, fully disperse the barium sulfate, and make a mold with a wall thickness of 0.8-1.2mm and a radius R Round corner markers of 0.1-0.3mm;

[0040] S3. Fix the markers on the tooling, use a numerical control spraying machine to evenly spray 10wt% gelatin aqueous solution on the surface of the markers at a spraying speed of 0.4m / min, to obtain target markers, each weighing 18-21mg.

Embodiment 2

[0042] A method for preparing a high-safety gastrointestinal motility marker, comprising the following steps:

[0043] S1. Put TPU and barium sulfate in a weight ratio of 1:0.55, add to the mixer, stir at 2300r / min for 50min, and mix well;

[0044] S2. Put the mixed TPU and barium sulfate into the micro high-pressure injection molding machine, perform high-pressure injection molding at an injection pressure of 360MPa and an injection temperature of 160°C, fully disperse the barium sulfate, and make a mold with a wall thickness of 0.8-1.2mm and a radius R Round corner markers of 0.1-0.3mm;

[0045] S3, fix the marker on the frock, use a numerical control spraying machine, evenly spray 20wt% hydroxypropyl methylcellulose aqueous solution on the surface of the marker with a spraying speed of 0.6m / min, and make the target marker, each grain weight is 18 -21 mg.

Embodiment 3

[0047] A method for preparing a high-safety gastrointestinal motility marker, comprising the following steps:

[0048] S1. Put TPU and barium sulfate in a weight ratio of 1:0.45, add to the mixer, stir at 2000r / min for 60min, and mix well;

[0049] S2. Put the mixed TPU and barium sulfate into the micro high-pressure injection molding machine, perform high-pressure injection molding at an injection pressure of 300MPa and an injection temperature of 165°C, fully disperse the barium sulfate, and make a mold with a wall thickness of 0.8-1.2mm and a radius R Round corner markers of 0.1-0.3mm;

[0050] S3. Fix the marker on the tooling, use a numerical control spraying machine, and evenly spray 15wt% gelatin aqueous solution on the surface of the marker at a spraying speed of 0.5m / min to prepare the target marker, each weighing 18-21mg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com